Trace corrosive gas environmental test box

A corrosive gas, environmental test chamber technology, used in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of in-situ observation, uncontrollable temperature and humidity, and low device accuracy, and achieve a simple structure. , low cost, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

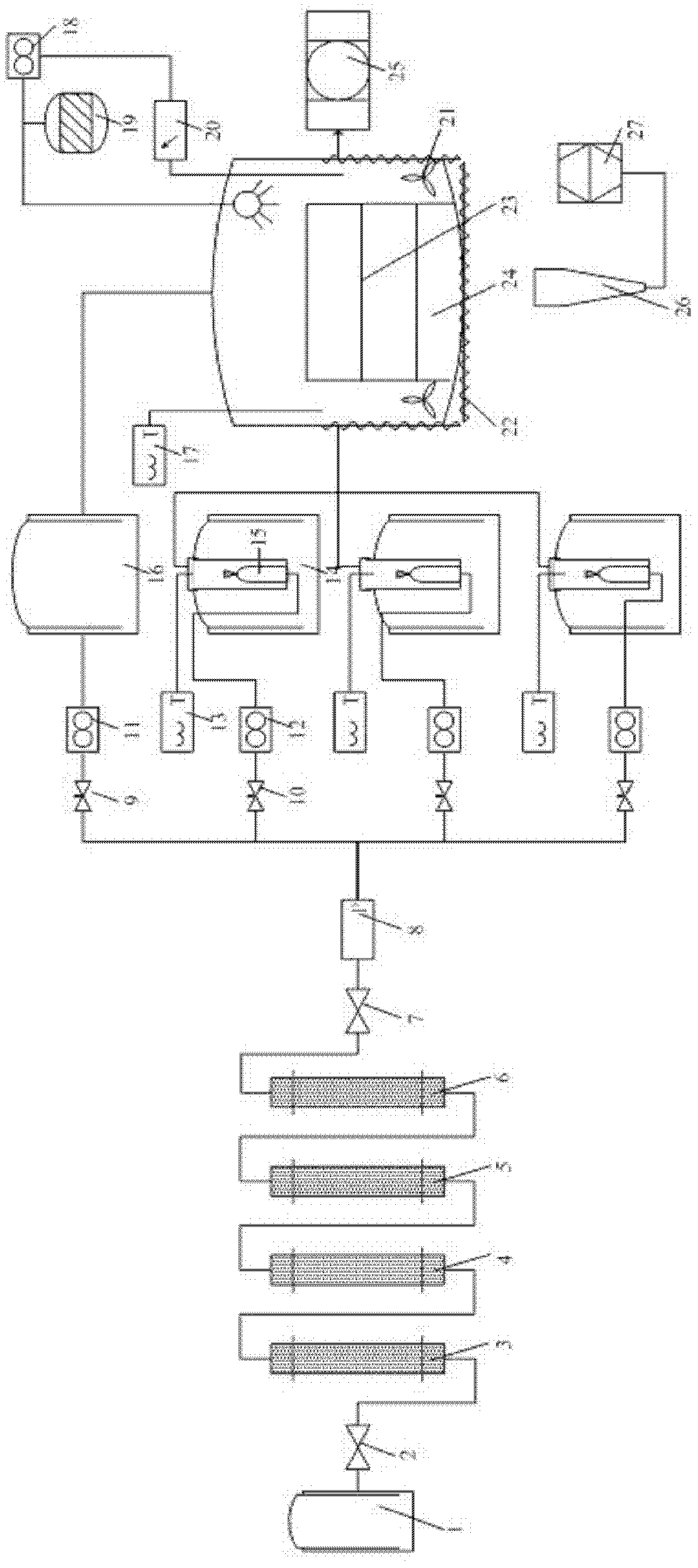

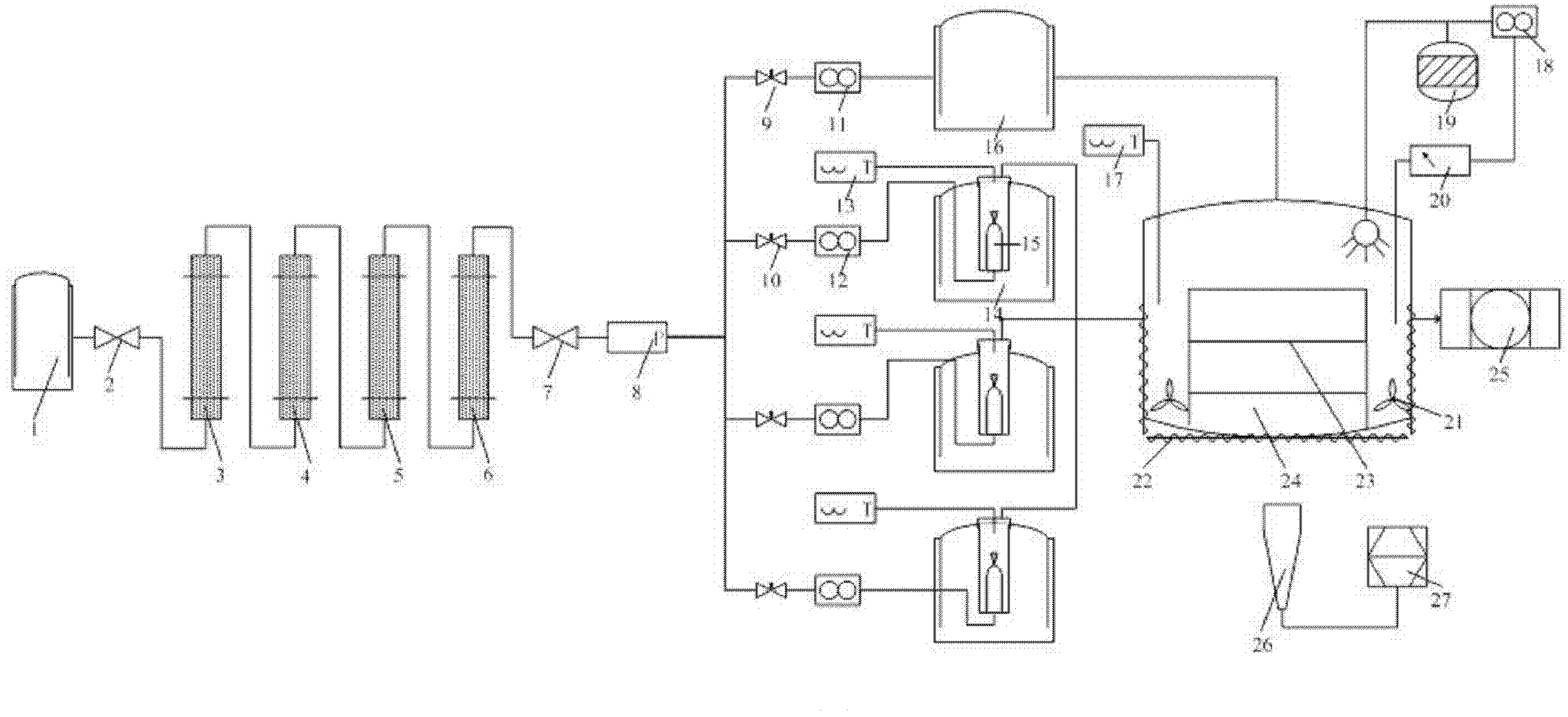

[0032] figure 1 It is an embodiment of the present invention.

[0033] The clean air supply module consists of an air compressor 1, a pressure regulator valve 2, and a drying and purification tube composed of sodium hydroxide 3, color-changing silica gel 4, alkali asbestos 5, molecular sieve 6, pressure regulator valve 7 and pressure gauge 8. The dilution and carrier air is generated by the air compressor 1, and after flowing through the pressure stabilizing valve 2 and the drying and purification pipe, it is divided into four paths and enters the trace corrosive gas generation module.

[0034] One of them passes through the first flow meter 11 with the first needle valve 9 and enters the gas distribution chamber 16 to form a clean air system, which is used as a secondary dilution gas source. The other three paths enter one or more corrosive gas generating systems, and enter the first constant temperature tank 14 through the second flow meter 12 with the first needle valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com