Energy-saving inclined-bottom heating furnace

A technology of inclined bottom heating furnace, which is applied in the direction of heat treatment furnace, furnace, furnace type, etc., can solve the problems of easy loss of heat, high investment cost, inconvenient production management, etc., to reduce the number of shutdown repairs, prolong the service life, The effect of improving the heating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

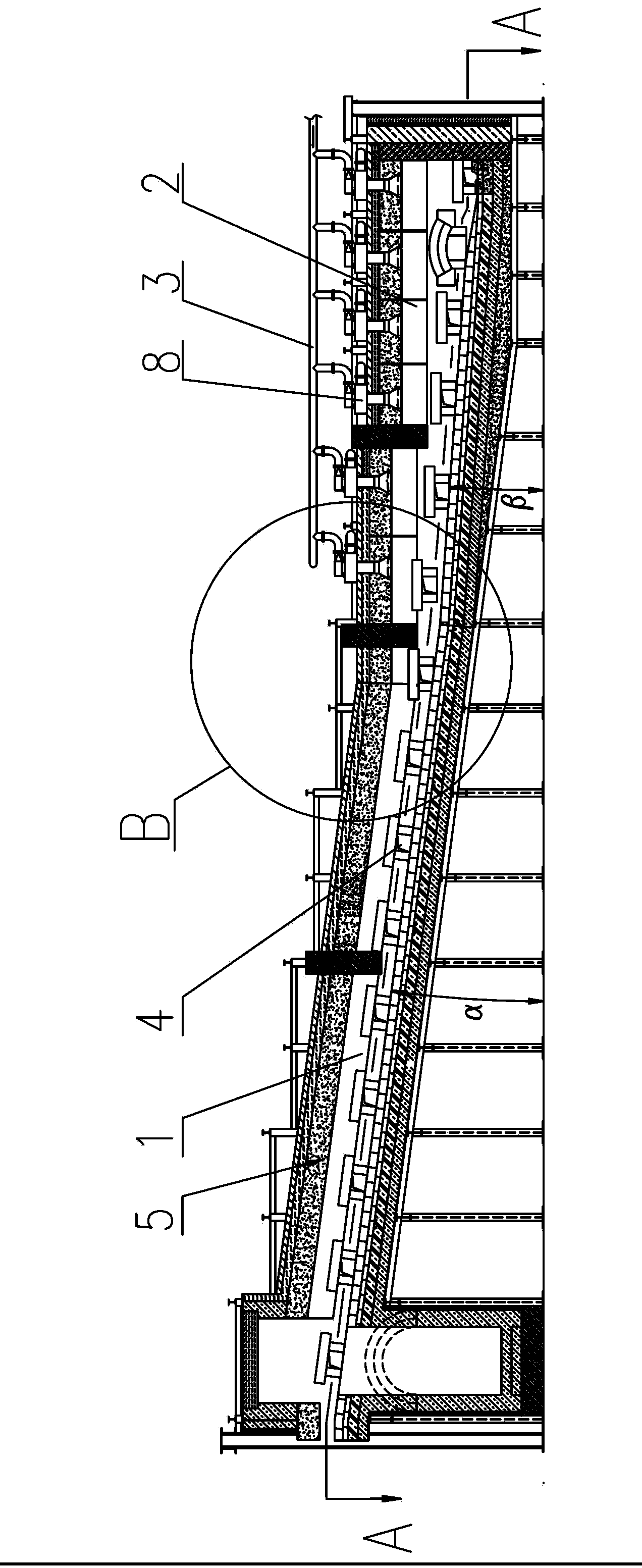

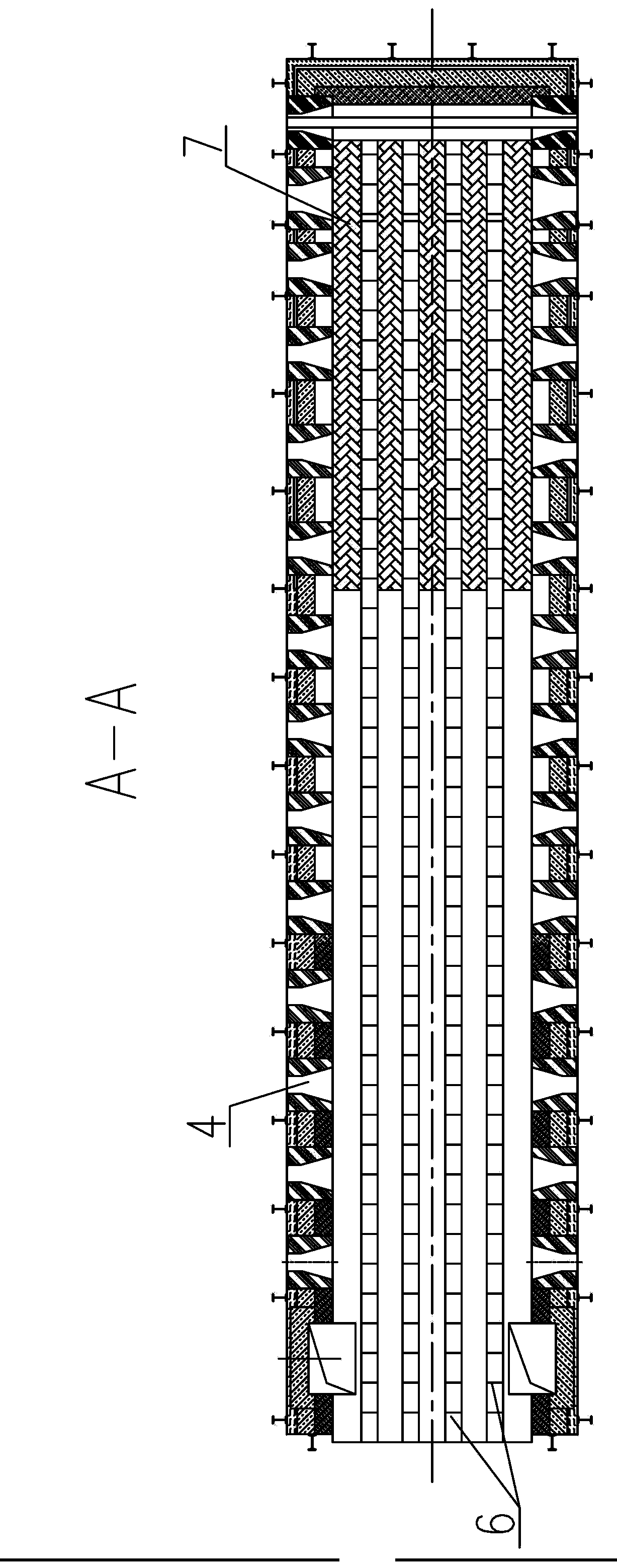

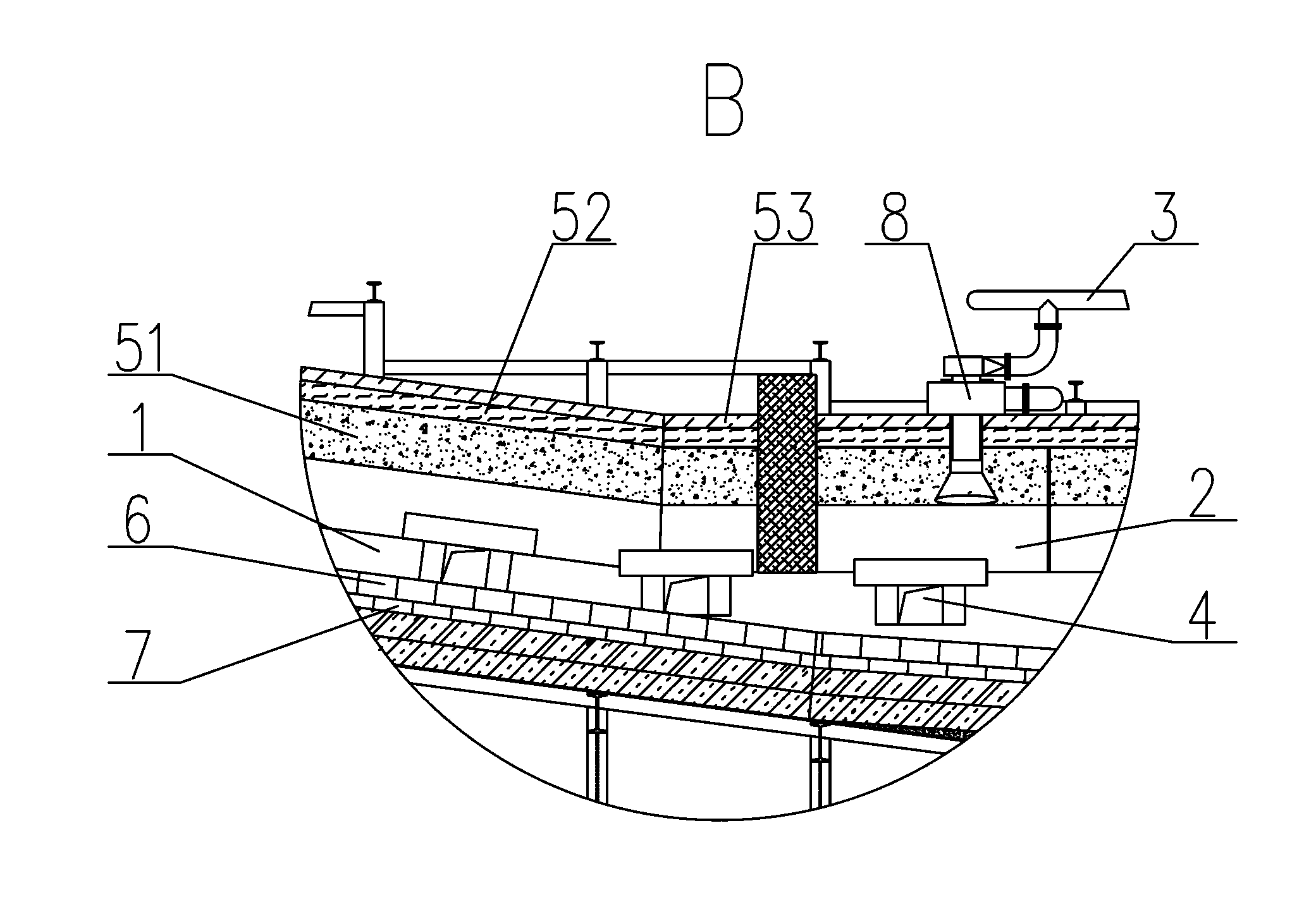

[0026] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0027] Such as figure 1 , figure 2 The best embodiment of the energy-saving inclined-bottom heating furnace shown in the present invention has a furnace, and the furnace is sequentially provided with a downwardly inclined preheating channel 1 and a heating channel 2 starting from the feed inlet, and the heating channel 2 is connected and useful. For the natural gas pipeline 3 that provides fuel; the slope α of the preheating channel 1 is 8°, and the slope β of the heating channel 2 is 4°; there are 28 trumpet-shaped feeding openings 4 on both sides of the furnace , the large mouth of the feeding opening 4 faces inward.

[0028] The natural gas pipeline 3 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com