Slag discharging device for dust collector

A technology of dust collector and slag discharger, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of affecting the furnace condition of the chlorination furnace, the existence of safety hazards, and the inability to operate continuously, and achieve effective It is beneficial to environmental protection, improves equipment operation rate, and avoids the effect of sticking equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

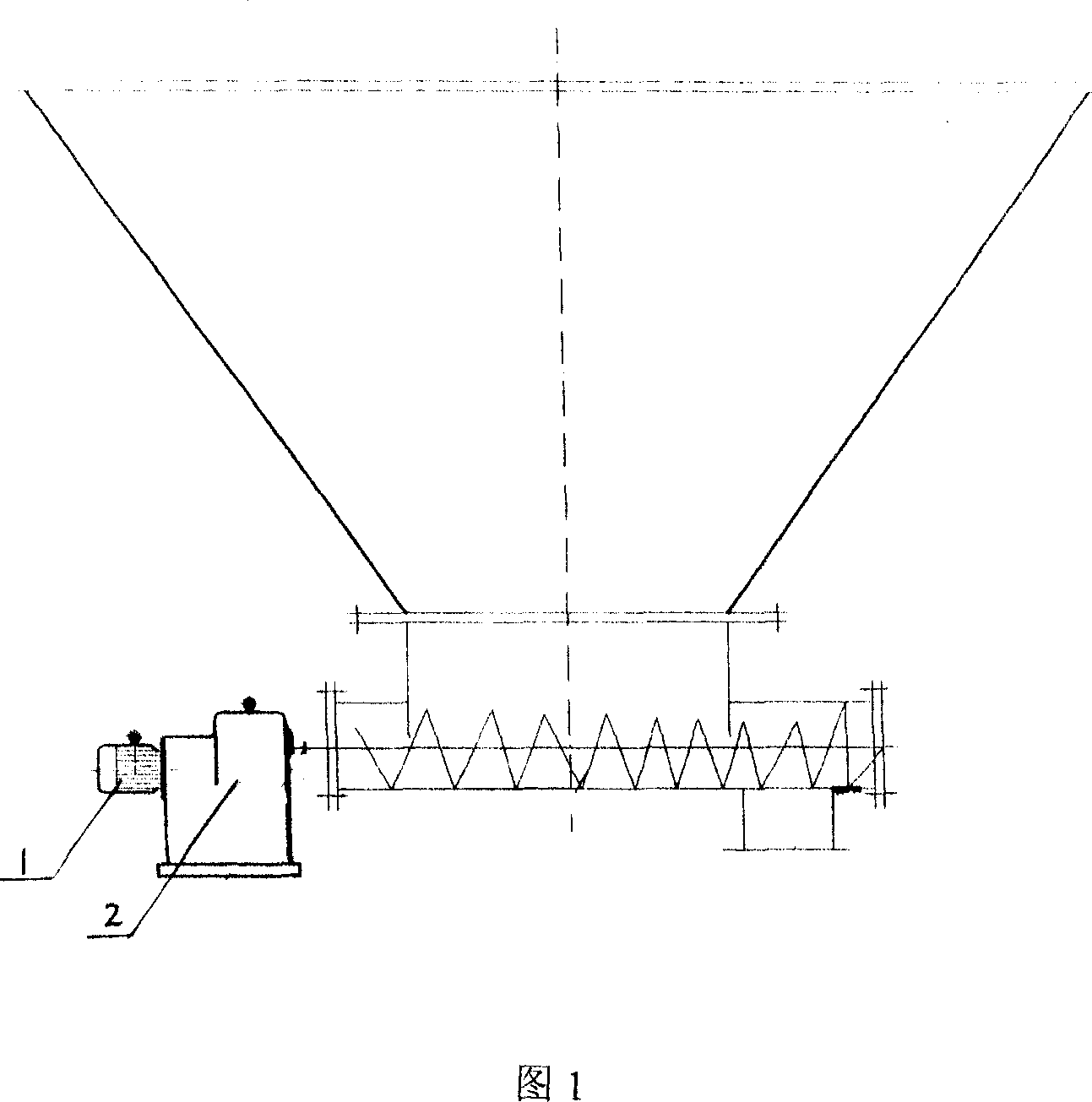

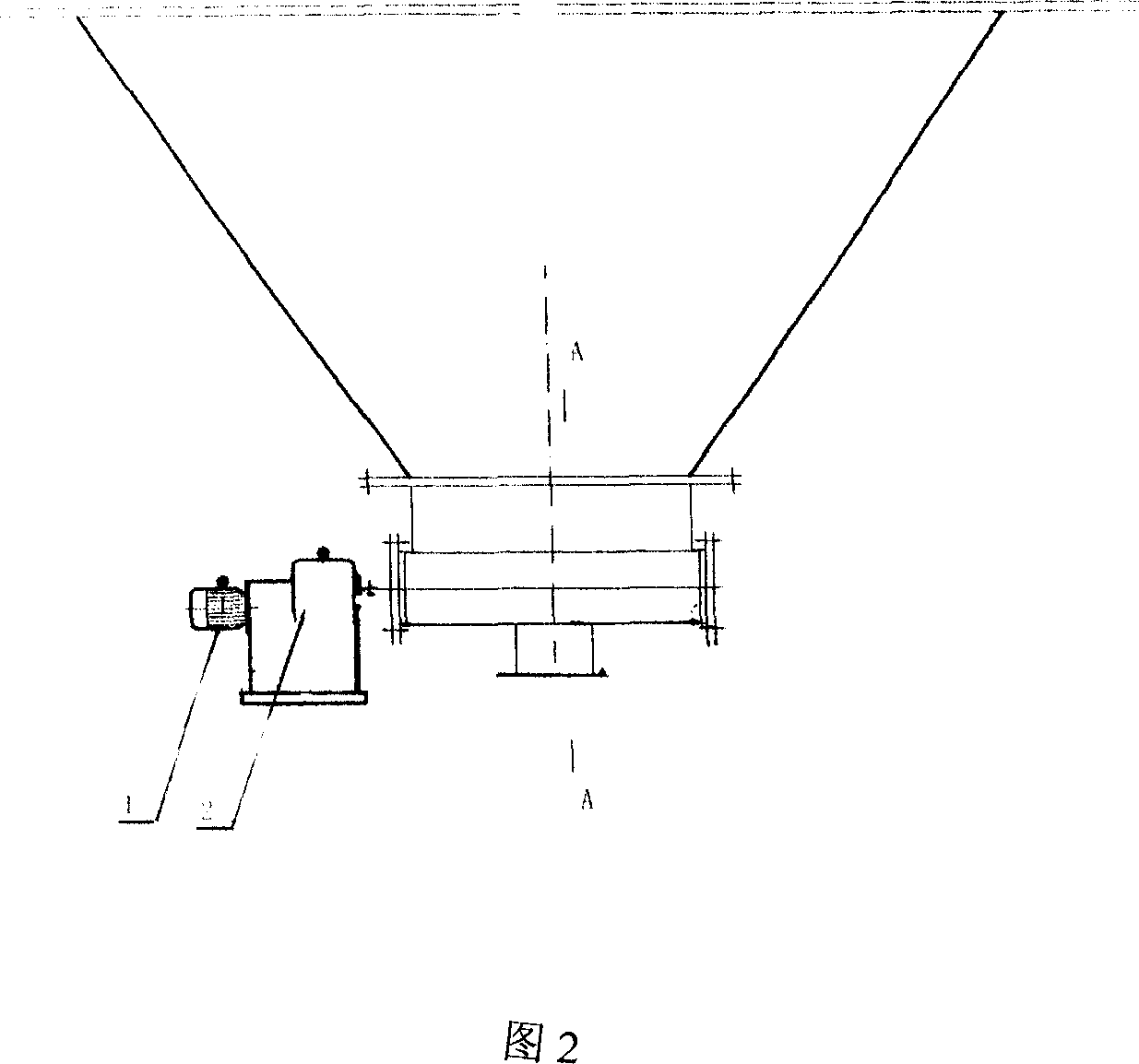

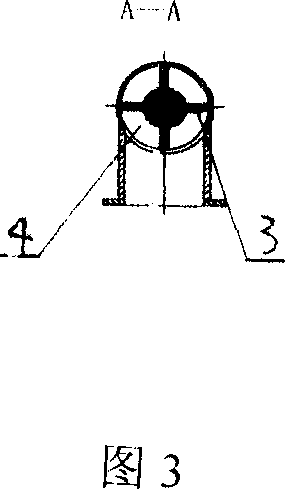

[0012] The slag discharge device of the present invention adopts the method of continuous slag discharge by rotating the slag scraper plate 9. Fig. 4 and Fig. 5 are schematic diagrams of the slag discharge device of the present invention. machine, the slagging device of the dust collector is placed at the bottom of the dust collector 15, the bottom plate of the dust collector 10 is connected with the flange 12 of the dust collector 15 through bolts, sealed with a gasket 11, and the bottom plate of the dust collector 10 has a There is a slag collecting bucket 13; the scraper slag discharger includes a motor 1, a reduction box 2, a garden bevel gear 5 mounted on the output shaft of the reduction box 2, the garden bevel gear 5 meshes with the garden bevel gear 6, and the garden bevel gear 6 is installed on the transmission shaft 8, the garden bevel gear 5 and the garden bevel gear 6 form a garden bevel gear pair 5, 6, the transmission shaft 8 is contained in the bearing box 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com