Slag-back prevention and parallel aeration process for blast furnace

A blast furnace and air supply technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as insufficient performance of the air supply system, unbalanced equipment configuration, and slag filling of blast furnaces to avoid economic losses, The effect of improving the utilization factor and increasing the iron output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

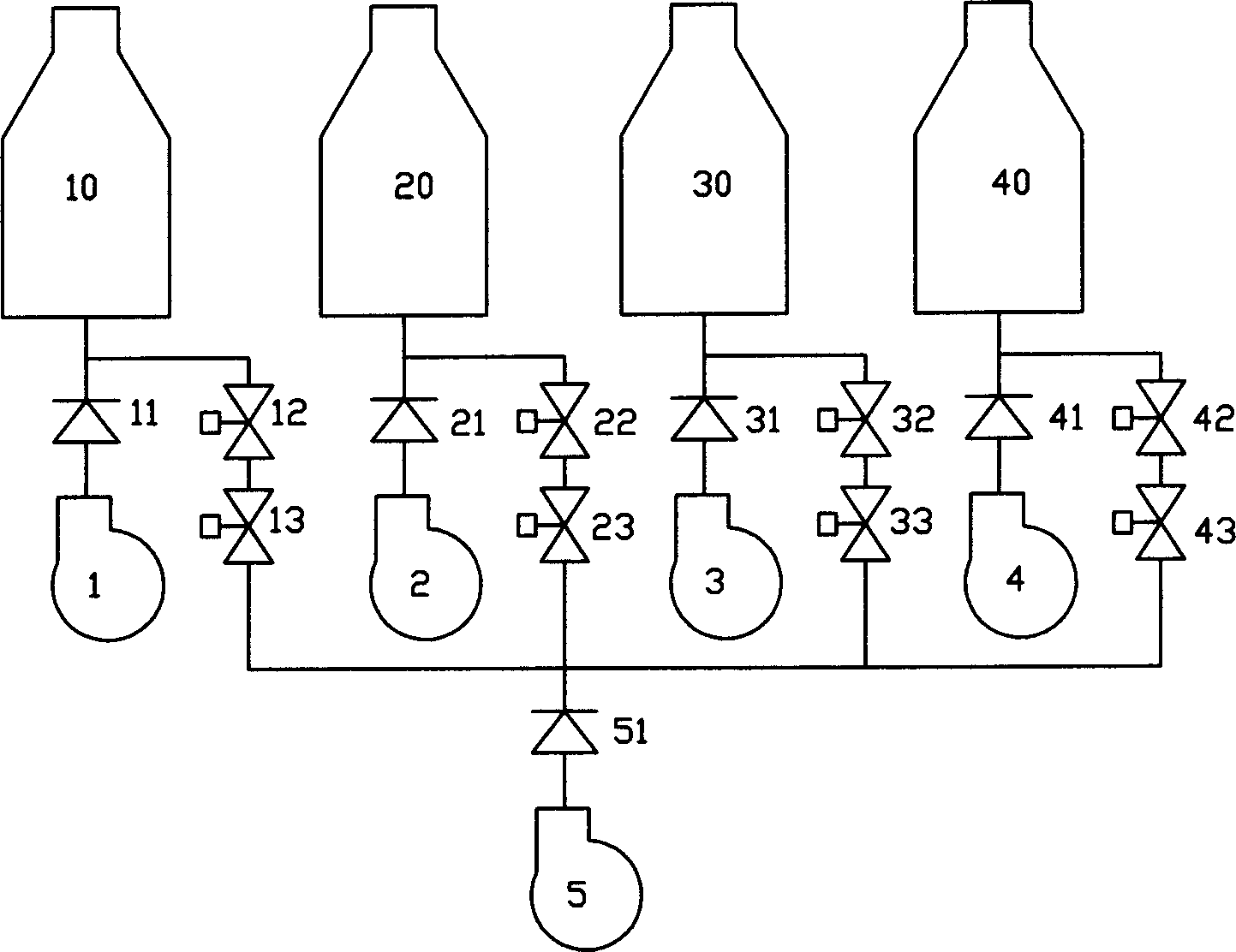

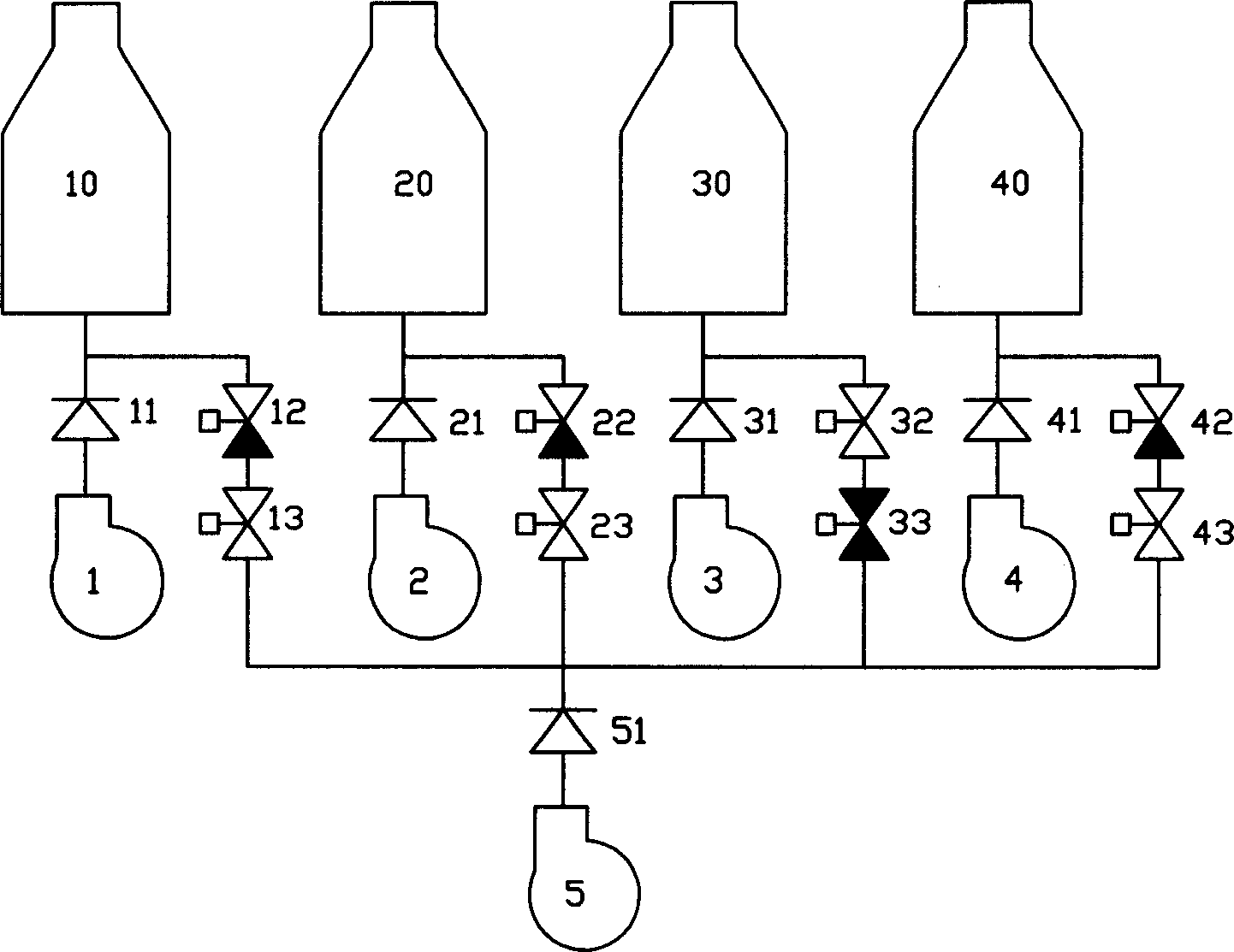

[0023] Example 1: One fan provides parallel auxiliary wind or security wind process for multiple blast furnaces

[0024] Such as figure 1 As shown, the relationship between blast furnace and fan configuration is shown in Table 1. No. 1 fan 1, No. 2 fan 2, No. 3 fan 3, and No. 4 fan 4 are all single main supply fans, respectively No. 1 blast furnace 10 and No. 20. The main air supply for No. 3 blast furnace 30 and No. 4 blast furnace 40, and No. 5 blower fan 5 is a parallel auxiliary supply fan, which can provide auxiliary wind or security wind for some or all blast furnaces in No. 1 to No. 4 blast furnaces at the same time.

[0025] Table 1. Possible configuration relationship between blast furnace and fan

[0026]

[0027] Such as figure 2 As shown, the No. 1 fan 1, the No. 2 fan 2, the No. 3 fan 3 and the No. 4 fan 4 respectively pass through the check valve 11, the check valve 21, the check valve 31, and the check valve 41 to the No. 1 blast furnace 10 a...

Embodiment 2

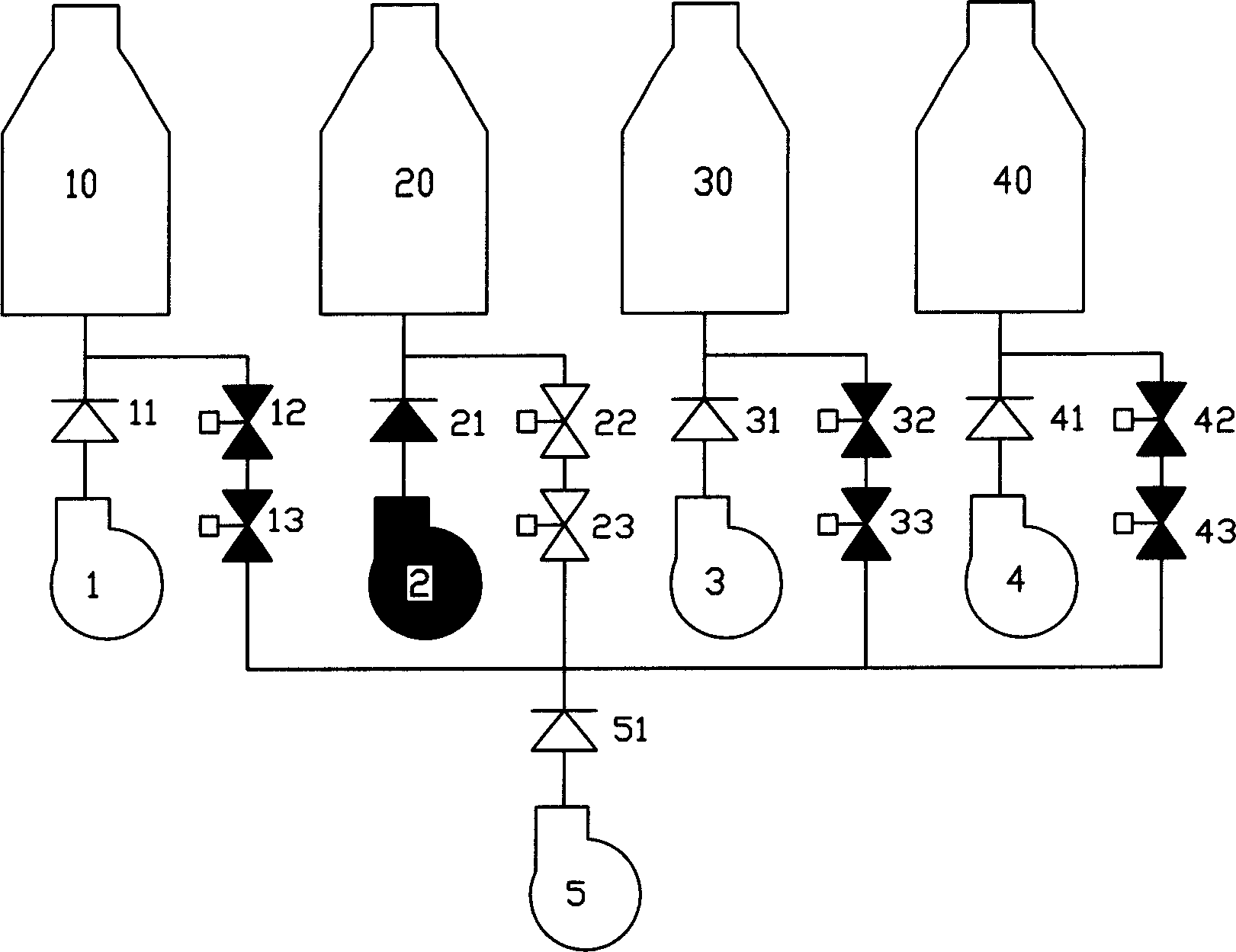

[0030] Embodiment 2 A blower is used as the main blower and at the same time, the excess wind is used to provide parallel auxiliary wind or security wind for multiple blast furnaces.

[0031] Such as Figure 5As shown, No. 1 fan 1, No. 2 fan 2, No. 3 fan 3, and No. 4 fan 4 are single main supply fans, which are respectively the No. 1 blast furnace 10, No. 2 blast furnace 20, No. 3 blast furnace 30, and No. 4 blast furnace 40. Main air supply, No. two blower fan 2 is except being No. two blast furnace 20 main air supply, and its excess wind can provide auxiliary wind or security wind for part or all blast furnaces in other three blast furnaces simultaneously.

[0032] Table 2. Possible configuration relationship between blast furnace and fan

[0033]

[0034] Such as Image 6 As shown, in the present invention, the No. 2 fan 2 provides auxiliary air for the No. 1 blast furnace 10 and provides security air for the No. 3 blast furnace 30 while providing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com