Closed-loop control method for burdening of blast furnace

A closed-loop control and blast furnace technology, applied in the field of blast furnace ironmaking process control system and expert system, production and control of metallurgical process, can solve problems such as easy misoperation, cumbersome appointment execution, heavy tasks, etc., to achieve stable furnace conditions, reduce Fluctuation of slag performance and effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

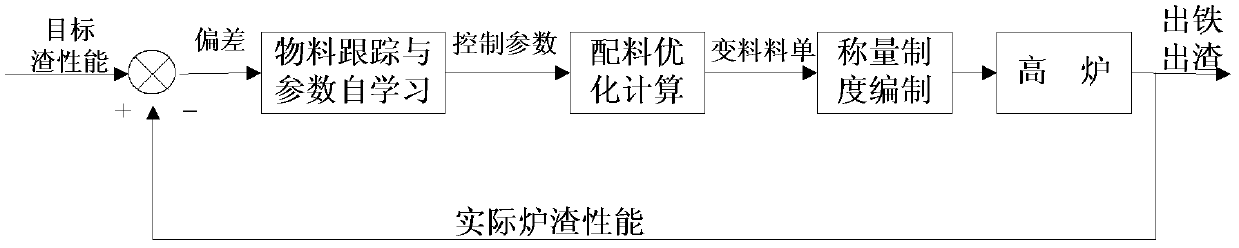

[0026] The present invention relates to processes such as accurate tracking of blast furnace materials, optimal calculation of blast furnace ingredients, preparation of weighing system table, etc., such as figure 1 shown, where:

[0027] 1. Material tracking and parameter self-learning: Realize the whole tracking of the blast furnace charge from the weighing under the trough to the iron slag out of the furnace. The process involves the entire material operation and evolution such as raw material storage and transportation, weighing, charging, furnace operation and tapping. process. Parameter self-learning is based on the tracking results of materials, matching the actual slag performance with the actual batching materials, and identifying the target control parameters required for batching optimization calculation according to the deviation of slag performance.

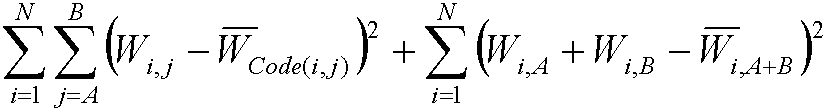

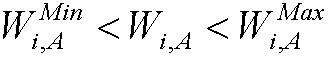

[0028] 2. Batching optimization calculation: According to the target control parameters, raw fuel conditions, equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com