Steel for titanium-boron composite micro alloying afterheat treatment steel bar

A technology of micro-alloying and residual heat treatment, which is applied in the field of hot-rolled ribbed steel for reinforced concrete, can solve the problems of high technical requirements, low production efficiency, and large fluctuations in strength and performance of steel bar surface warping defects, and achieves improved performance. Reinforcement strength, reduced performance fluctuations, and the effect of eliminating warping defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The steel of the present invention is smelted on common steelmaking equipment and continuously poured into billets. Rolling is then carried out on general-purpose steel bar rolling production equipment, waste heat treatment after rolling, rapid surface quenching by cooling device, and then self-tempering using the heat from the core of the steel bar to transfer from the inside to the outside. The steel bars are naturally cooled on the cooling bed, then cut, bundled, and put into storage.

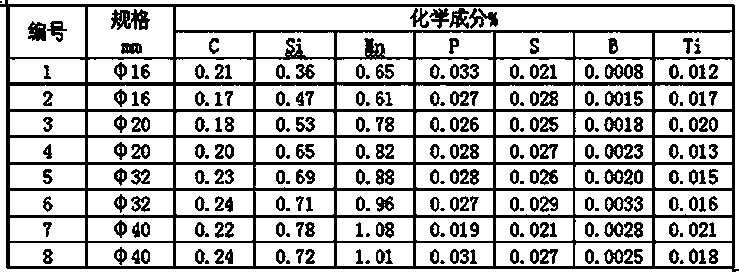

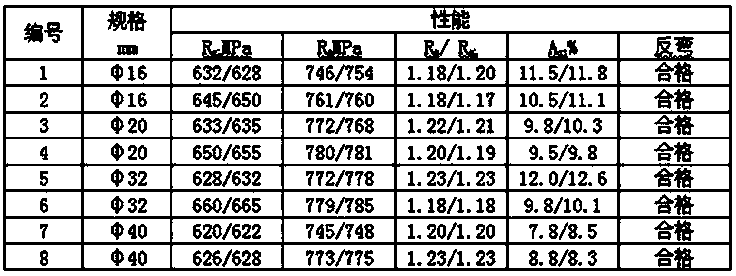

[0017] The composition of each embodiment of the present invention is shown in Table 1, and the production conditions are 50 tons of converter smelting, continuous casting into a 150mm square billet, rolling on a continuous bar rolling mill, waste heat treatment after rolling, and the mechanical properties are shown in Table 2.

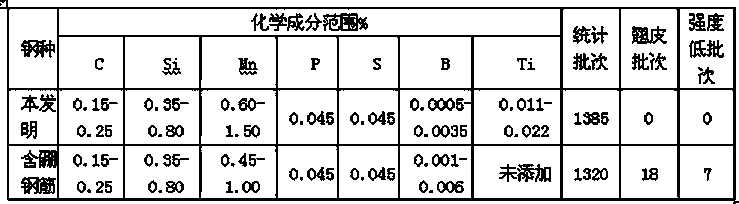

[0018] It can be seen that the boron-titanium alloyed rebar after heat treatment has high strength and toughness, R eL ≥600MPa, strong yield ratio R m / R ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com