Method for preparing cellulosic fiber balls

A technology of cellulose fiber and plant fiber, which is applied in the field of fiber ball preparation, can solve the problems of complex preparation process and organic solvent pollution, and achieve the effects of uniform size distribution, small performance fluctuation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

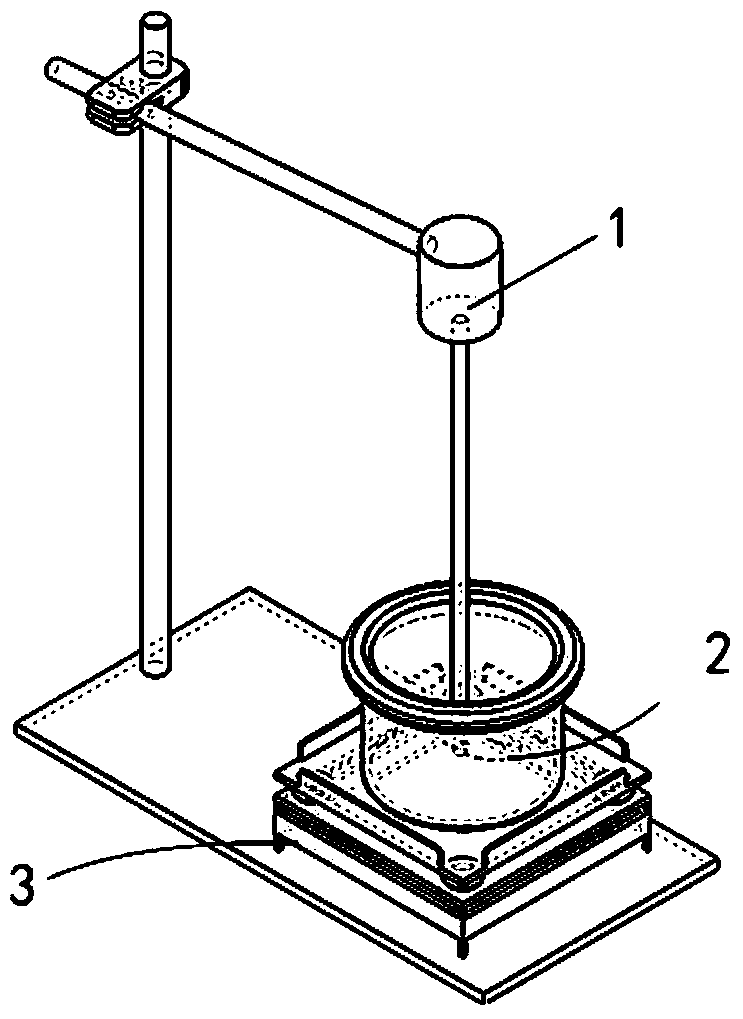

Image

Examples

example 1

[0032] Dry the bamboo fiber, weigh 500g of the dried sample, wrap it with polyethylene filter paper, place it in an extractor, and use a benzene / ethanol solution with a volume ratio of 2:1 to extract at 70°C for 15 hours to fully remove the wax; After the extraction, take out the sample, soak it with 0.6wt% sodium chlorite solution (pH ≈ 4.1), change the solution every 1.5 hours, repeat five times, fully soak to remove lignin, until the cellulose turns white; Take it out and wash it with clean water, then pour it into 6wt.% KOH solution, soak it at room temperature, and then put it in an oil bath at 80°C for a period of time; put the above sample in a vibration dialysis device, use water as the medium, pass Shock dialysis removes alkali and forms cellulose fiber balls, and finally freeze-drying removes water.

[0033] Adsorption performance test: 1) Weigh a certain amount of cellulose fiber balls, put them into a 250mL Erlenmeyer flask, add a certain concentration of methylene...

example 2

[0035] Dry the straw, weigh 300g of the dried sample, wrap it with polyethylene filter paper, place it in an extractor, and use a toluene / acetone solution with a volume ratio of 1:1 to extract at 80°C for 6 hours to fully remove the wax; After the extraction, take out the sample, soak it with 0.6wt% sodium chlorite solution (pH ≈ 3), change the solution every 2 hours, repeat three times, fully soak to remove lignin until the cellulose turns white; take it out with water After cleaning, pour it into 6wt.% KOH solution, soak it at room temperature, and then place it in an oil bath at 80°C for a period of time; put the above sample in a vibration dialysis device, use water as the medium, and remove it by vibration dialysis Alkali and form cellulose fiber balls, and place them in a blast oven at 60°C for 5 hours to fully dry.

example 3

[0037] Dry the ramie fiber, weigh 620g of the dried sample, wrap it with polyethylene filter paper, place it in an extractor, and use a benzene / ethanol solution with a volume ratio of 2:3 to extract at 70°C for 10 hours to fully remove the wax; After the extraction, the sample was taken out, soaked in 0.6wt.% sodium chlorite solution (pH ≈ 3.5), and the solution was changed every 3 hours, repeated five times, fully soaked to remove lignin, until the cellulose turned white; Take it out, remove the residual sodium chlorite by several times of centrifugation, pour the clean cellulose into 6wt.% KOH solution, soak it at room temperature, and then place it in an oil bath at 80°C for a period of time ; Place the above sample in a shock dialysis device, use water as the medium, remove alkali and cellulose fiber balls through shock dialysis, and freeze dry to remove water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com