Material melting model-based power supply control method for arc furnace

A technology for power supply control and electric arc furnace, which is used in electrical program control, electric furnace, program control in sequence/logic controllers, etc., and can solve problems such as operating point optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

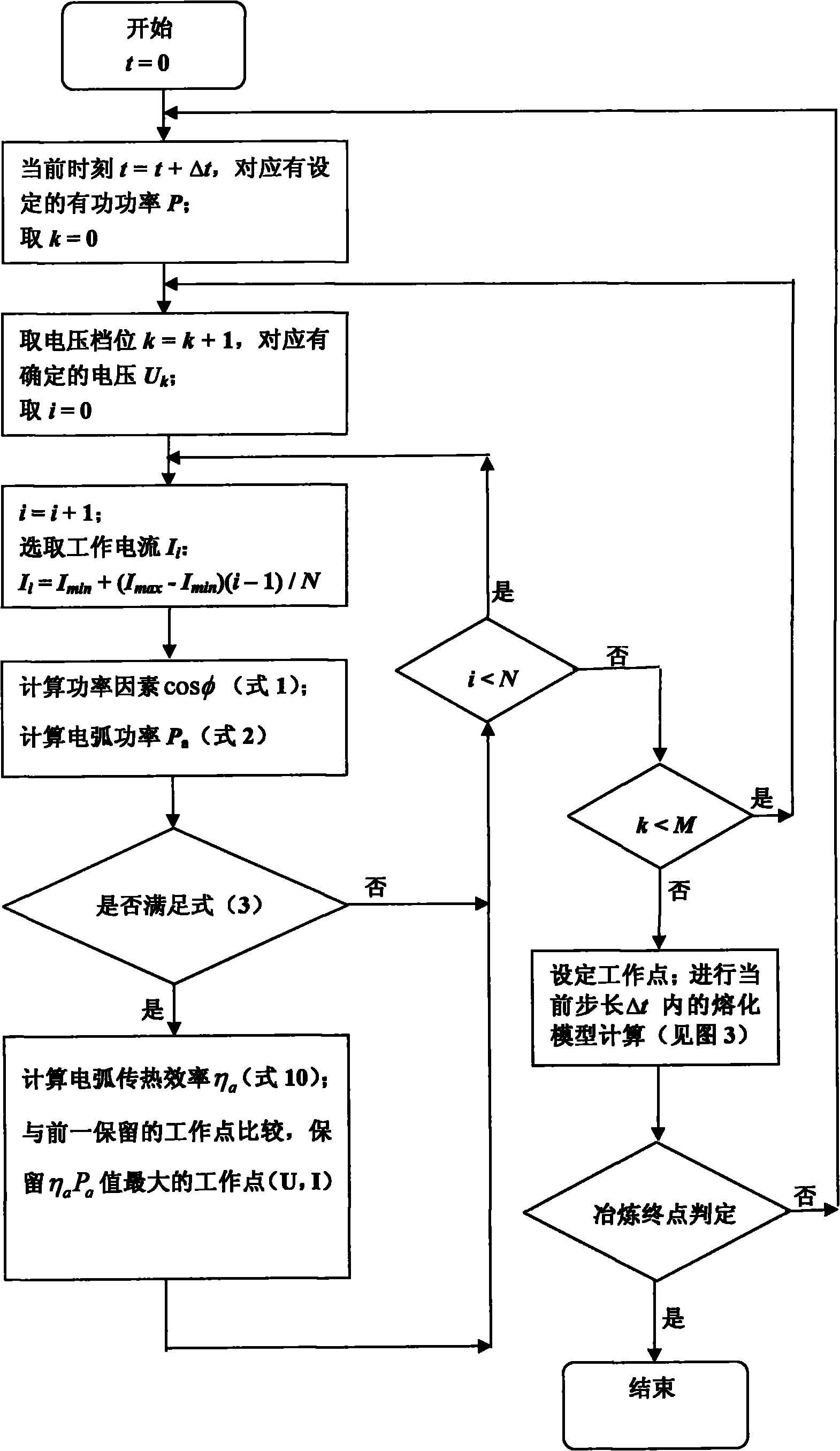

[0065] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings.

[0066] figure 2 A control flow diagram of a first specific embodiment of judging the smelting end point according to the material melting model of the AC electric arc furnace of the present invention is shown. Such as figure 2 As shown, the control method mainly includes:

[0067] Start timing from time t, set the corresponding active power P at time t+Δt, and take k=0;

[0068] Set the voltage gear to k+1, and set the corresponding arc voltage U k , take i=0;

[0069] Choose working current I i , where I i =I min +(I max -I min )(i-1) / N;

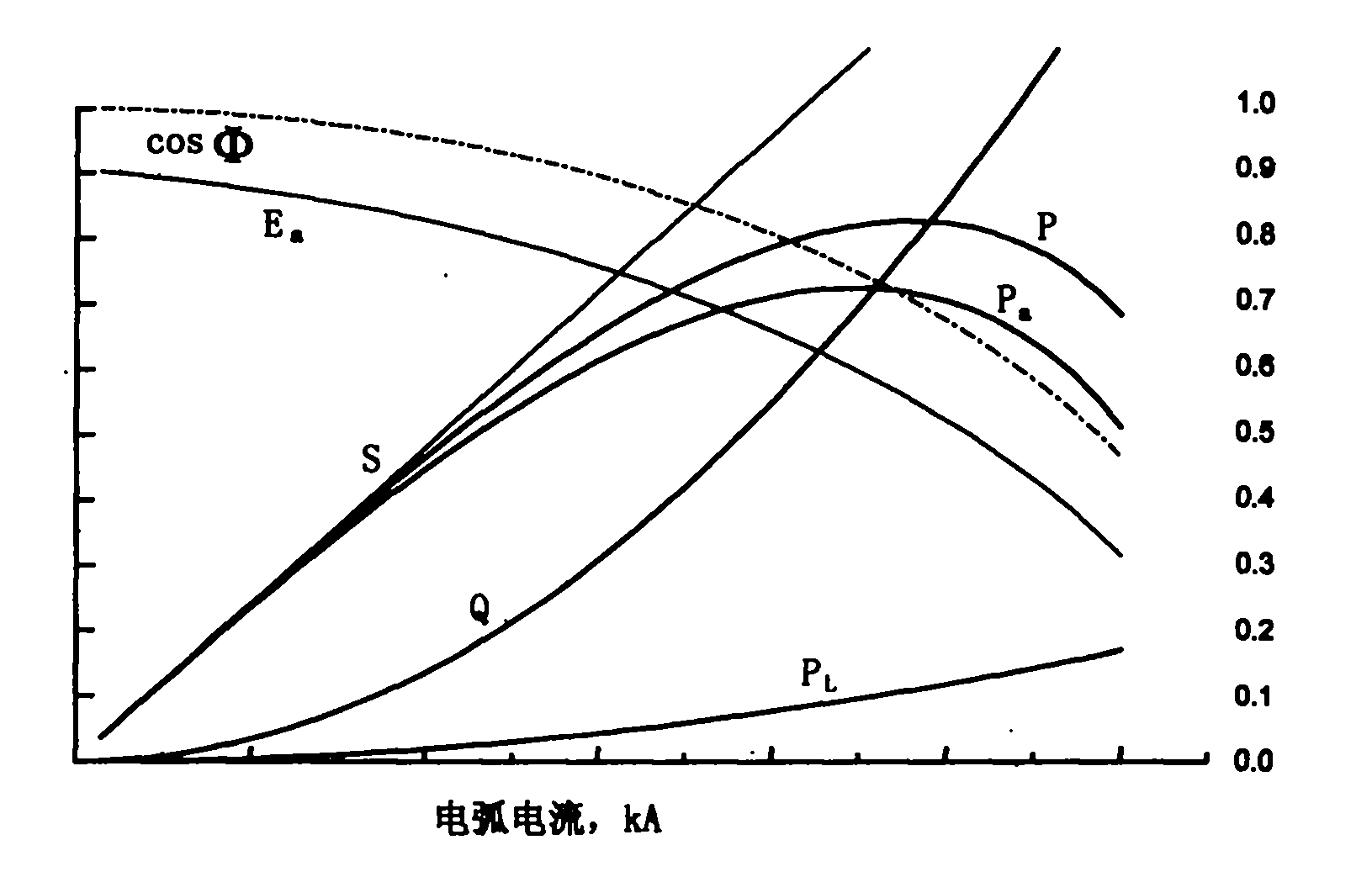

[0070] Use formulas (1) and (2) to calculate power factor cosφ and arc power P a ; the formula is as stated earlier, and P a =3UIcosφ-3I 2 R;

[0071] According to the power factor calculated by the above formulas (1) and (2), judge whether it satisfies the formula (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com