Ozone contact oxidation tank and refinery wastewater advanced treatment method thereof

A technology for ozone contact oxidation and oil refining wastewater, which is applied in the field of water treatment, can solve the problems of reducing the efficiency of ozone oxidation of refractory organic matter, the treatment effect of refractory COD is not obvious, and the biodegradability of wastewater is not improved, so as to avoid the increase of SS in the effluent. , to avoid short flow of water and improve the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

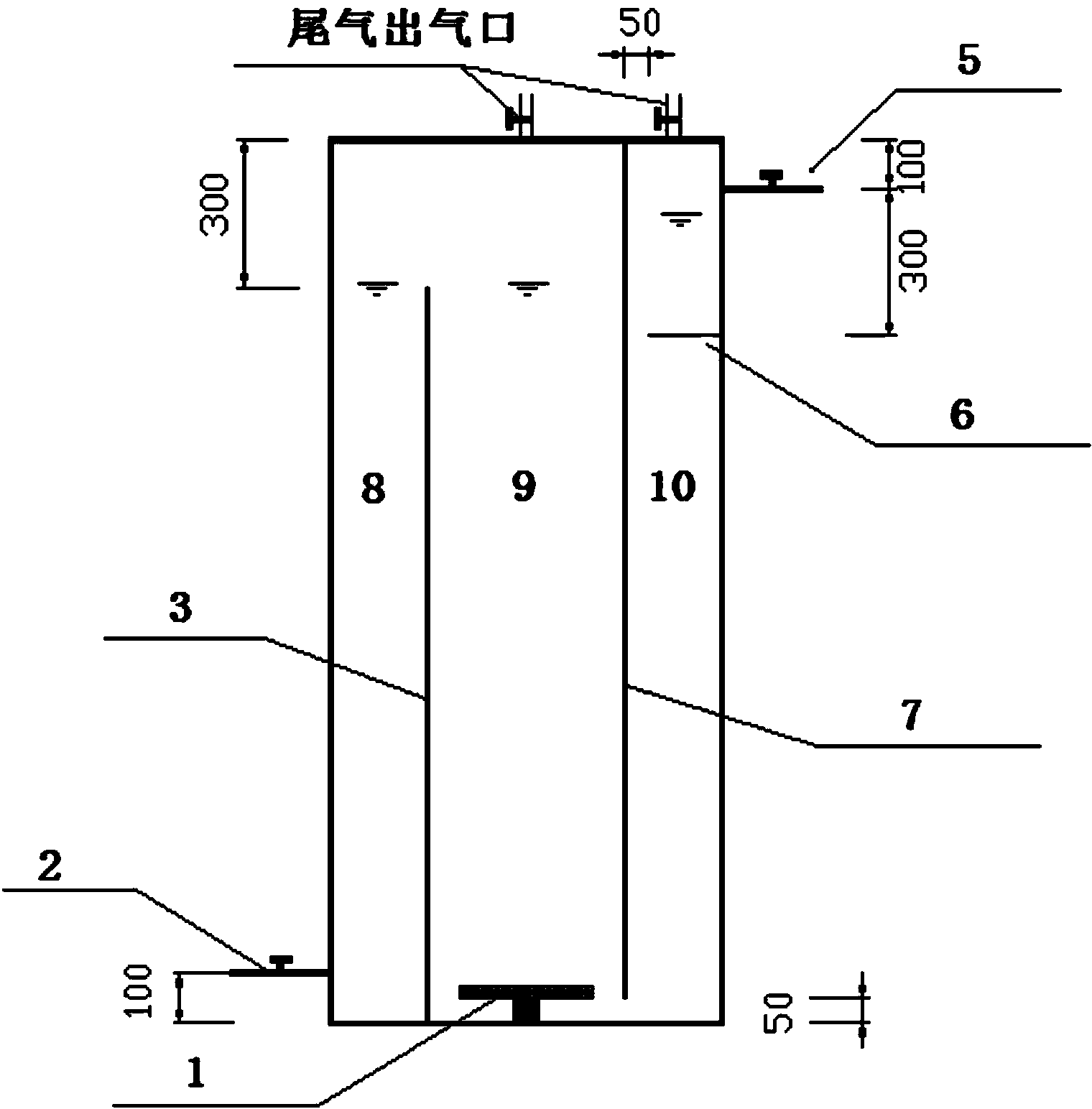

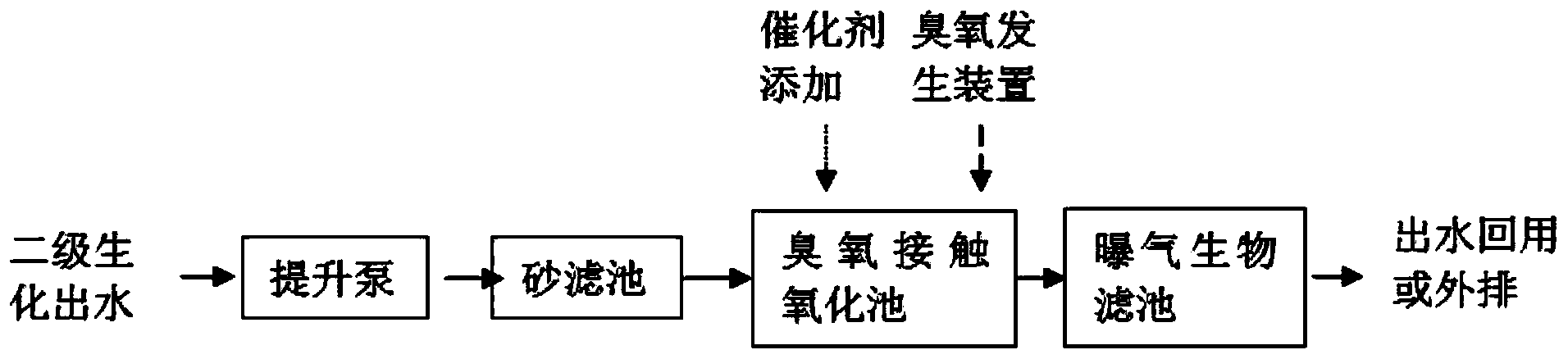

[0034] Such as figure 2 , a refinery 300m 3 / h Refinery wastewater undergoes grit settling→regulation→oil separation→primary and secondary flotation→activated sludge process→secondary sedimentation tank after conventional treatment, and the effluent is the refinery wastewater after secondary biochemical treatment, generally called secondary Biochemical effluent, the water quality index is COD120mg / L, BOD 5 20mg / L, suspended matter SS150mg / L.

[0035] Use sand filter to filter the above-mentioned secondary biochemical effluent, the effective volume of the sand filter is 204m 3 ,Add Φ0.5~1.0mm, Φ1.0~2.0mm and Φ2.0~4.0mm quartz sand filter materials (commercially available) in the filter from top to bottom, the hydraulic retention time is 40min, and the average filtration rate is 7.5 m / h. More than 80% of SS in the secondary biochemical effluent can be removed by quartz sand filtration to ensure that the SS in the ozone oxidation tank does not exceed 30mg / L, so as to avoid t...

Embodiment 2

[0040] The volume of refinery wastewater in a petrochemical refinery is 650m 3 / h, using adjustment-oil separation-vortex concave air flotation-dissolved air flotation-activated sludge treatment, the treated effluent COD is 106mg / L, BOD 5 It is 19mg / L, and SS is 120mg / L. Adopt the various steps and methods mentioned in the content of this recipe in turn, and carry out filtration pretreatment with a sand filter. The hydraulic retention time of the sand filter is 30 minutes, the backwash time period is 48 hours, and the SS after treatment is 22mg / L. The effluent from the sand filter enters the ozone contact oxidation tank. Under the catalytic action of the catalyst, the hydroxyl radicals generated by the decomposition of the ozone will produce intermediate products such as acetic acid and propionic acid from the refractory pollutants. The dosage of the catalyst ferrous sulfate is 3mg / L, Suspended filler is added to the ozone contact oxidation tank to increase the gas-liquid co...

Embodiment 3

[0043] The volume of refinery wastewater in a petrochemical refinery is 400m 3 / h, adopt grit settling→adjustment→oil separation→primary and secondary flotation→oxidation ditch→secondary settling tank for conventional treatment, the COD of the treated secondary effluent is 98mg / L, BOD 5 It is 14mg / L, and SS is 137mg / L. Adopt the steps and methods mentioned in the content part of this recipe successively, and carry out filtration pretreatment with a sand filter, the hydraulic retention time of the sand filter is 45min, and the SS after treatment is 30mg / L. The effluent from the sand filter enters the ozone contact oxidation tank. Under the catalytic action of the catalyst, the hydroxyl radicals generated by the decomposition of the ozone will produce intermediate products such as acetic acid and propionic acid from the refractory pollutants. The dosage of the catalyst ferrous sulfate is 2mg / L, Suspended filler is added to the ozone contact oxidation tank to increase the gas-l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com