MBBR and oil refining wastewater treatment system

A reactor and wastewater technology, which is applied in natural water body treatment, water treatment parameter control, biological water/sewage treatment, etc., can solve the problems of increasing water treatment costs and reducing the economic benefits of water treatment processes, and achieves low operating costs and guarantees. The effect of stable effluent quality and strong decarbonization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In this example, the treatment object is the oil refinery wastewater produced by a certain factory. In the oil refinery wastewater, COD Cr The concentration is 3000mg / L, BOD 5 The concentration of sulfide is 1050mg / L, the concentration of sulfide is 35mg / L, the concentration of petroleum substances is 3000-5000mg / L, the concentration of volatile phenolic substances is 50mg / L, the concentration of ammonia nitrogen is 70mg / L, and the concentration of SS is 700mg / L.

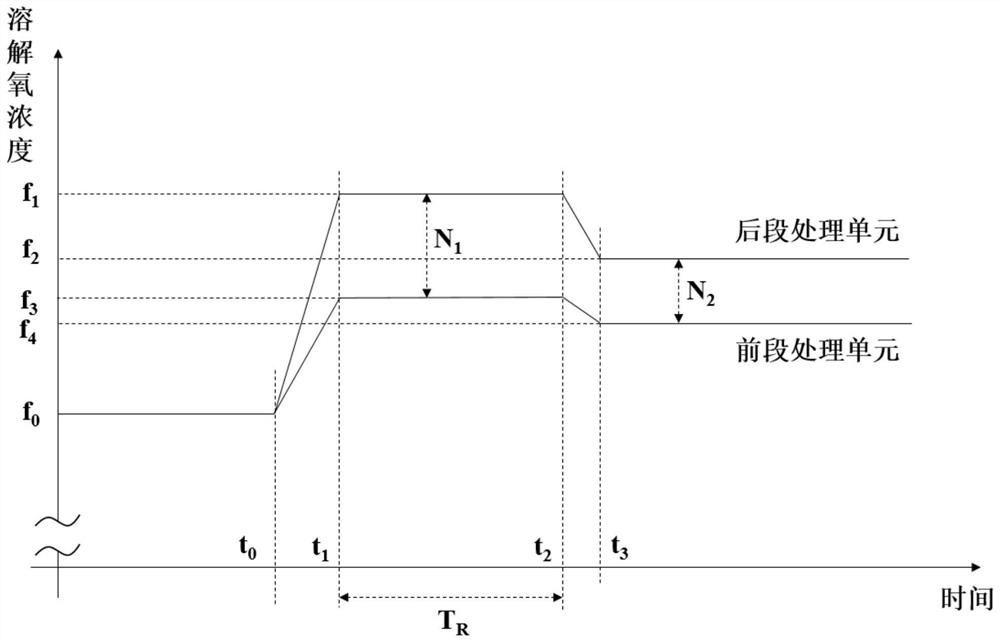

[0054] In this example, if figure 1 As shown, the pretreatment module includes a grid channel, a water collection tank, a regulating homogeneous tank, an advection oil separation tank, a vortex concave air flotation tank and a dissolved air flotation tank connected in sequence. The anaerobic treatment module is arranged at the water outlet of the pretreatment module, and the anaerobic treatment module in this embodiment is A pool. The aerobic treatment module is arranged at the water outlet of the A pool, a...

Embodiment 2

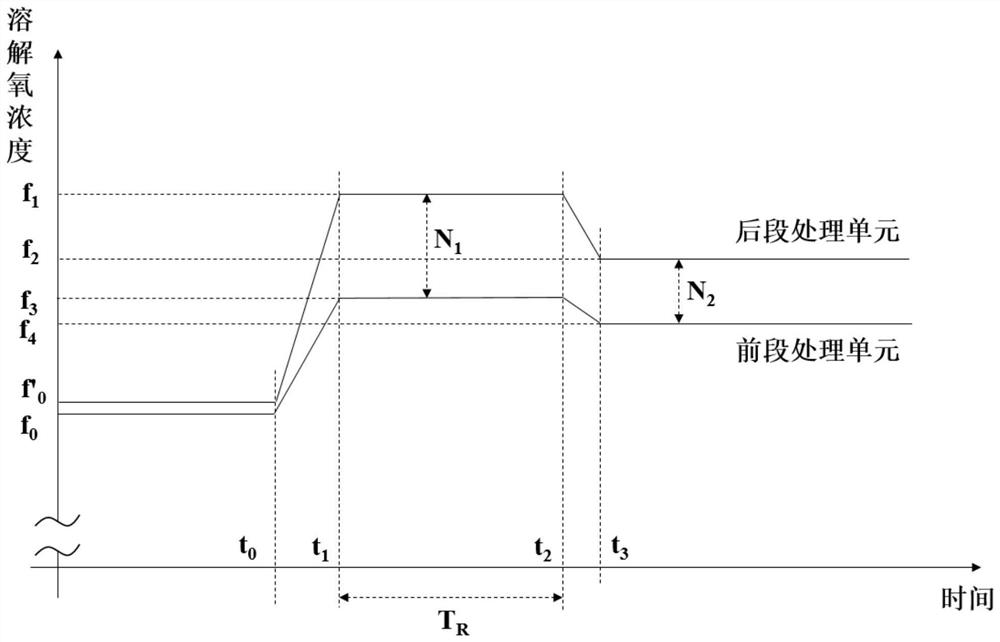

[0068] The basic content of this embodiment is the same as that of Embodiment 1, except that in this embodiment, the volume ratio of the front-end processing unit and the back-end processing unit is 3:1. Control the wastewater flow of the front-end treatment unit to 150m 3 / h, the average concentration of DO is 2mg / L; the wastewater flow rate of the post-processing unit is controlled to be 200m 3 / h, the average concentration of DO was 2.6mg / L. Adjust the reflux ratio of the sludge so that the sludge concentration in the MBBR tank is 3.1g / L, and the pH is about 7.1 at this time. In this embodiment, the dosage of COD-degrading bacteria is 100 g of bacterial agent per ton of wastewater, and the dosage of aerobic nitrifying bacteria is 0.7 g of bacterial agent per ton of wastewater. Adjuvants used in this example are shown in Table 3.

[0069] Table 3 Example 2 Adjuvant Addition Table

[0070] Composition index parameter Vitamin E 6000mg / L Vitamin B1 ...

Embodiment 3

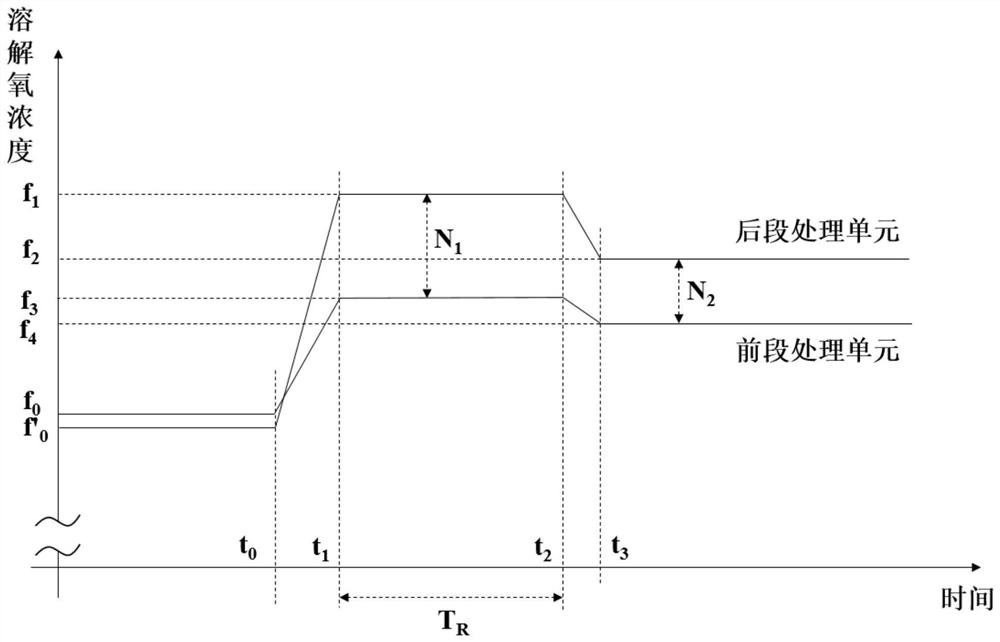

[0076] The basic content of this embodiment is the same as that of Embodiment 1, the difference is that in this embodiment, the volume ratio of the front-stage processing unit and the rear-stage processing unit is 4:1. Control the wastewater flow of the front-end treatment unit to 140m 3 / h, the average concentration of DO is 1.5mg / L; the wastewater flow rate of the control post-processing unit is 200m 3 / h, the average concentration of DO was 2.3mg / L. Adjust the reflux ratio of the sludge so that the sludge concentration in the MBBR tank is 3.1g / L, and the pH is about 7.1 at this time. In the present embodiment, the dosage of COD degrading bacteria is to add 25g bacterial agent per ton of wastewater, and the dosage of aerobic nitrifying bacteria is to add 0.5g bacterial agent per ton of wastewater. The auxiliary agents used in the present embodiment are shown in Table 5 Show.

[0077] Table 5 Example 3 Auxiliary Addition Table

[0078] Composition index parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com