Oil refining wastewater oil stain separation device utilizing air flotation method

A technology for separation of oil refining wastewater and oil pollution, applied in flotation water/sewage treatment, grease/oily substance/float removal device, water/sewage treatment, etc. Reasonable structure, strong practicability, and the effect of enhancing the collection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

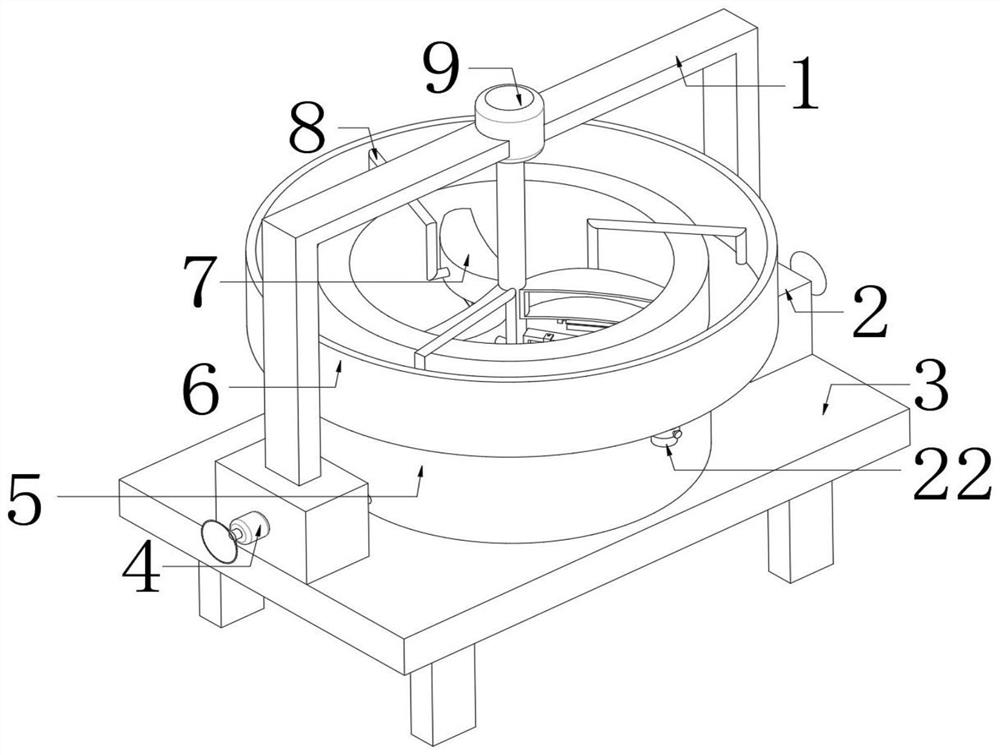

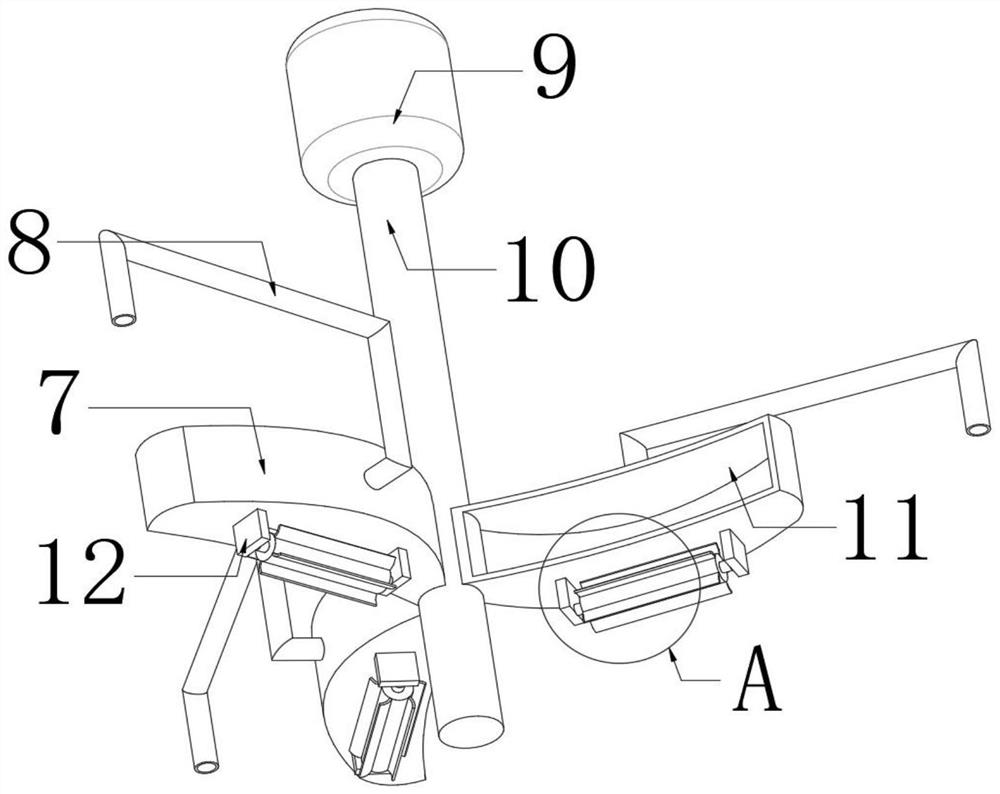

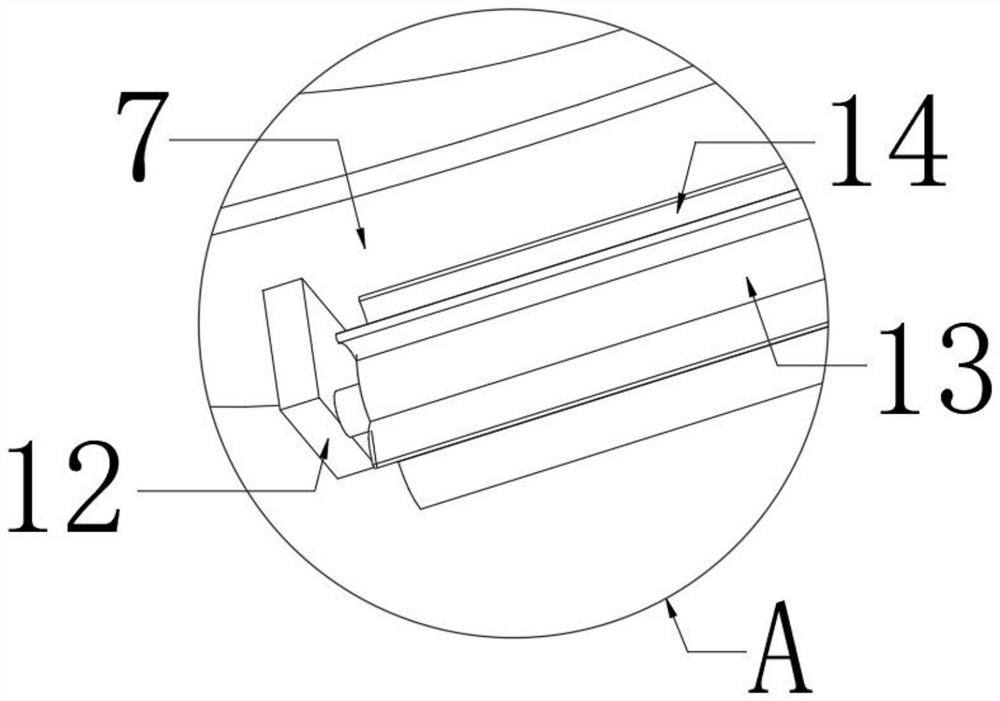

[0028] refer to Figure 1-4 , a kind of refinery wastewater oil separation device utilizing air flotation method, comprising a workbench 3, the top outer wall of the workbench 3 is fixed with a separation cylinder 5 by bolts, the bottom inner wall of the separation cylinder 5 is fixed with an air bag 17 by bolts, and the top of the air bag 17 is The outer wall is provided with air outlets distributed equidistantly, and the inner wall of the air outlet is plugged with an air outlet pipe 19, and both sides of the outer wall of the top of the workbench 3 are provided with an air intake mechanism, and the top outer wall of the air intake mechanism is provided with a cross bar 1, and the cross bar The outer wall of the top of 1 is fixed with a motor 9 by bolts, and the output shaft of the motor 9 is connected with a rotating rod 10 through a coupling. The outer wall is fixed with a mounting plate 12 by bolts, and the outer wall of the mounting plate 12 is connected with a rotating ...

Embodiment 2

[0038] refer to Figure 5 , a kind of refinery wastewater oil separation device utilizing air flotation method, comprising a workbench 3, the top outer wall of the workbench 3 is fixed with a separation cylinder 5 by bolts, the bottom inner wall of the separation cylinder 5 is fixed with an air bag 17 by bolts, and the top of the air bag 17 is The outer wall is provided with air outlets distributed equidistantly, and the inner wall of the air outlet is plugged with an air outlet pipe 19, and both sides of the outer wall of the top of the workbench 3 are provided with an air intake mechanism, and the top outer wall of the air intake mechanism is provided with a cross bar 1, and the cross bar The outer wall of the top of 1 is fixed with a motor 9 by bolts, and the output shaft of the motor 9 is connected with a rotating rod 10 through a coupling. The outer wall is fixed with a mounting plate 12 by bolts, and the outer wall of the mounting plate 12 is connected with a rotating ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com