Electric control valve

An electric control valve and valve core technology, applied in the field of control valve and electric control valve, can solve the problems of large space occupied by the valve body, inconvenient installation, long connection pipeline, etc., and achieve space saving, convenient installation, noise reduction, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

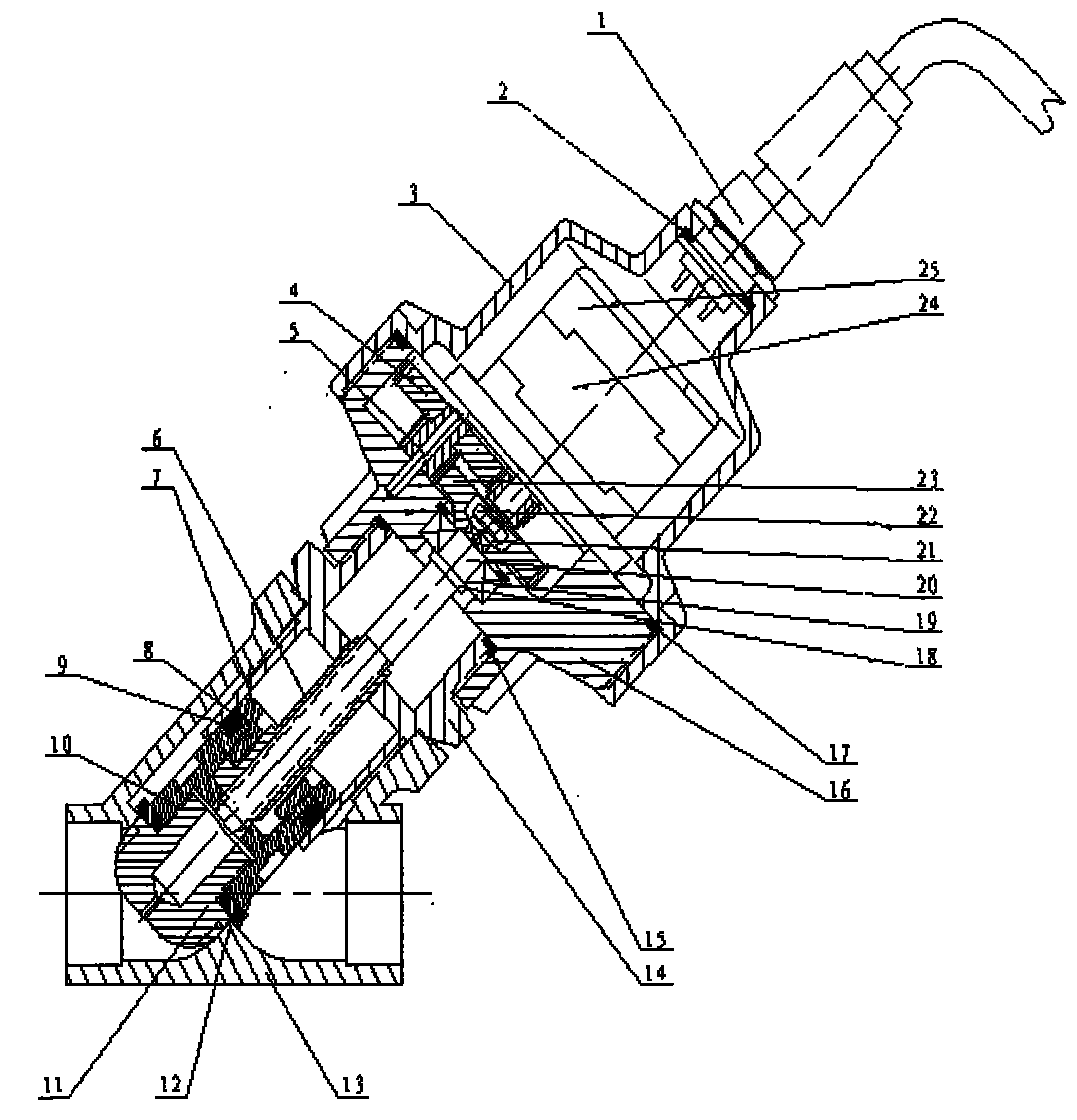

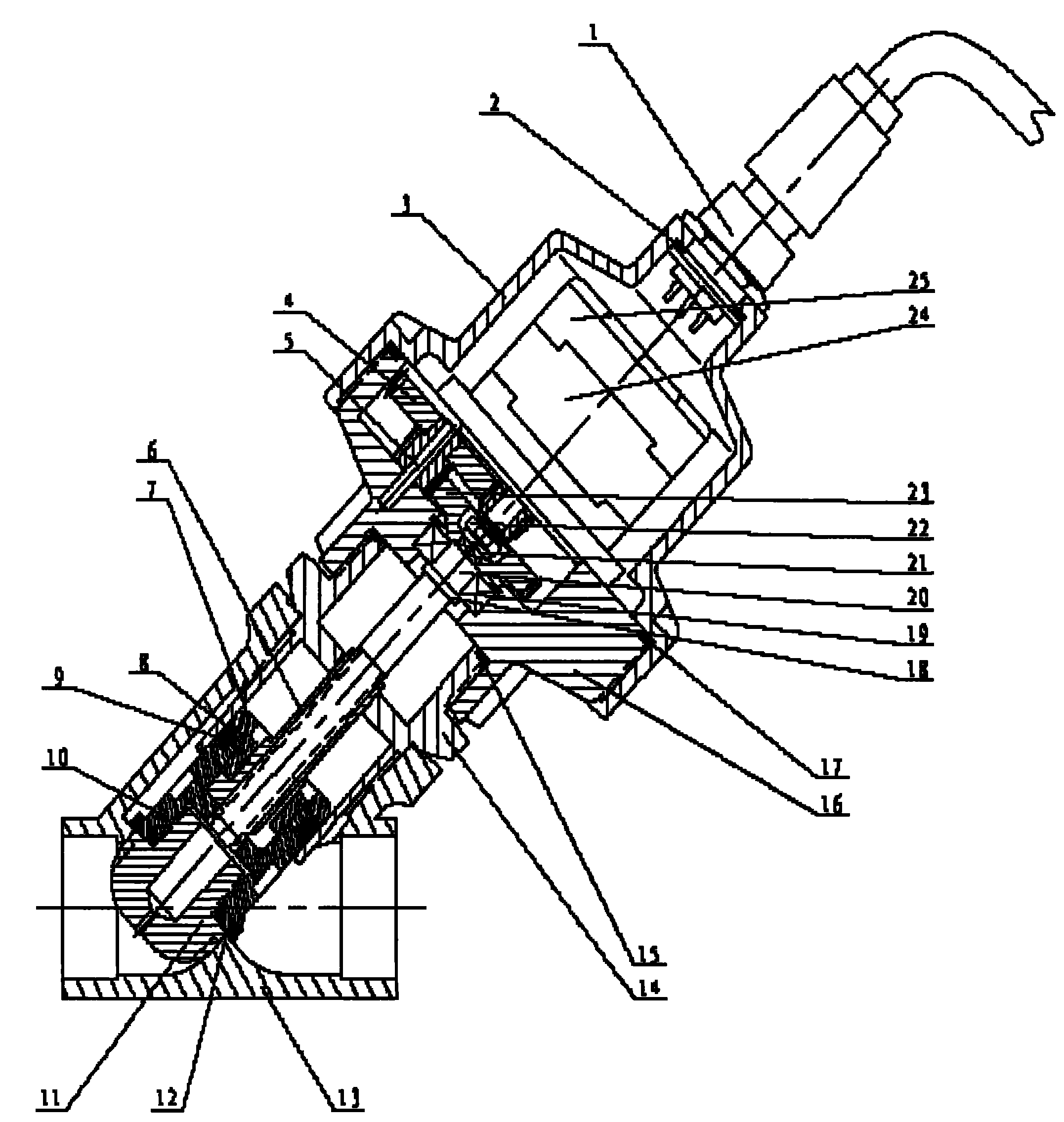

[0015] The electric regulating valve reference of this embodiment figure 1 , including an aviation socket 1 for providing a power signal, the aviation socket 1 is connected to the motor 25, the motor 25 is covered with a motor housing 3 which is sealed and connected to it through an O-ring 2, and the lower end of the motor housing 3 is passed through an O-ring 17 is connected with the motor deceleration seat 16, the motor 25 drives the motor gear 24 to rotate, the motor gear 24 transmits power to the screw gear 23 through the transmission gear 4, the transmission gear 4 is fixed on the motor deceleration seat 16 through the cylindrical pin 5, and the screw gear 23 is connected Drive the screw rod 20 to move, the lower end of the motor deceleration seat 16 is sealed and connected with the valve body seal sleeve 14 through the O-ring 15, the valve body seal sleeve 14 is threaded with the valve body 13, and the outer circumference of the screw rod 20 is threaded with the opening a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com