High-efficiency dense-medium coagulating sedimentation water treatment process

A technology of coagulation, sedimentation and heavy media, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of long residence time and occupying land, and achieve the effect of improving recovery rate, saving civil construction cost and shortening construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

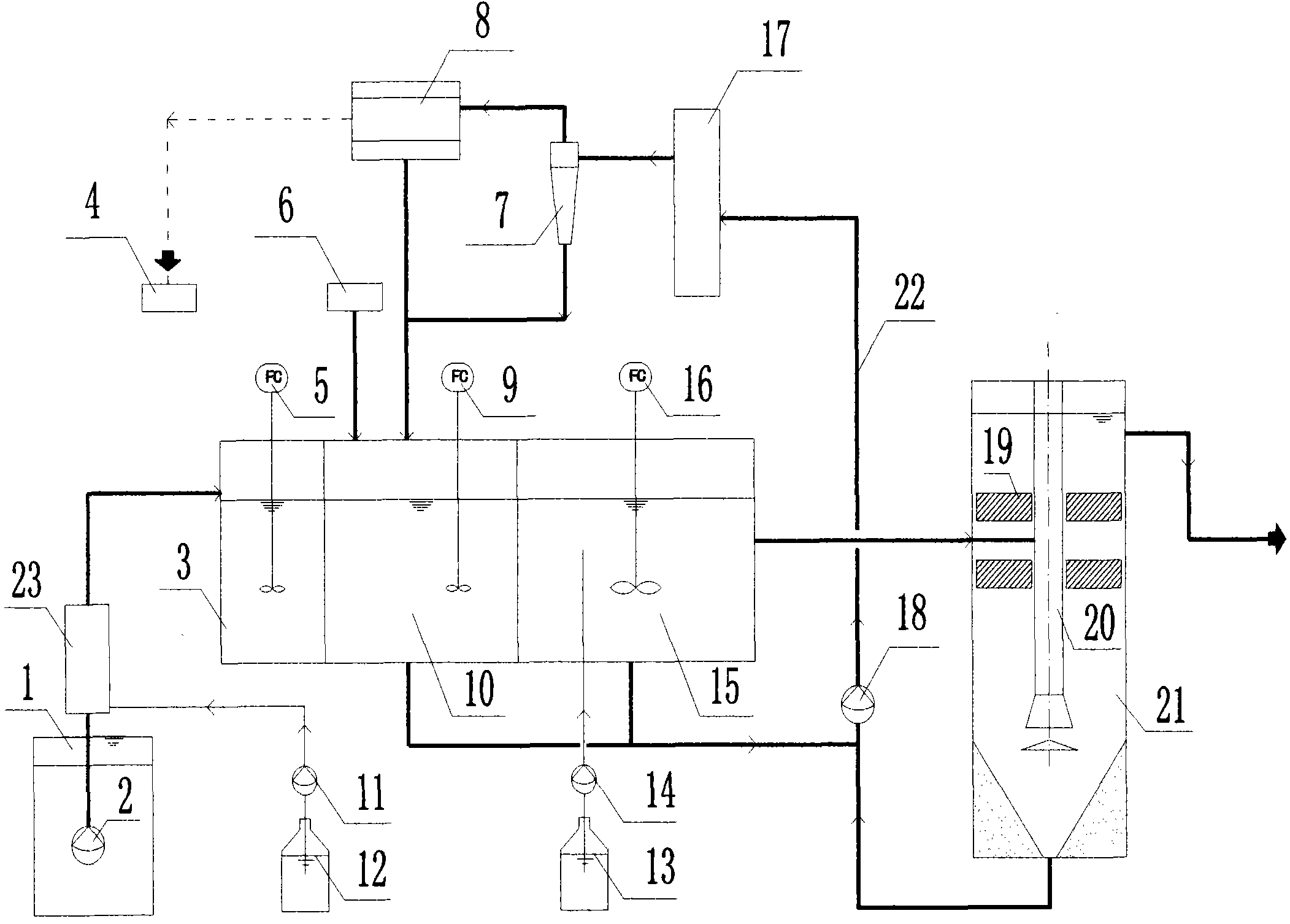

Method used

Image

Examples

Embodiment 1

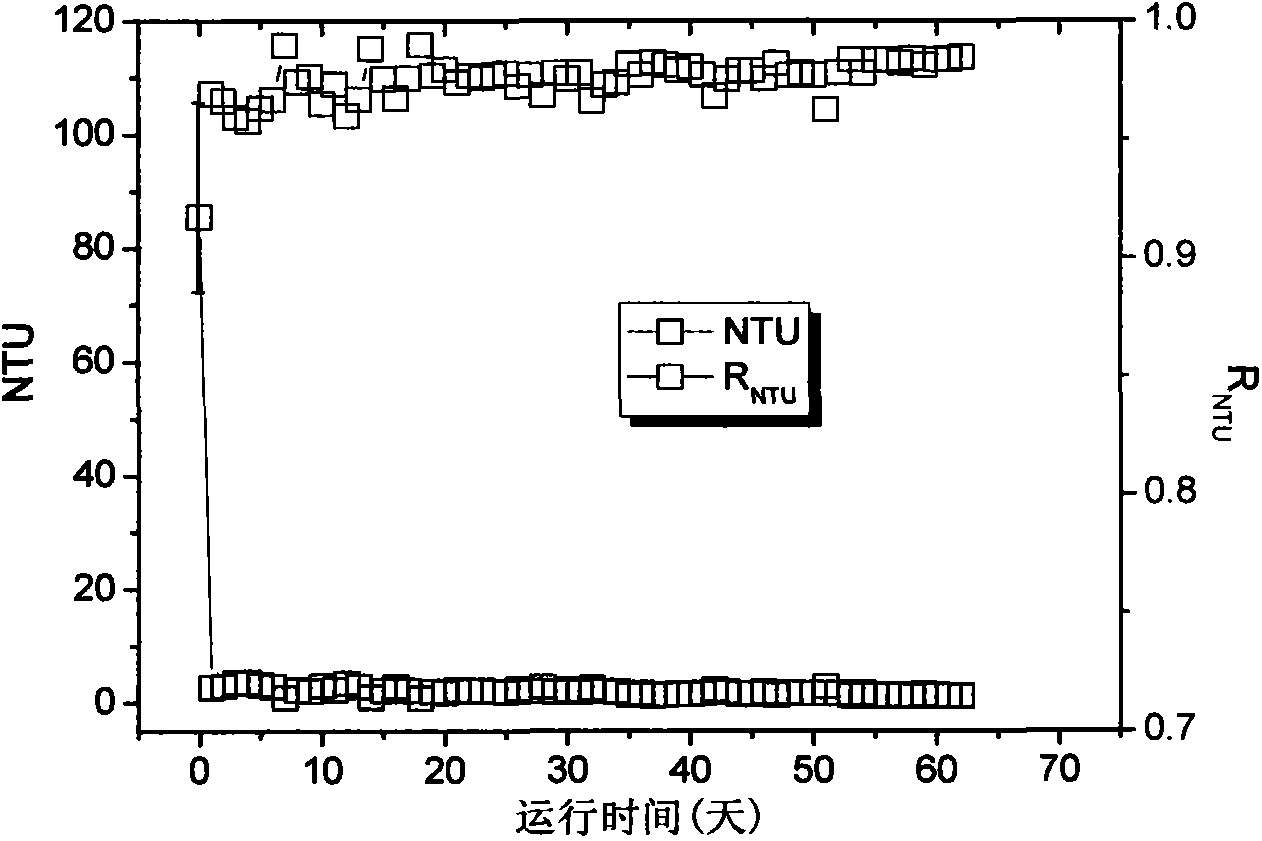

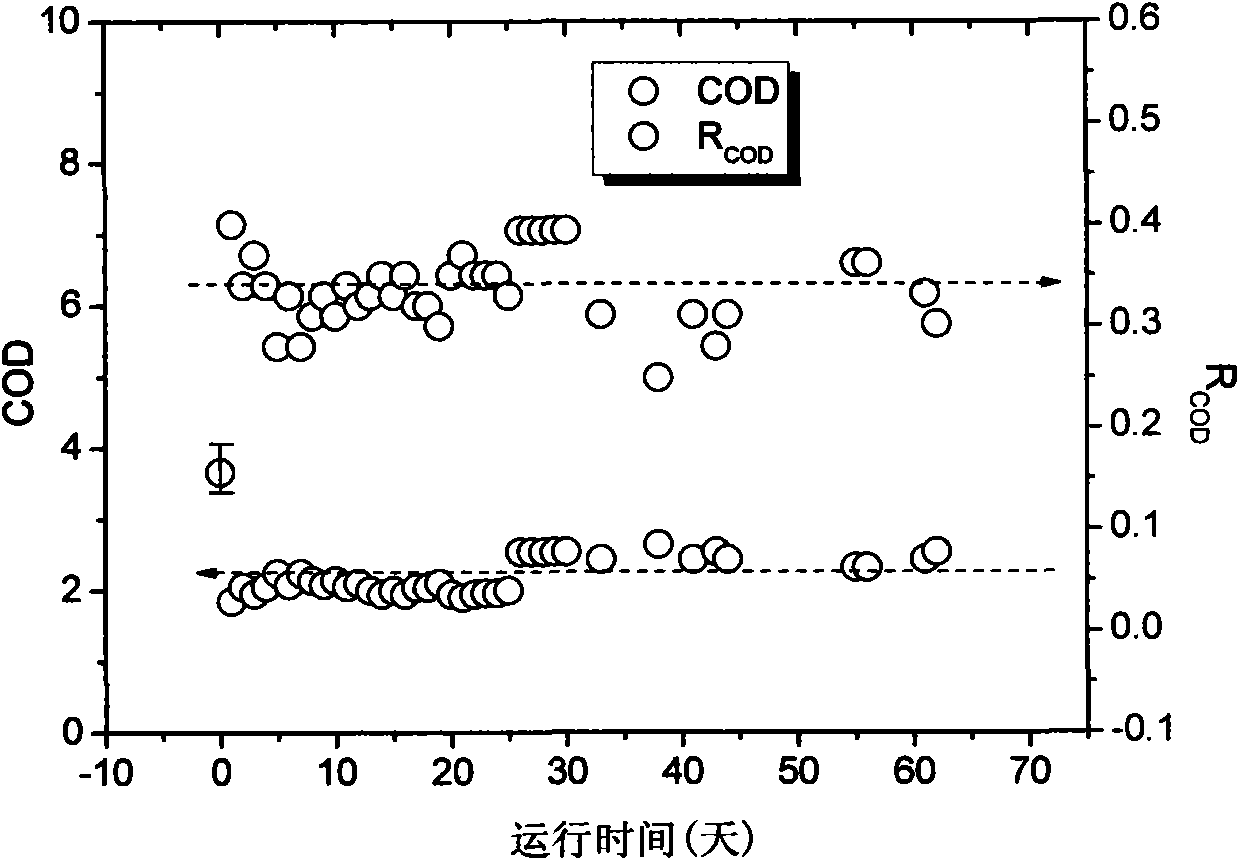

[0021] The raw water samples are taken from the sampling port of a waterworks in the lower reaches of the Yangtze River. The dense medium coagulation process used is as follows: first, polyaluminum chloride (PAC) is added to the raw water to a concentration of 8mg / L (based on a density of 1.24g / ml liquid Polymerized AlCl 3 After mixing evenly, add polyacrylamide (PAM) to a concentration of 0.1mg / L, the amount of heavy medium added during coagulation is 100mg / L, the entire reaction time is 4min, and the water is discharged after 2min of precipitation. In order to investigate the stability of the process, the above process was run for 2 months, and the result of the operation is shown in the figure: During the operation period, the raw water turbidity range is 71-107NTU, COD Mn The range of change is 3.4-4mg / L ( figure 2 with image 3 The effluent turbidity during the whole operation period can be stabilized at <2NTU, the COD can be stabilized at about 2.4mg / L, and the remova...

Embodiment 2

[0025] Table 2: Comparison of turbidity removal performance of different raw water by dense medium coagulation sedimentation process

[0026]

[0027] Remarks: PAC dosage is 8mg / L, PAM dosage is 0.1mg / L, ①-test temperature is 1-2℃, ②-test temperature is 30℃

[0028] In order to investigate the treatment effect of the dense medium coagulation sedimentation process on different water sources: the raw water NTU ranges from 15.9 to 423, and the temperature range is 1°C-30°C (except for the notes, the rest of the treatment temperature is 15-25°C ambient temperature) . As shown in Table 2, the dense-medium coagulation-sedimentation process has a very high impact resistance. In the case of constant dosage, the turbidity of the effluent can be maintained stably no matter in the face of low-temperature low-turbidity or high-turbidity source water. under 2. In addition, the process has no effect on COD MnThe removal rate is kept stable at about 35%, within the range of this experi...

Embodiment 3

[0030] Table 3: Treatment performance comparison of dense medium coagulation sedimentation process / sand flocculation sedimentation process / conventional flocculation sedimentation process

[0031]

[0032] Remarks: PAC dosage is 8mg / L, PAM dosage is 0.1mg / L

[0033] The treatment effects of the density medium separation process, sand addition and conventional flocculation process on the raw water of the Yangtze River are shown in Table 3: under the same operating parameters, the deturbidity and COD removal effect of the dense medium coagulation sedimentation process is significantly better than that of Sand addition and conventional process, which fully demonstrates the advantages of fast and efficient dense medium separation process. Compared with adding sand, the effect of the dense medium powder used in the process of the present invention is better, this is mainly because the density of the dense medium (~4.5g / cm 3 ) than the density of sand (~2.2g / cm 3 ) is larger, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com