Method for automatically clearing syrup in conveying and storing processes

A syrup, automatic technology, applied in the production of sugar, purification of sugar juice, production of sucrose, etc., can solve the problems of increasing the residence time of syrup, unfavorable effect of syrup purity, affecting the recovery rate of scouring, avoiding the loss of sucrose conversion, The method is simple and practical, and the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

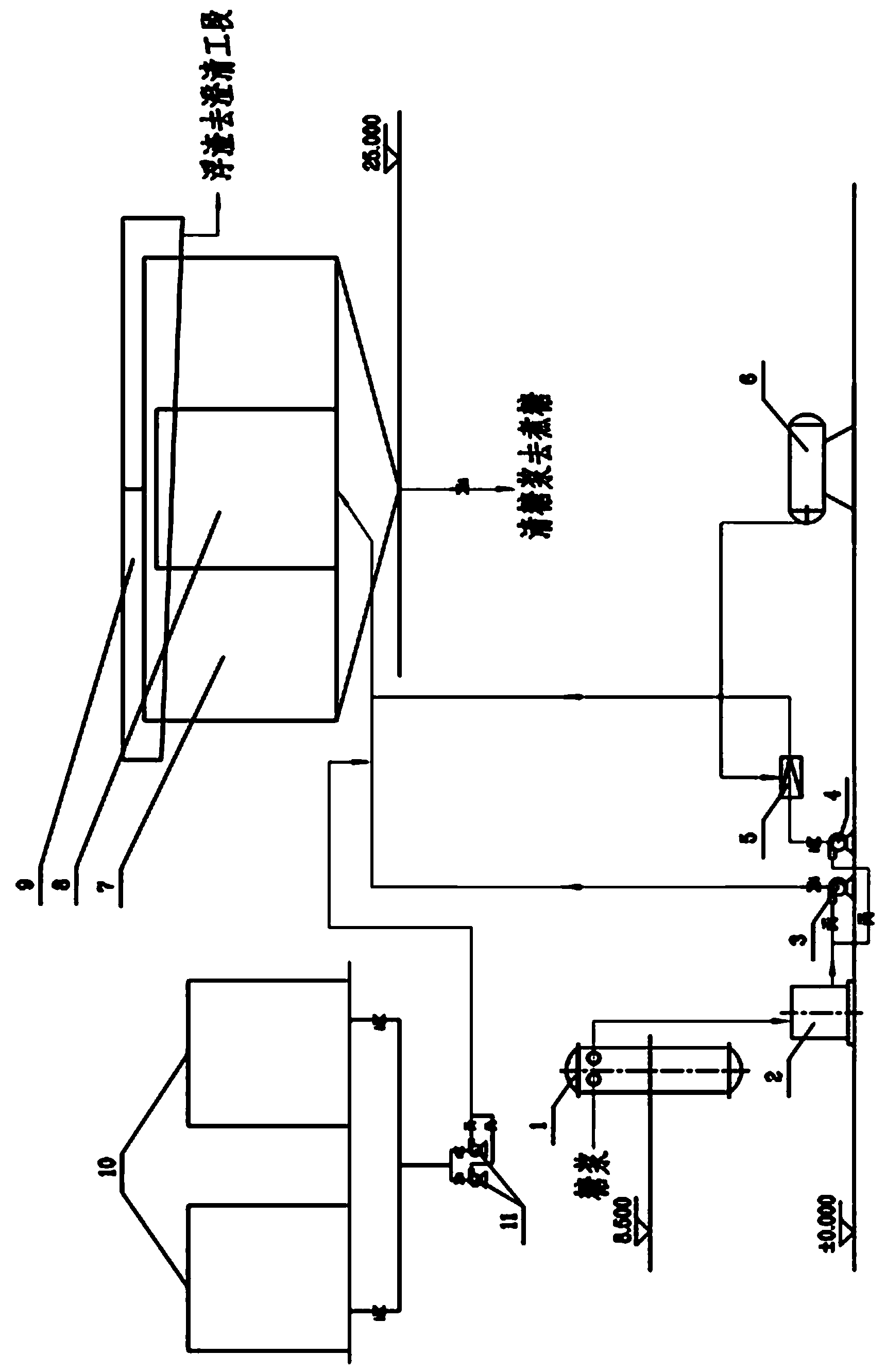

Embodiment 1

[0034] Syrup from the original processing process (the amount of syrup is 50m 3 / h), first heat it to 80~85°C with a tubular heater, heat the steam into a one-effect juice steam, and then discharge it into the syrup tank with a layer of ±0.000, using two syrup delivery pumps (the rated flow rate is 20m 3 / h, 40m 3 / h) Separately transport the syrup to the syrup storage tank of the sugar cooking section. The liquid level difference of the syrup during the conveying process is 25 meters, and the rated flow rate is 20m 3 The outlet pipeline of the / h syrup delivery pump is horizontally installed with an online pipeline suction device. The gas sucked by the suction device is provided by an air compressor, and the rated flow rate is 40m 3 Add polymer flocculant to the delivery pipeline of the syrup delivery pump of / h, the addition amount is 6ppm (for the total syrup solid solution), the syrup storage tank is placed on the top floor of the sugar cooking building, and its shape is ...

Embodiment 2

[0037] Syrup from the original processing process (the amount of syrup is 90m 3 / h), first use a plate heater to heat it to 80~85°C, the heating steam is the second-effect juice vapor, and then discharge it into the syrup tank with a layer of ±0.000, using two pumps (the rated flow rate is 35m 3 / h, 70m 3 / h) respectively send the syrup to the syrup storage tank in the sugar cooking section. 3 The outlet pipeline of the / h syrup delivery pump is horizontally installed with an online pipeline suction device. The gas sucked by the suction device is provided by an air compressor, and the rated flow rate is 70m 3 Add polymer flocculant to the delivery pipeline of the / h syrup delivery pump, the addition amount is 8ppm (total syrup solid solution), the syrup storage tank is placed on the top floor of the sugar cooking building, and its shape is made into a cone with a central inner cylinder type.

[0038] The polymer flocculant is composed of chitosan and shaving nan bark in a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com