Siphon type full automatic aeration biologicall filtering chamber

A biological aerated filter, fully automatic technology, applied in the direction of sustainable biological treatment, aerobic process treatment, etc., can solve the problem of increasing equipment investment, equipment maintenance and operating electricity costs, large volume of backwashing pool, increasing difficulty in operation and management, etc. problems, to achieve the effect of saving equipment investment and operating costs, less maintenance workload, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

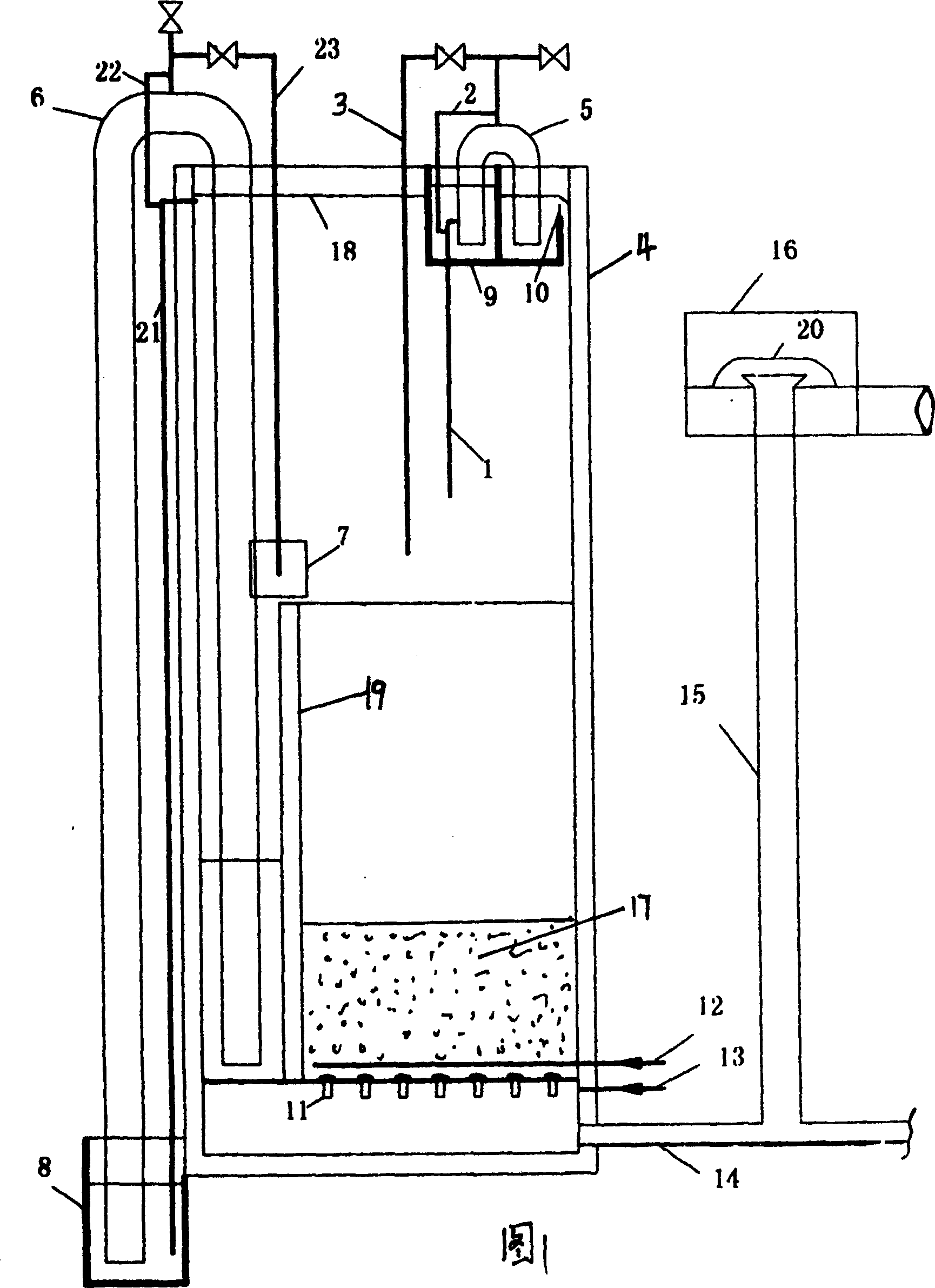

[0008] As shown in Figure 1, the present invention includes water inlet siphon 5, drainage siphon 6, timing water tank 7, water sealing well 8, water inlet canal 9, water outlet weir 10, outlet tank 16, outlet pipe 14, and is characterized in that aerated organisms The filter tank 4 is provided with a filter tank 19, a water inlet channel 9, an outlet weir 10, and a timing water tank 7. The bottom of the biological aerated filter tank 4 is connected with an outlet pipe 14, and the outlet pipe connects several lattice biological aerated filters with each other. Connect the water outlet tank 16, the biological aerated filter 4 is connected to the water sealing well 8, the drainage siphon 6 is connected to the water sealing well 8 and the biological aerated filter 4, and the water inlet siphon 5 is connected to the water inlet channel 9 and the water outlet weir 10. Connect the water inlet auxiliary siphon pipe 1, the water inlet suction pipe 2 and the water inlet siphon destructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com