Outer circulation vertical roller mill

An external circulation and roller-type technology, which is applied in grain processing and other directions, can solve problems such as material collapse, instability, and large gas resistance, and achieve the effects of saving civil engineering costs, facilitating clean production, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

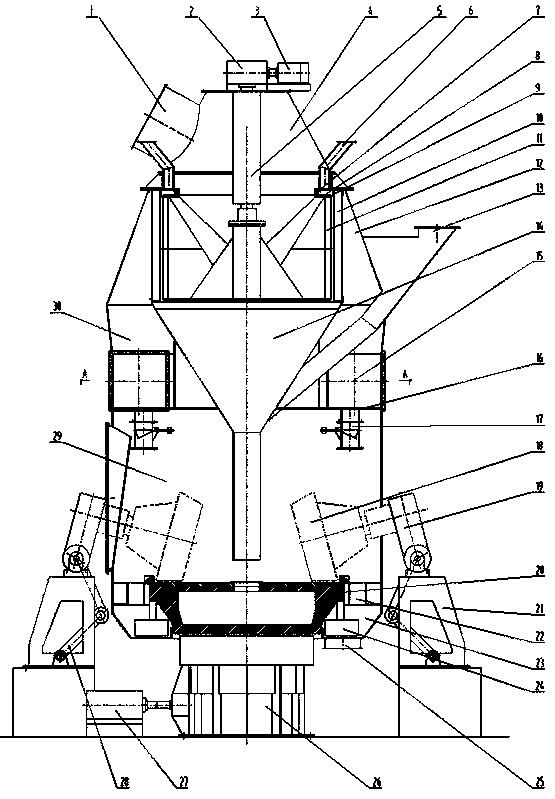

[0024] Such as figure 1 The described vertical roller mill with external circulation includes a mill shell, in which a grinding disc 20 and a grinding roller 18 are arranged, and a powder classifier is arranged on the upper part of the mill shell, and the described The grinding disc 20 is installed on the reducer 26, and the reducer 26 is powered by the main motor 27. The grinding rollers 18 are arranged on the axle seat bracket 21 through the rocker arm 19, and are evenly distributed around the periphery of the mill shell. The rocker arm 19 is also connected with the hydraulic oil cylinder 28 .

[0025] An annular partition plate 16 is arranged at the middle and upper part of the mill shell to divide the mill shell into a grinding cylinder 29 and a powder selection cylinder 30 , and an air lock flap valve 17 is installed under the partition plate 16 . A powder separator is arranged in the powder selection cylinder 30, and the outlet of the powder selection coarse powder ash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com