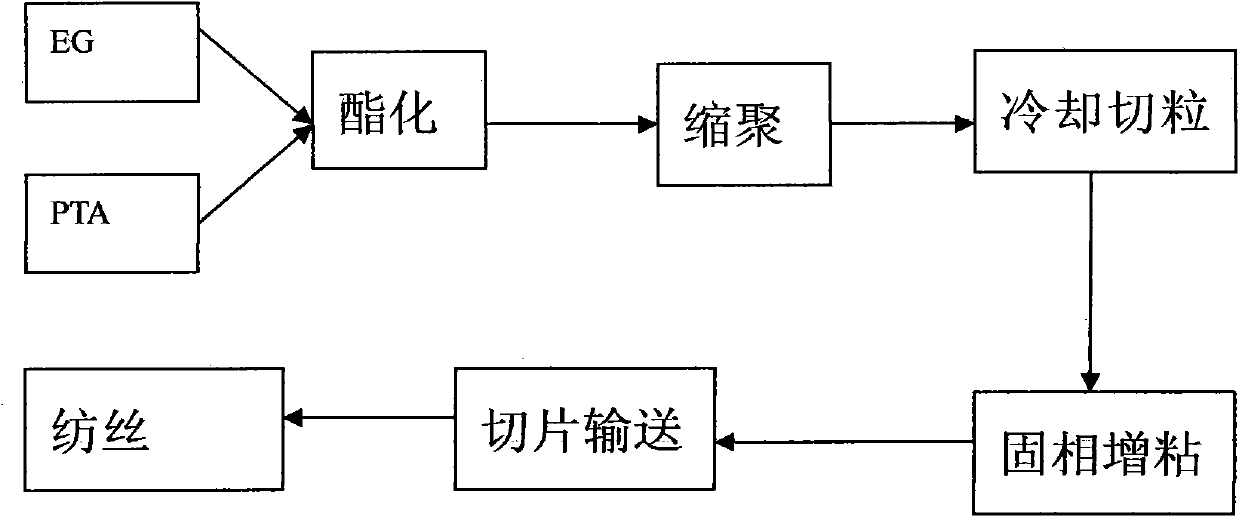

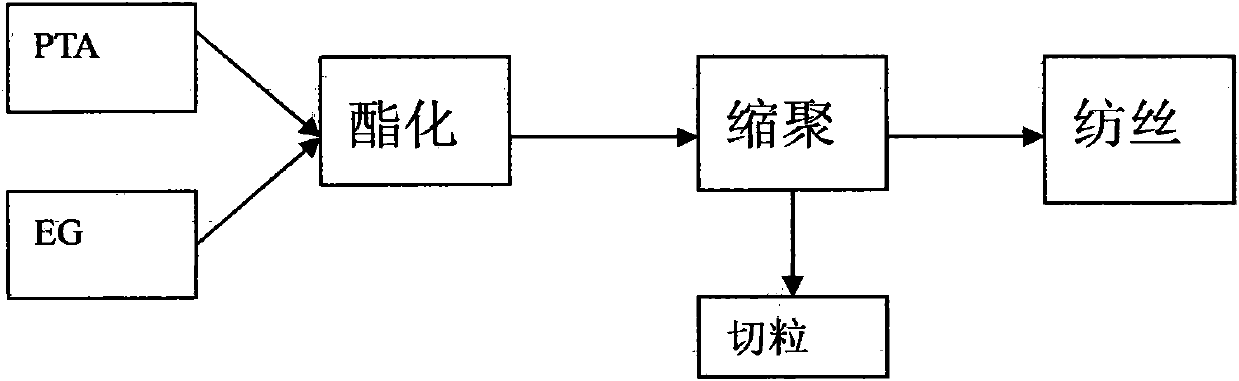

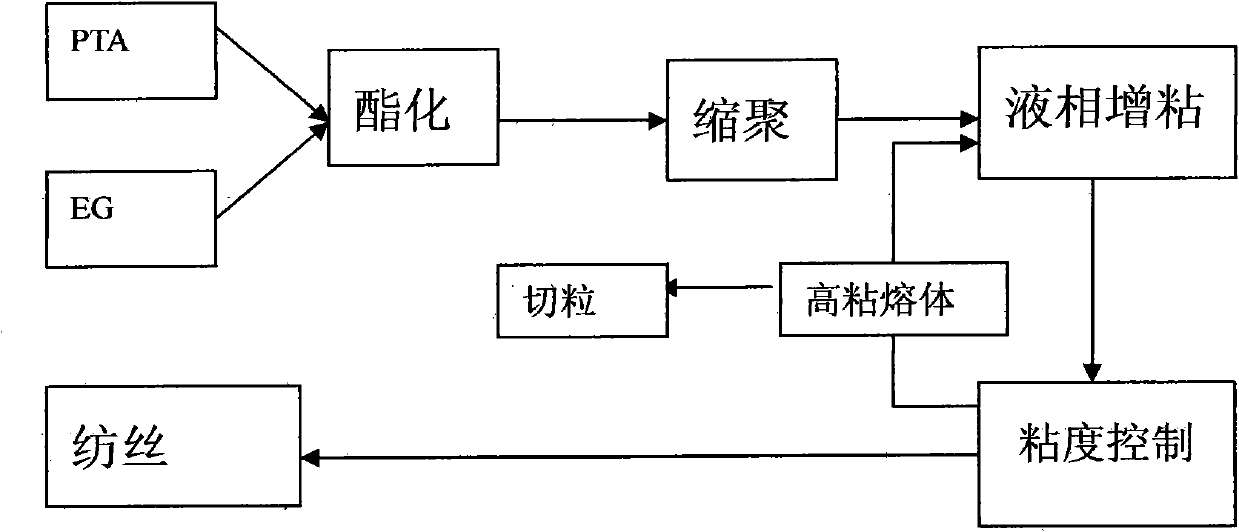

Production process for directly-spun terylene industrial filament of liquid-phase tackifying fusant

A liquid-phase viscosity-increasing and melt-direct spinning technology, applied in the field of spinning, can solve problems such as increased energy consumption and unstable product quality, and achieve the effects of reducing investment costs, saving costs, and solving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: Production of high-strength polyester industrial yarn

[0048]1. Esterification: Put ethylene glycol and phthalic acid in a molar ratio of 1 to 1.3, put in catalyst, trimethyl phosphate, and electrostatic adsorbent to mix into a slurry, and carry out esterification reaction at a temperature of 230 to 260°C to obtain Ethylene terephthalate melt BHET;

[0049] 2. Polycondensation: Pre-condensation reaction is carried out at a temperature of 230-290 ° C and a pressure of 50-1000 Pa for 1.5-2 hours, and then the final polycondensation reaction is below 60 Pa for 60-100 minutes. The melt viscosity measured by a viscometer is 0.63-0.66dl Discharge at / g;

[0050] 3. Liquid phase thickening: Put the above melt in a vertical reactor for liquid phase thickening, the melt enters from the top for distribution, and the film is naturally formed by gravity, the vacuum degree in the kettle is 50Pa-120Pa, and the temperature is 280°C-300°C , The residence time of the me...

Embodiment 2

[0052] Embodiment 2: Production of low-shrinkage polyester industrial filament

[0053] 1. Esterification: Put ethylene glycol and phthalic acid in a molar ratio of 1 to 1.3, put in catalyst, trimethyl phosphate, and electrostatic adsorbent to mix into a slurry, and carry out esterification reaction at a temperature of 230 to 260°C to obtain Ethylene terephthalate melt BHET;

[0054] 2. Polycondensation: Pre-condensation reaction is carried out at a temperature of 230-290 ° C and a pressure of 50-1000 Pa for 1.5-2 hours, and then the final polycondensation reaction is below 60 Pa for 60-100 minutes. The melt viscosity measured by a viscometer is 0.63-0.66dl Discharge at / g;

[0055] 3. Liquid phase thickening: Put the above melt in a vertical reactor for liquid phase thickening, the melt enters from the top for distribution, and the film is naturally formed by gravity, the vacuum degree in the kettle is 50Pa-120Pa, and the temperature is 280°C-300°C , The residence time of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com