System and method for disposing large blast capacity low concentration mixed harmful gas

A harmful gas and concentration technology, applied in chemical instruments and methods, combustion methods, gas treatment, etc., can solve the problems of single type of treatment and inability to purify multiple types of harmful gases at the same time, so as to ensure continuous operation and avoid secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

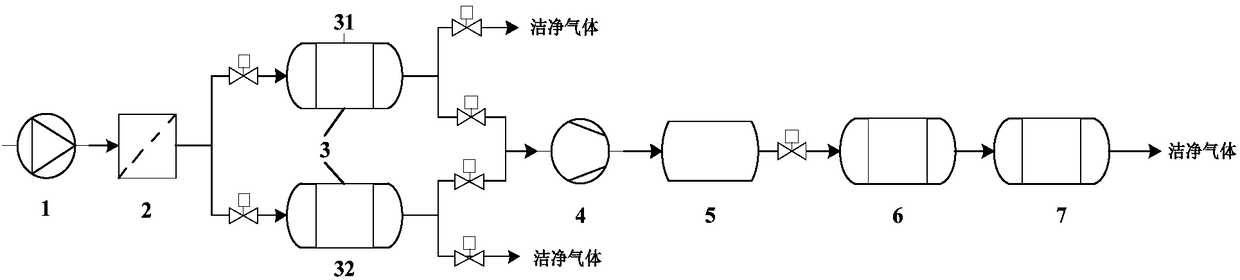

[0081] This embodiment provides a system for processing large air volume and low concentration mixed harmful gas. The schematic diagram of the device connection is as follows figure 1 As shown, the system includes a purification regeneration adsorption device 3, a catalytic combustion purification device 6 and a terminal purification adsorption device 7 connected in sequence, the outlet of the purification regeneration adsorption device 3 is divided into two branches, one is connected to the exhaust port, One is connected with the inlet of the catalytic combustion purification device 6 .

[0082] Wherein, the purification regeneration adsorption device 3 includes a first purification regeneration adsorption device 31 and a second purification regeneration adsorption device 32 arranged in parallel, and a heating device is installed in the purification regeneration adsorption device 3 .

[0083] The system also includes a filter device 2 , the outlet of the filter device 2 is co...

Embodiment 2

[0088] This embodiment provides a system for treating mixed harmful gases with large air volume and low concentration. The system refers to the system in Embodiment 1, and the only difference is that there is only one purification and regeneration adsorption device 3 .

Embodiment 3

[0090] This embodiment provides a method for dealing with large air volume and low concentration mixed harmful gases, the mixed harmful gases include ammonia, formaldehyde, hydrogen sulfide and n-heptane, the flow velocity is 0.4m / s, and the concentration of harmful gases is ammonia 5ppm, formaldehyde 0.29ppm, hydrogen sulfide 0.13ppm and n-heptane 4.5ppm.

[0091] Described method adopts the system in embodiment 1 to carry out, and described method comprises the following steps:

[0092] (a) After the above-mentioned mixed harmful gas is first filtered, then adsorbed with a uniformly mixed molecular sieve adsorbent, the molecular sieves include mordenite molecular sieves, ZSM-5 molecular sieves and alumina molecular sieves, and their corresponding mass ratios are 1 :8:12, after the adsorption is saturated, the temperature is 125°C and the vacuum degree is -0.07MPa, and the temperature is 125°C and the vacuum degree is -0.07MPa. Alternately, get concentrated harmful gas;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com