A cabin air purification device

An air purification device and purification device technology, applied in the field of air purification, can solve the problems of short service life, high personnel density, and high cost of use of air purifiers, and achieve the effect of restoring absorption and purification capacity, good purification effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

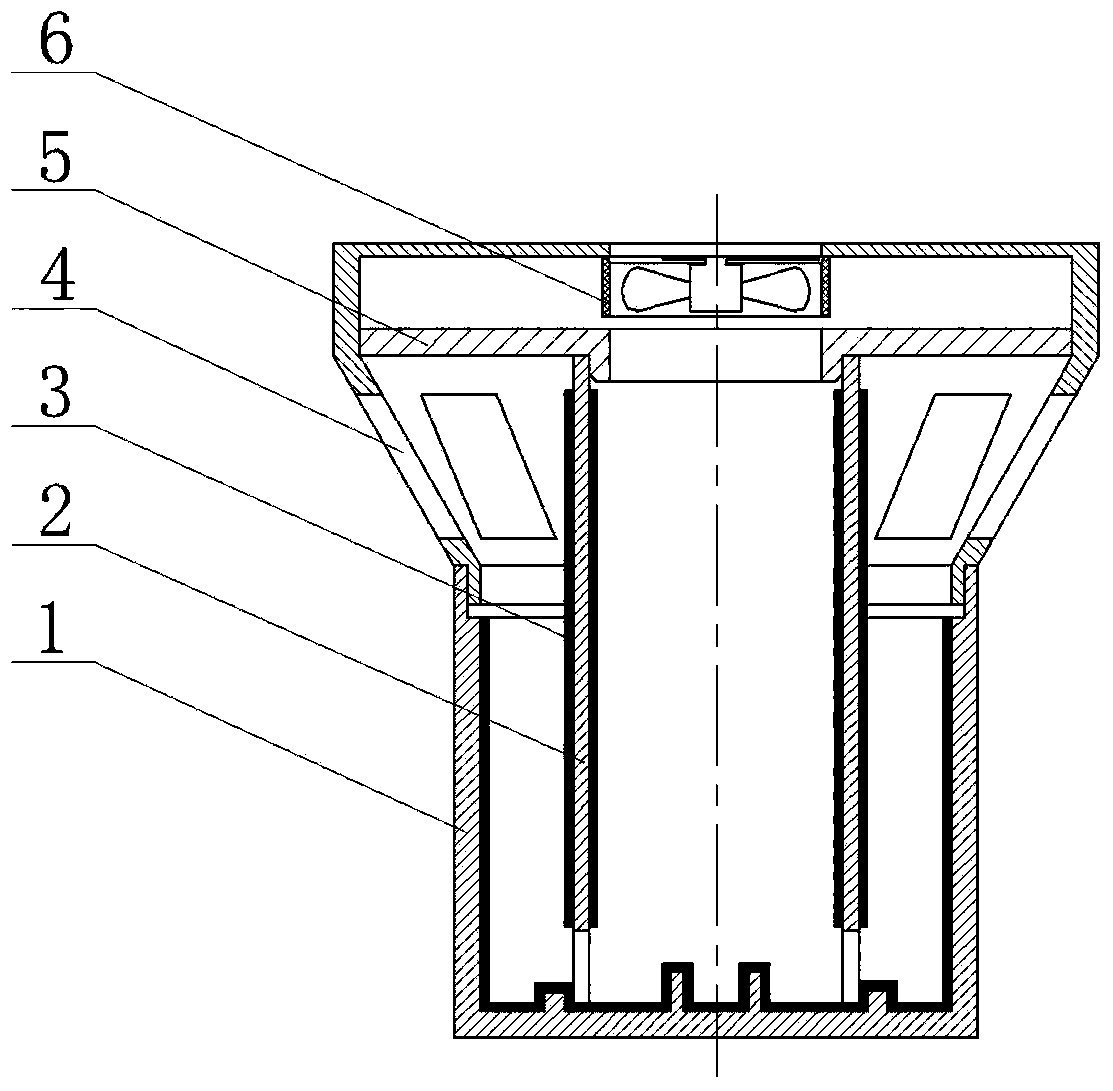

[0046] An air purification device in a cabin, comprising a container 1, a cylindrical carrier 2, a casing 4, a partition 5, a fan 6 and a soft gel 3, and the soft gel 3 is evenly coated on both sides of the side wall of the cylindrical carrier , the inner wall of the container, the bottom of the container or two or more of the concentric ring platforms, such as figure 1 shown.

[0047] Described container 1 is a cylindrical flat-bottomed open container (inner diameter 100mm, high 120mm); Container 1 bottom is provided with 1 concentric ring platform, and the height of concentric ring platform is 10 millimeters, and width is 1 millimeter. A cylindrical carrier 2 is vertically placed inside the container 1. The cylindrical carrier 2 is a hollow cylinder (inner diameter 65mm, height 180mm) with both ends open. Hole, the bottom of the cylinder wall is provided with 8 strip-shaped slots vertically along the axial direction as ventilation holes, and the ventilation holes connect th...

Embodiment 2

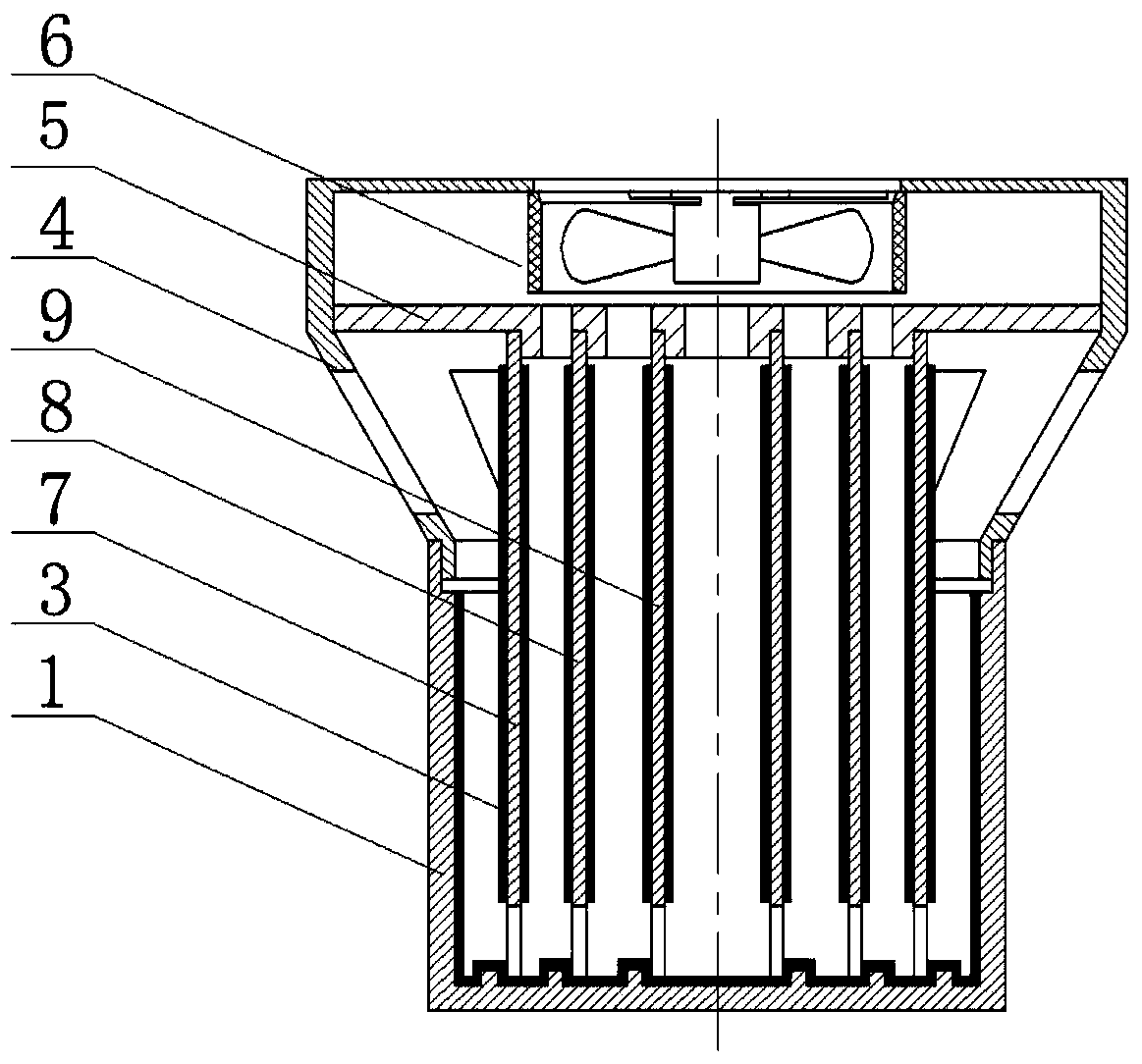

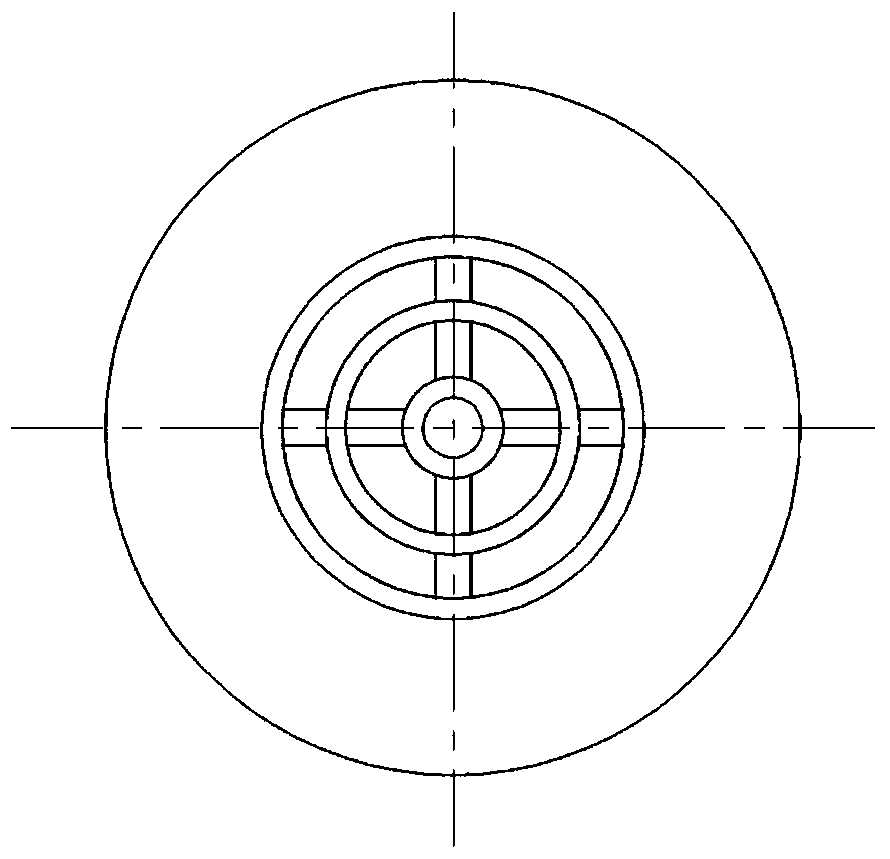

[0051] Compared with the device described in Example 1, the difference is that the inner diameter of the container 1 is 400mm, and there are 3 ring-shaped clamping stations at the bottom, and 3 cylindrical carriers with different diameters are coaxially placed in the container 1 from the center to the outside. ;like figure 2 shown. Wherein, the lower end of the shell 4 is in the shape of a rounded frustum, and an air outlet is provided on the side of the rounded frustum, the diameter of the upper cone is 500 mm, and the lower cone closely matches the opening of the container 1 . In this device, the partition plate 5 is provided with three annular slots, respectively fixing the corresponding cylindrical carrier, and fixing it with a cross-shaped beam. The cross section of the partition plate is as follows: image 3 shown.

Embodiment 3

[0053] Compared with the device described in Embodiment 1, the difference lies in that the lower end of the shell 4 is cylindrical, and the diameter of the upper end is consistent. The side of the cylindrical carrier 2 is provided with dense small holes for easy attachment of the soft gel. There are 2 concentric ring platforms at the bottom of the container 1, and the device is as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com