Purification method of fluorescent protein

A technology of fluorescent protein and purification method, which is applied to the preparation method of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problems of environmental pollution, complex process, low purification factor of fluorescent protein, etc., and achieve simple and efficient purification method, high purification low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1. Fluorescent protein expression vector construction

[0052] With EGFP-F (5'-cggcagc catatg gtgagcaagggcgagg-3', the underline is the Nde I restriction site) is the upstream primer, EGFP-R (5'-ccg ctcgag ttagtggtgatggtgatggtg-3', the underline is the Xho I restriction site) as the downstream primer, and the commercially available plasmid pEGFP-N1 was used as the template to amplify the EGFP gene by PCR. After recovery, the PCR product was digested with Nde I and XhoI, and the double digested product was recovered and connected to the commercialized plasmid pET-24a that had undergone the same double digestion to obtain the pET-24a-EGFP vector, which is a fluorescent protein Expression vector of EGFP.

Embodiment 2

[0053] Example 2. Fluorescent protein expression

[0054] The expression vector pET-24a-EGFP was transformed into Escherichia coli BL21 (DE3) competent cells, spread on LB plates (containing 50 mg / L kanamycin), and cultivated overnight in a 37°C incubator.

[0055] Pick a single colony from the overnight cultured LB plate into a 250mL shake flask filled with 50mL LB medium, place it on a constant temperature shaker at 37°C at 200rpm / min, and cultivate it for 20h as a seed solution.

[0056] Inoculate the cultivated seed solution into 1000mL shake flasks with 100mL self-induction medium, inoculate 8 bottles altogether, the inoculum size of each bottle is 5% (v / v), place in a constant temperature shaker, 200rpm / min, After incubating at 37°C for 3h, transfer to 25°C for 20h. Among them, the formula of self-induction medium is: lactose 2g / L; peptone 10g / L; yeast powder 5g / L; NaCl 10g / L; glycerin 8ml / L.

[0057] Collect all the culture fluid, centrifuge and remove the supernatant...

Embodiment 3

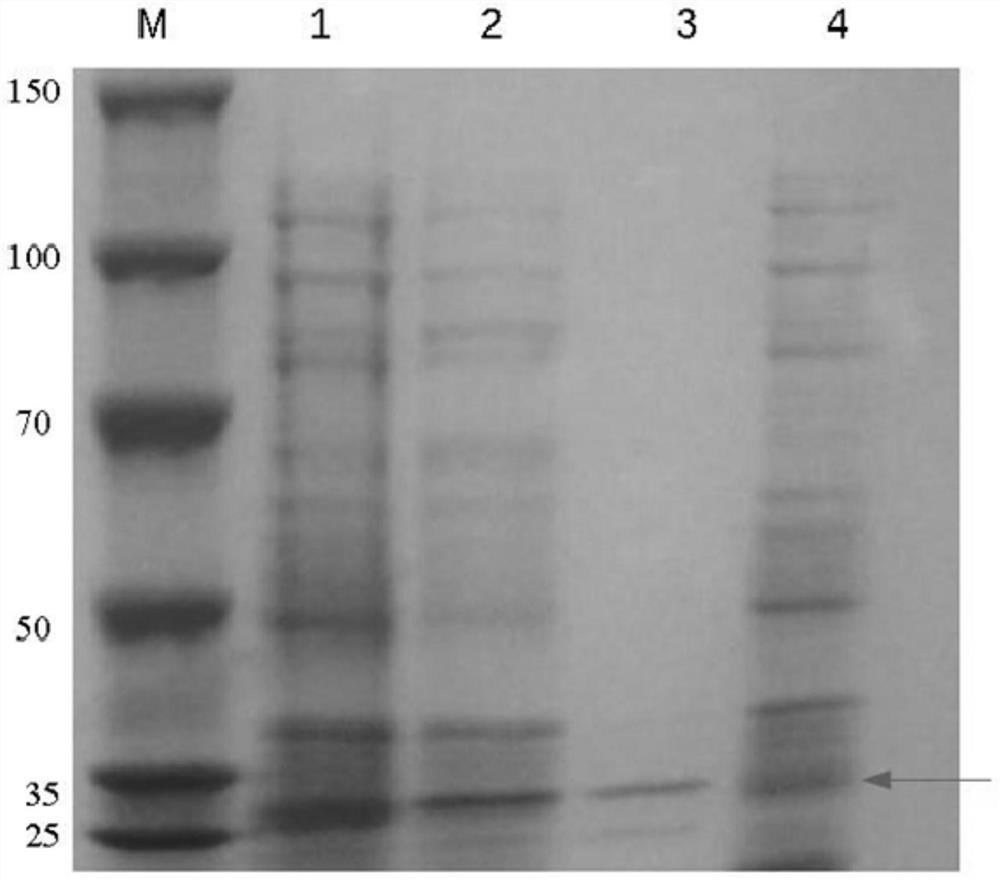

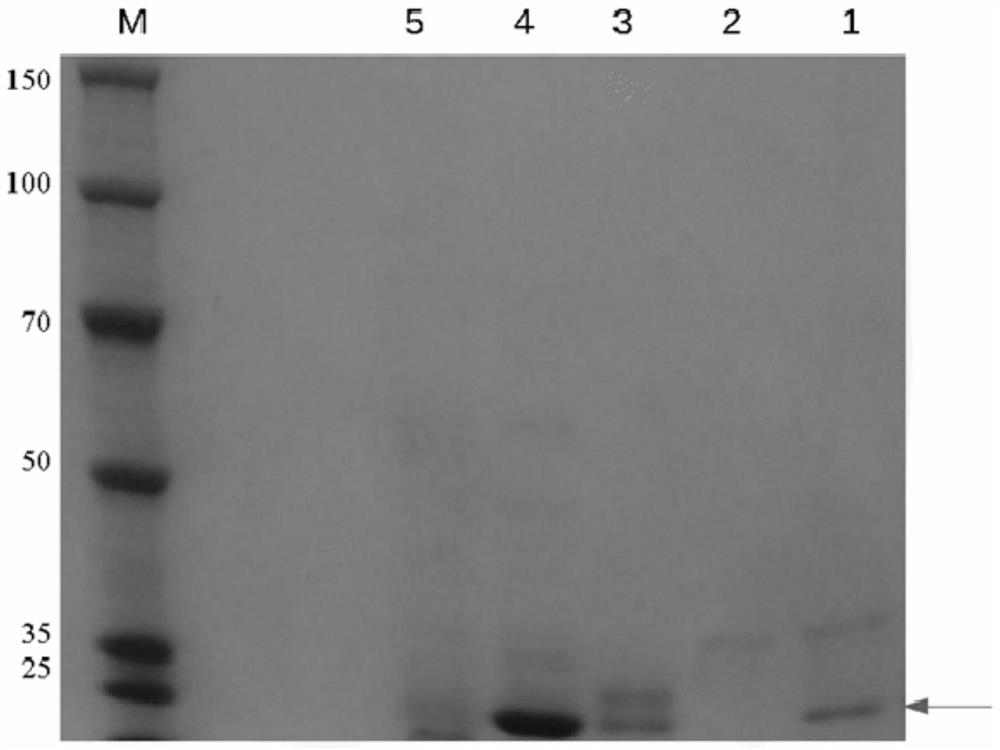

[0058] Example 3. Fluorescent protein purification

[0059] Add 100 mL of Tris (50 mmol / L, pH 8.0) buffer solution to the centrifuge bottle where the bacteria were collected to suspend the bacteria, and break the cells with a high-pressure homogenizer until the suspension becomes clear. Place the bacteriostasis solution in a water-bath shaker at 65°C, and incubate at 100rpm / min for 15min. After heat treatment, centrifuge (8000rpm / min, 10min), take the supernatant, and discard the precipitate.

[0060] Add 2mol / L ZnCl to the supernatant 2 Mix the solution until its final concentration is 20mmol / L, and a large amount of protein precipitation can be observed, centrifuge again (8000rpm / min, 10min), take the precipitate, and discard the supernatant.

[0061] Add 100mL Tris (50mmol / L, pH 8.0) buffer solution to the precipitate to fully suspend the precipitate, centrifuge (8000rpm / min, 10min), and take the supernatant. Dissolve the precipitate with 100mL EDTA (5mmol / L, pH8.0) solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com