Method for preparing porous difunctional adsorption material

An adsorption material, dual-function technology, applied in selective adsorption, chemical instruments and methods, ion exchange, etc., can solve problems such as single performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

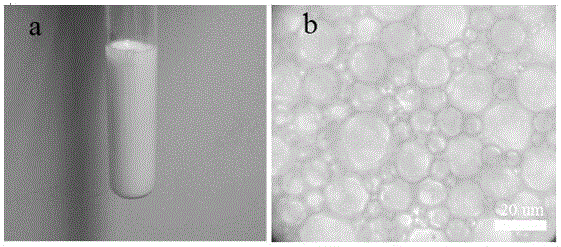

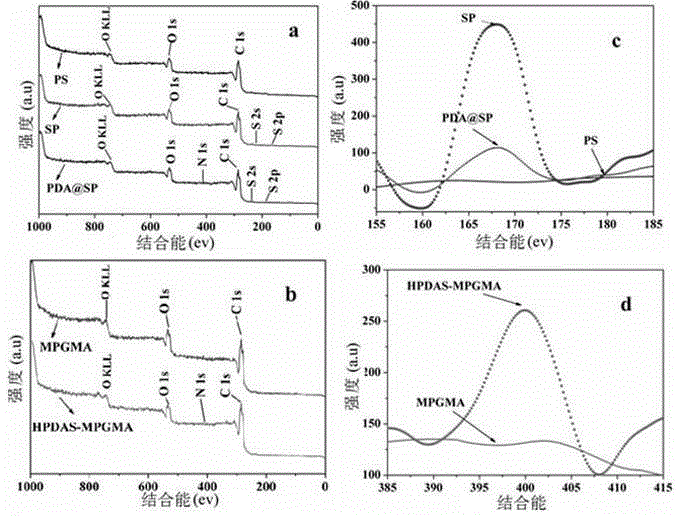

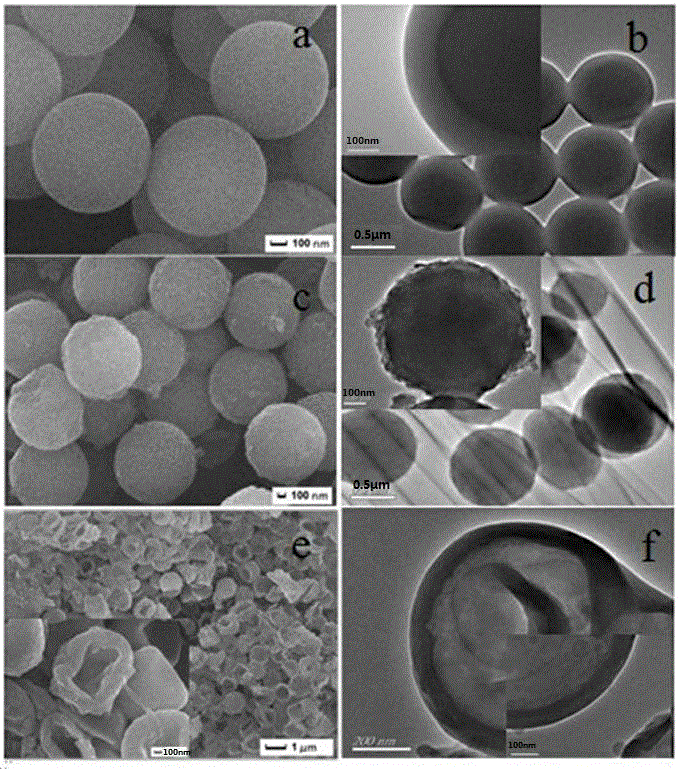

[0041] 1. Preparation of hollow dopamine-adhered macroporous materials

[0042] (1) Preparation of dopamine microspheres:

[0043] Dissolve 0.7g of polyvinylpyrrolidone powder in a mixed solution of 50mL of absolute ethanol and 10mL of deionized water, disperse it evenly by ultrasonication for 10 minutes, put it into a three-necked flask equipped with nitrogen, a stirrer, and a condenser, and pass nitrogen Half an hour, after fully removing the dissolved oxygen in it. Then, 5 mL of styrene monomer dissolved in 0.04 g of azobisisobutyronitrile was added under mechanical stirring, and then reacted in a water bath at 70° C. for 24 hours. After the reaction was complete, polystyrene microspheres were collected by centrifugation. The polystyrene microspheres were washed several times with a 1:3 solution of absolute ethanol and deionized water, and the prepared polystyrene microspheres were vacuum-dried overnight at 40 °C.

[0044] Add 1.0 g of dried polystyrene microspheres into...

Embodiment 2

[0064] 1. Preparation of hollow dopamine-adhered macroporous materials

[0065] (1) Preparation of dopamine microspheres:

[0066] Dissolve 0.7g of polyvinylpyrrolidone powder in a mixed solution of 50mL of absolute ethanol and 10mL of deionized water, disperse it evenly by ultrasonication for 10 minutes, put it into a three-necked flask equipped with nitrogen, a stirrer, and a condenser, and then pass nitrogen half an hour. After fully removing the dissolved oxygen therein, add 5 mL of styrene monomer dissolved with 0.04 g of azobisisobutyronitrile under mechanical stirring, and then react in a water bath at 70°C for 24 hours. After the reaction is complete, centrifuge to collect polystyrene micro ball. The polystyrene microspheres were washed several times with a 1:3 solution of absolute ethanol and deionized water, and the prepared polystyrene microspheres were vacuum-dried overnight at 40 °C.

[0067] Add 1.0 g of dried polystyrene microspheres into 35 mL of 98% concen...

Embodiment 3

[0082] 1. Preparation of hollow dopamine-adhered macroporous materials

[0083] (1) Preparation of dopamine microspheres:

[0084] Dissolve 0.7g of polyvinylpyrrolidone powder in a mixed solution of 50mL of absolute ethanol and 10mL of deionized water, disperse it evenly by ultrasonication for 10 minutes, put it into a three-necked flask equipped with nitrogen, a stirrer, and a condenser, and then pass nitrogen half an hour. After fully removing the oxygen dissolved therein, 5 mL of styrene monomer dissolved in 0.04 g of azobisisobutyronitrile was added under mechanical stirring. Finally, react in a water bath at 70° C. for 24 hours, and centrifuge to collect polystyrene microspheres after the reaction is complete. The polystyrene microspheres were washed several times with a 1:3 solution of absolute ethanol and deionized water, and the prepared polystyrene microspheres were vacuum-dried overnight at 40 °C.

[0085] Add 1.0 g of dried polystyrene microspheres to 40 mL of 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com