Method for recycling micro-fine particle class cassiterite

A technology of micro-fine particles and cassiterite, applied in solid separation, flotation, etc., can solve the problems of not reporting the actual composition of JSY-19, failing to achieve high-efficiency utilization of fine-grained cassiterite, and practical limitations in industrial applications, and achieve savings Reagent cost, avoidance of tin recovery, avoidance of significant drop in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

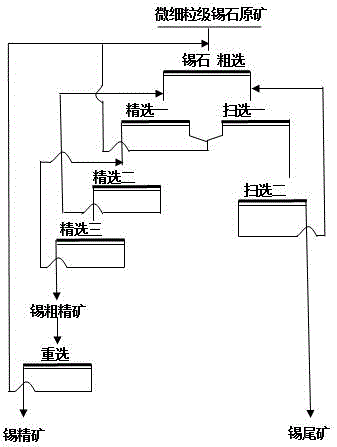

Image

Examples

Embodiment 1

[0031] The tin ore contains 0.39% tin, and the -37μm particle size distribution rate is 71%.

[0032] (1) Mix hydroxylamine hydrochloride, methyl benzoate, sodium hydroxide, and water in a mass ratio of 6:11:3:80, heat to 45°C, stir for 1.5 hours, and cool to room temperature to become drug K.

[0033] (2) Mix agent K, dodecyl sulfosuccinic acid, and styrene phosphonic acid in a mass ratio of 78:9:13, vibrate and stir with an ultrasonic instrument for 50 minutes, and make a combined collector KMC.

[0034](3) Add combined collector KMC 2400g / t to the tin ore slurry with a mass percentage concentration of 25%-30%, add 40g / t of auxiliary collector with commercial code P86, stir for 6min-7min, add pine Alcohol oil 40g-50g / t, after stirring for 3.5min-4.5min, use a flotation machine for roughing for 8min-10min, the rough concentrate ore will be refined for three times to obtain tin coarse concentrate, and the selected tailings will return to the previous Classification: roughing ...

Embodiment 2

[0038] The tin ore contains 0.54% tin, and the -37μm particle size distribution rate is 68%.

[0039] (1) Mix hydroxylamine hydrochloride, methyl benzoate, sodium hydroxide, and water in a mass ratio of 6:11:3:80, heat to 50°C, stir for 2 hours, and cool to room temperature to become drug K.

[0040] (2) Mix agent K, dodecyl sulfosuccinic acid, and styrene phosphonic acid in a mass ratio of 78:9:13, vibrate and stir with an ultrasonic instrument for 70 minutes, and make a combined collector KMC.

[0041] (3) Add combined collector KMC 3000g / t and auxiliary collector 50g / t commercial code P86 to the tin ore slurry with a mass percentage concentration of 30%-35%, stir for 7min-8min, add pine Alcohol oil 50g-60g / t, after stirring for 3min-4min, use a flotation machine for roughing for 10min-11min, rough concentrate ore will be refined for three times to obtain tin coarse concentrate, and the selected tailings will return to the previous stage of separation Separation; the roughi...

Embodiment 3

[0045] The tin ore contains 0.66% tin grade, and the -37μm particle size distribution rate is 65%.

[0046] (1) Mix hydroxylamine hydrochloride, methyl benzoate, sodium hydroxide, and water in a mass ratio of 6:11:3:80, heat to 55°C, stir for 1.8 hours, and cool to room temperature to become drug K.

[0047] (2) Mix agent K, dodecyl sulfosuccinic acid, and styrene phosphonic acid in a mass ratio of 78:9:13, vibrate and stir with an ultrasonic instrument for 1 hour, and make a combined collector KMC.

[0048] (3) Add the combined collector KMC4500g / t to the tin ore pulp with a mass percentage concentration of 31%-34%, add 60g / t of auxiliary collector with commercial code P86, stir for 6.5min-7.5min, add Pine alcohol oil 20g-30g / t, after stirring for 4min-5min, use a flotation machine for roughing for 11min-12min, rough concentrate ore will get tin coarse concentrate after three times of beneficiation, and the beneficiated tailings will return to the previous level Separation: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com