Optimization control apparatus for denitrification carbon source addition in AO process

An optimized control and denitrification technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, water pollutants, etc., can solve the problem of insufficient carbon source dosage, improper carbon source dosage, and excessive carbon source. Dosing and other problems, to achieve the effect of saving pharmaceutical costs and electric energy, solving the problem of poor denitrification stability and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

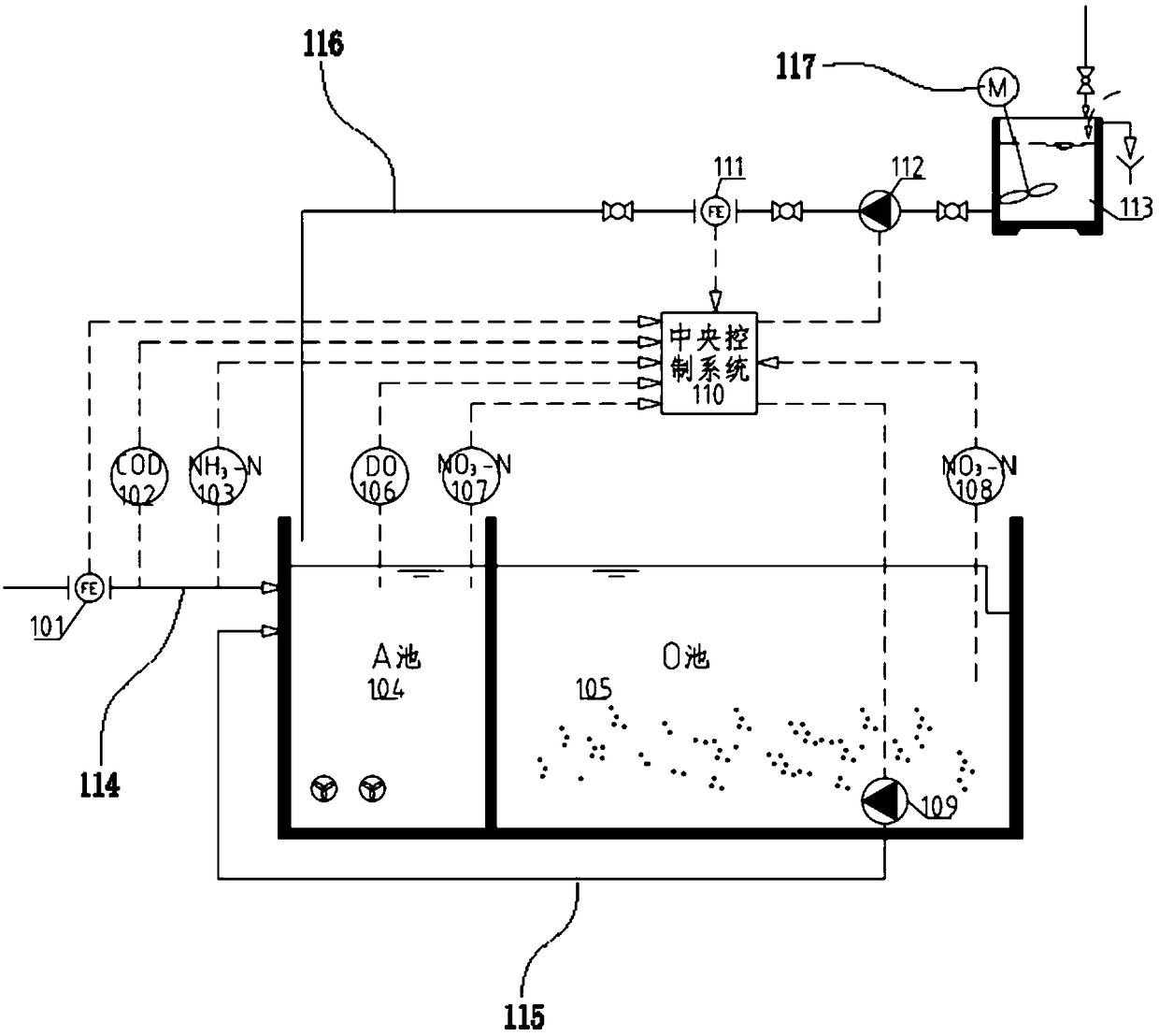

[0019] like figure 1 As shown, a kind of AO process denitrification carbon source dosing optimization control device of the present invention includes A pool 104, O pool 105, first pipeline 114, second pipeline 115, third pipeline 116, agitator 117, water inlet Flow meter 101, influent COD analyzer 102, influent ammonia nitrogen analyzer 103, dissolved oxygen meter 106, first nitrate nitrogen sensor and measuring instrument 107, second nitrate nitrogen sensor and measuring instrument 108, frequency conversion internal reflux pump 109, central Control system 110, carbon source dosing flowmeter 111, variable frequency carbon source dosing pump 112 and carbon source box 113;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com