Nitrile glove production technological waste water treatment technological method

A production process and technology for nitrile gloves, which are applied in the field of treatment of wastewater from the production process of nitrile gloves, can solve problems such as inability to meet environmental protection policy requirements, and achieve the effects of stable treatment effect, reduced equipment investment and operating costs, and low pharmaceutical costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

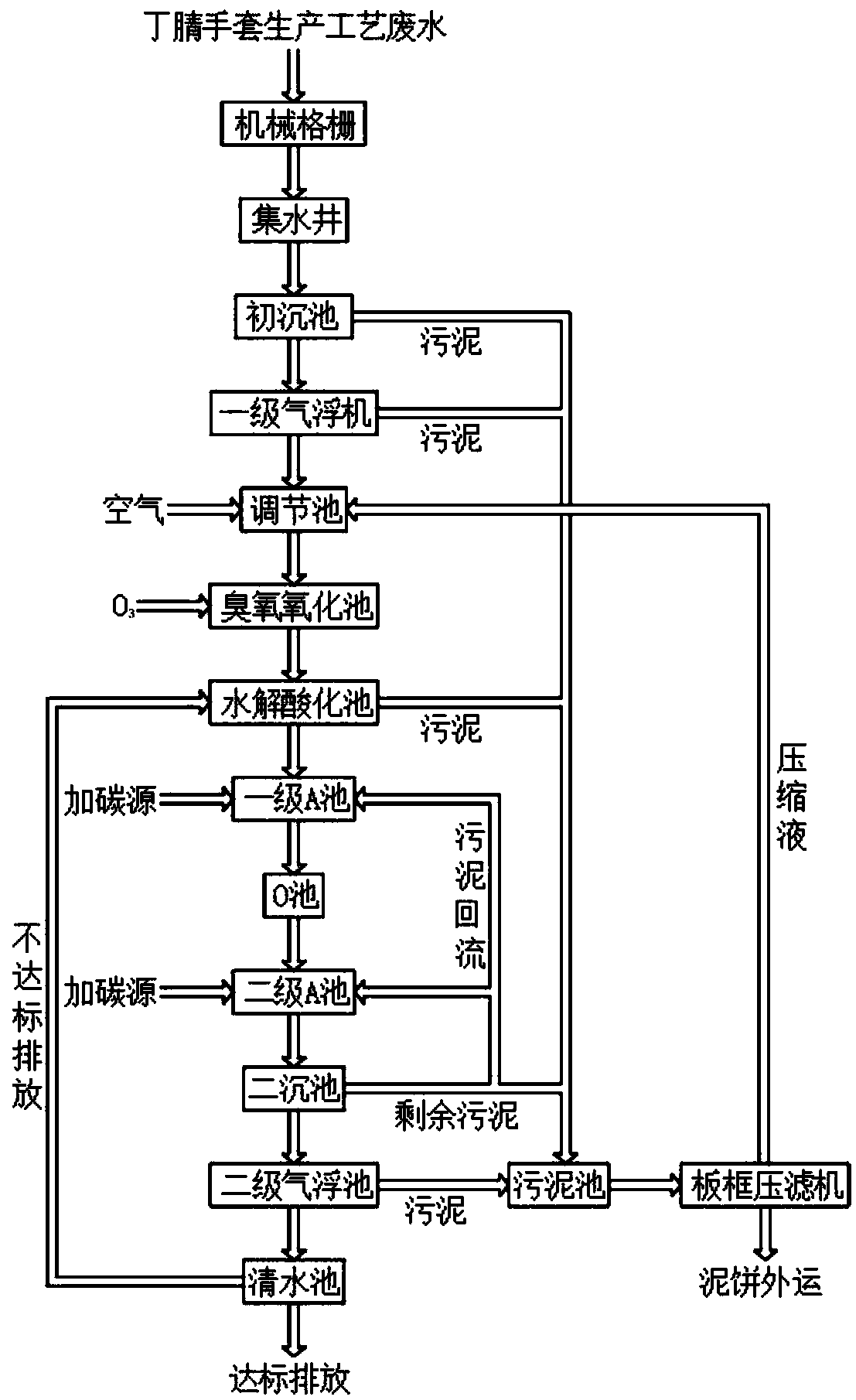

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0036] see figure 1 , an embodiment provided by the present invention:

[0037] The initial water quality of nitrile glove production process wastewater produced by a company in Hebei is 400mg / L COD, 130mg / L BOD5, 300mg / L total nitrogen, 1200 mg / L salt content, 500mg / L SS, and 7-8.5 pH. Adopt the treatment method of a kind of nitrile glove production process waste water of the present invention to process it, design treatment capacity is 4500m3 / d, its main processing step is:

[0038] (1) The waste water passes through the 5mm mechanical grille, then through the water collection well and the primary sedimentation tank, and then is lifted to two 110m3 / h first-stage a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com