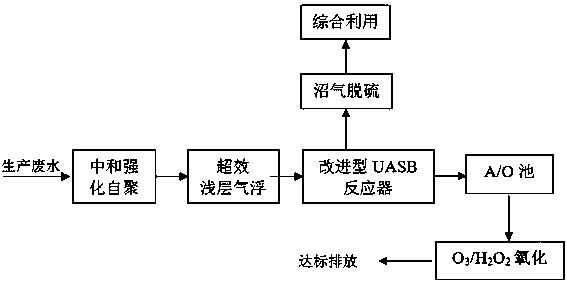

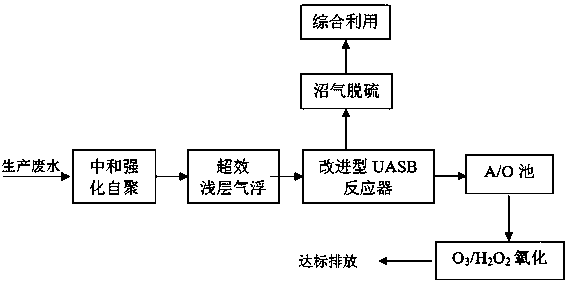

Method for treating production wastewater of methyl methacrylate produced by isobutene oxidation method

A technology for the production of methyl methacrylate and waste water, which is applied in the direction of oxidized water/sewage treatment, water/sewage treatment, natural water treatment, etc., can solve the problems of single raw material, single composition of waste water, short reaction steps, etc., and achieve improved reaction The effect of volume load, saving capital investment and saving drug cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention rather than limit the scope of the present invention, and those skilled in the art can make some non-essential improvements and adjustments based on the content of the above invention.

[0028] The method for treating wastewater produced by methyl methacrylate (MMA) in this embodiment, the steps include:

[0029] (1) Wastewater neutralization and enhanced self-polymerization treatment, the production wastewater in the production workshop is adjusted to pH 10-10.5, and after stirring for 8-16 hours, it is mixed with other wastewater in the factory area (including reactor and pipeline alkali washing wastewater, condensed water, external flushing water, Special equipment circulating water, domestic sewage, etc.) are homogeneously mixed, and the mixed wastewater is adjusted to pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com