Restoration process for polluted soil containing hexavalent chromium

A technology of polluted soil and hexavalent chromium, applied in the field of polluted soil remediation, can solve the problems of long microbial remediation cycle, allergies or skin cancer, and high processing costs, saving cleaning agents and remediation costs, eliminating soil environmental risks, and saving chemicals. The effect of the medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

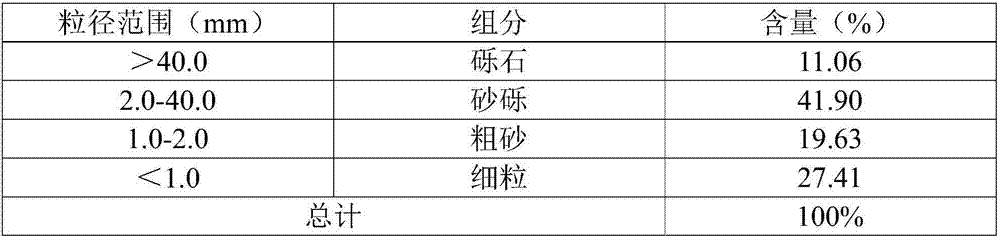

[0028] A sample of soil contaminated by hexavalent chromium was taken at a contaminated site in Gansu. The soil of the site was mainly coarse particles, and the particles were mainly coarse sand, gravel and gravel. The results of soil particle size analysis are shown in Table 1:

[0029] Table 1 Results of soil particle size analysis

[0030]

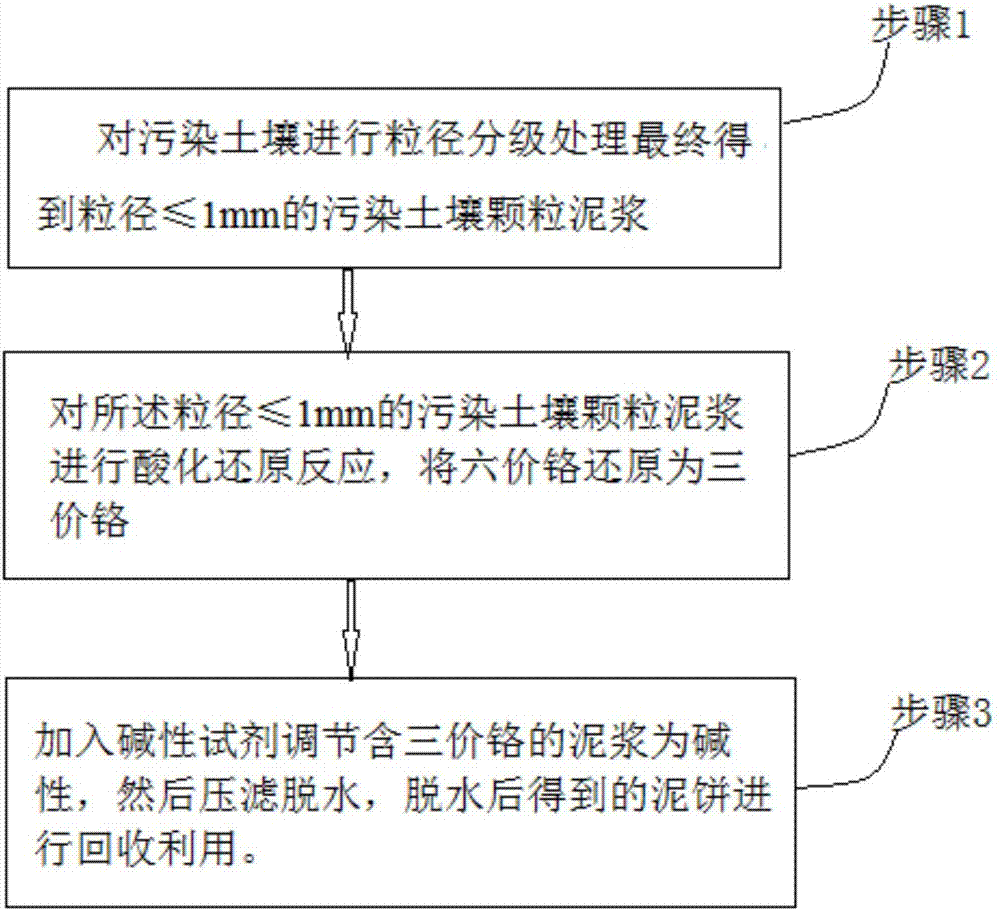

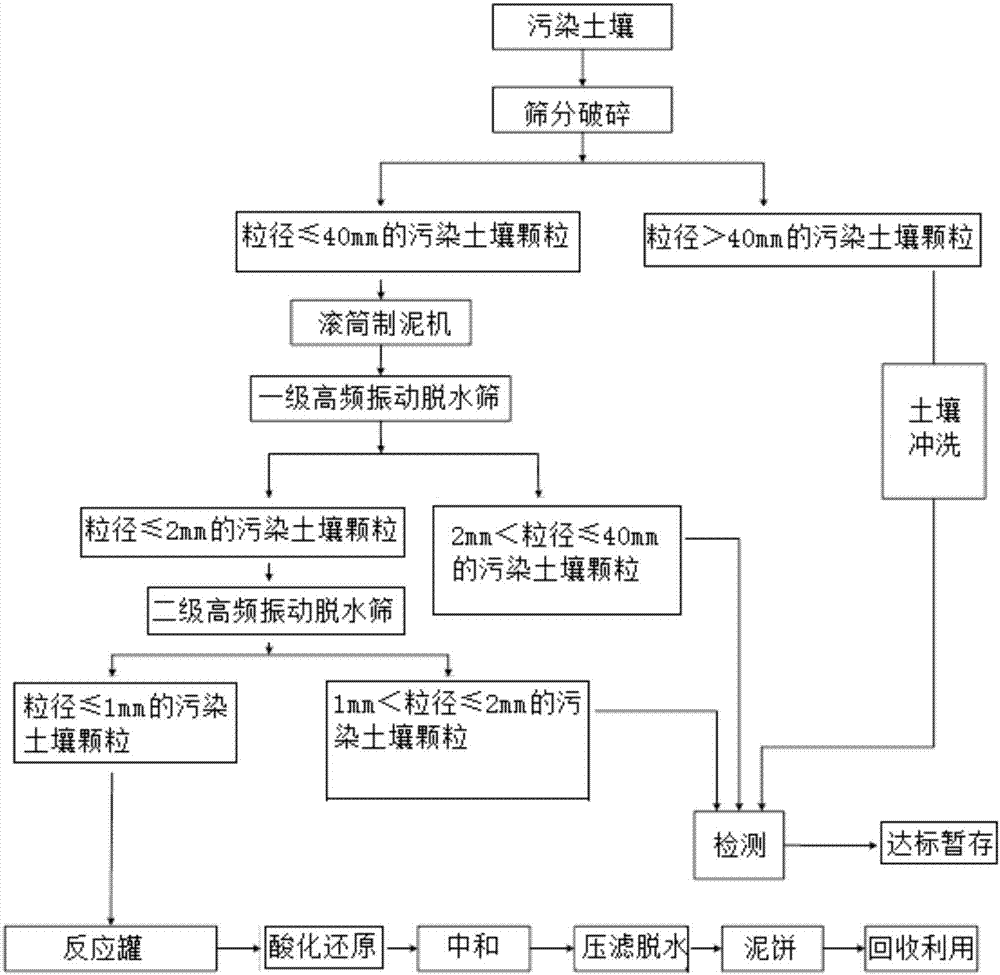

[0031] After testing, the hexavalent chromium in the contaminated soil samples seriously exceeded the standard. Therefore, the following processes were used to repair the contaminated soil, such as figure 1 with figure 2 As shown, they are respectively a schematic flow diagram of the remediation process of contaminated soil containing hexavalent chromium in the present invention and a specific flow chart of the remediation process of contaminated soil containing hexavalent chromium in the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com