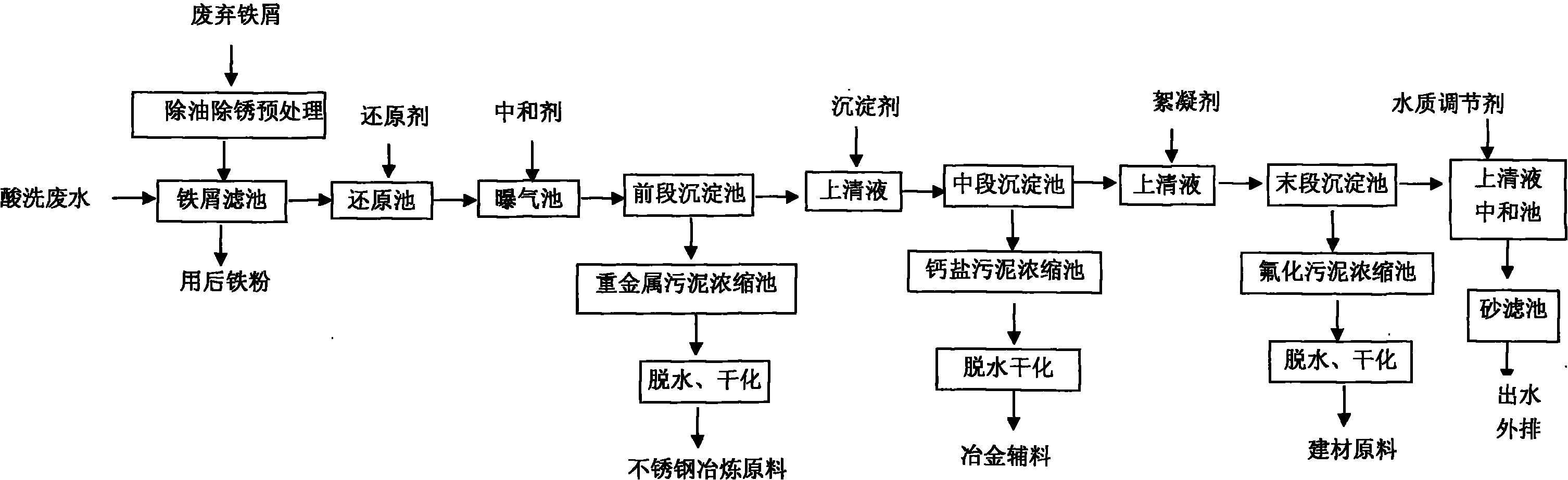

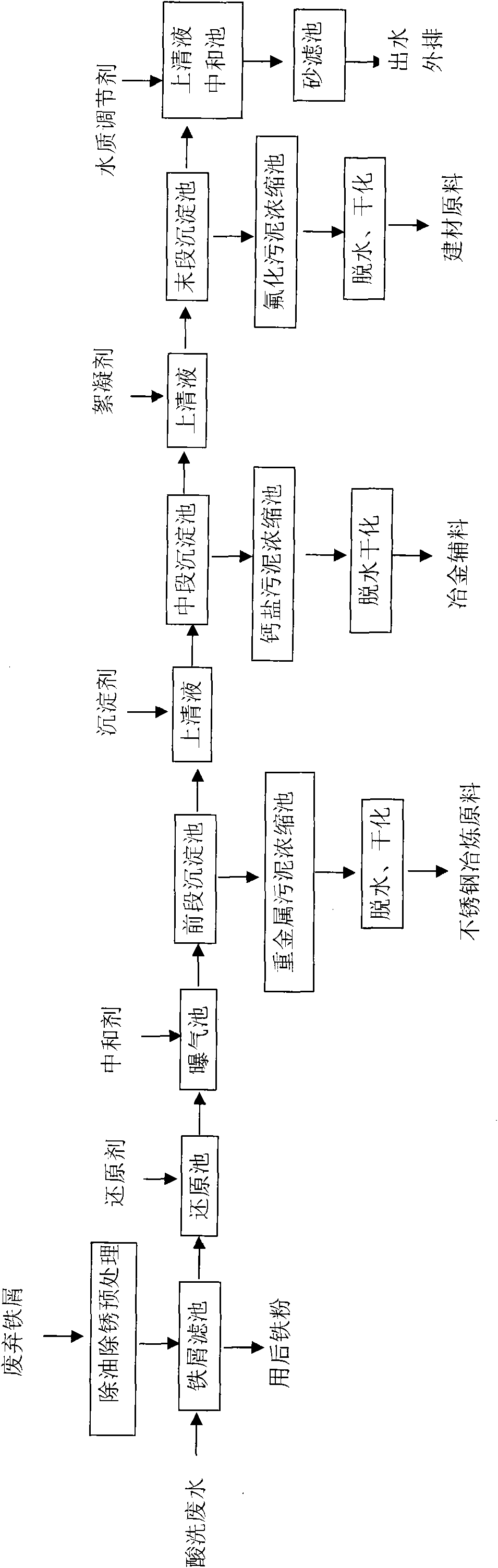

Processing method of stainless steel cold rolling pickling wastewater

A technology for pickling wastewater and its treatment method, which is applied in the fields of metallurgical wastewater treatment, water/sewage treatment, adsorbed water/sewage treatment, etc., and can solve the problems of high cost of chemicals, difficulty in effective utilization of filter residues, secondary pollution of heavy metal concentrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] Shot blasting iron powder from the stainless steel cold rolling process is selected, soaked in 10% NaOH lye for 30 minutes to remove oil, rinsed until the pH value is neutral, soaked in 3% HCl acid solution for 30 minutes to remove rust, and activated Finally, it is mixed with activated carbon particles and porous ceramic fillers in a ratio of 1:0.2:0.3 to form the filter material of the iron filings filter; Upstream filtration method; the iron powder is placed in a stacked shallow pan structure, the shallow pan has 6 layers in total, and the thickness of the filter material at the bottom of the pan is 200mm, and the shallow pan can be dynamically added or removed. will be 0.01m 3 / h of pickling wastewater is introduced into the iron filings filter, and the test aeration head is used for aeration, and the aeration intensity is 10m 3 (air) / m 3 (Wastewater) h, the ratio of iron filings in the filter to the amount of wastewater to be treated is 1:50, the residence time o...

Embodiment 2

[0139] Select the acid-regenerated iron powder from the stainless steel cold rolling process, soak it in 10% NaOH lye for 30 minutes to remove oil, rinse until the pH value is neutral, soak it in 3% HCl acid solution for 30 minutes to remove rust, and activate it Finally, it is mixed with activated carbon particles and porous ceramic filler according to the ratio of 1:0.1:0.5 to form the filter material of the iron filings filter; Upstream filtration method; the iron powder is placed in a layer-by-layer shallow pan structure, the shallow pan has 10 layers in total, and the thickness of the filter material at the bottom of the pan is 10mm, and the shallow pan can be dynamically added or removed. will be 10m 3 The pickling wastewater per hour is introduced into the iron filings filter, and the aeration head is used for aeration in the test. The aeration intensity is 10m3 (air) / m3 (wastewater) h. : 500, the residence time of the wastewater is 30min, and the pH value of the efflu...

Embodiment 3

[0152] Select acid regenerated iron powder and shot blasting iron powder (half each) from the stainless steel cold rolling process, soak in 10% NaOH lye for 30 minutes to degrease, wash until the pH value is neutral, and then use 3% HCl Soak in acid solution for 30 minutes to remove rust, after activation treatment, mix with activated carbon particles and porous ceramic filler according to the ratio of 1:0.1:0.5 to form the filter material of iron filings filter; The pool adopts the dynamic upstream filtration method of water inflow from the bottom and water out from the top; the iron powder is stored in a stacked shallow pan structure, the shallow pan has 12 layers in total, and the thickness of the filter material at the bottom of the pan is 50mm, and the shallow pan can be dynamically added or removed . will be 10m 3 / h of pickling wastewater is introduced into the iron filings filter, and the aeration head is used for test aeration, and the aeration intensity is 5m 3 (ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com