Self-cleaning MBR flat sheet membrane module and cleaning method thereof

A flat membrane, self-cleaning technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as inconvenient cleaning, and achieve the effect of reducing costs and saving pharmaceutical expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

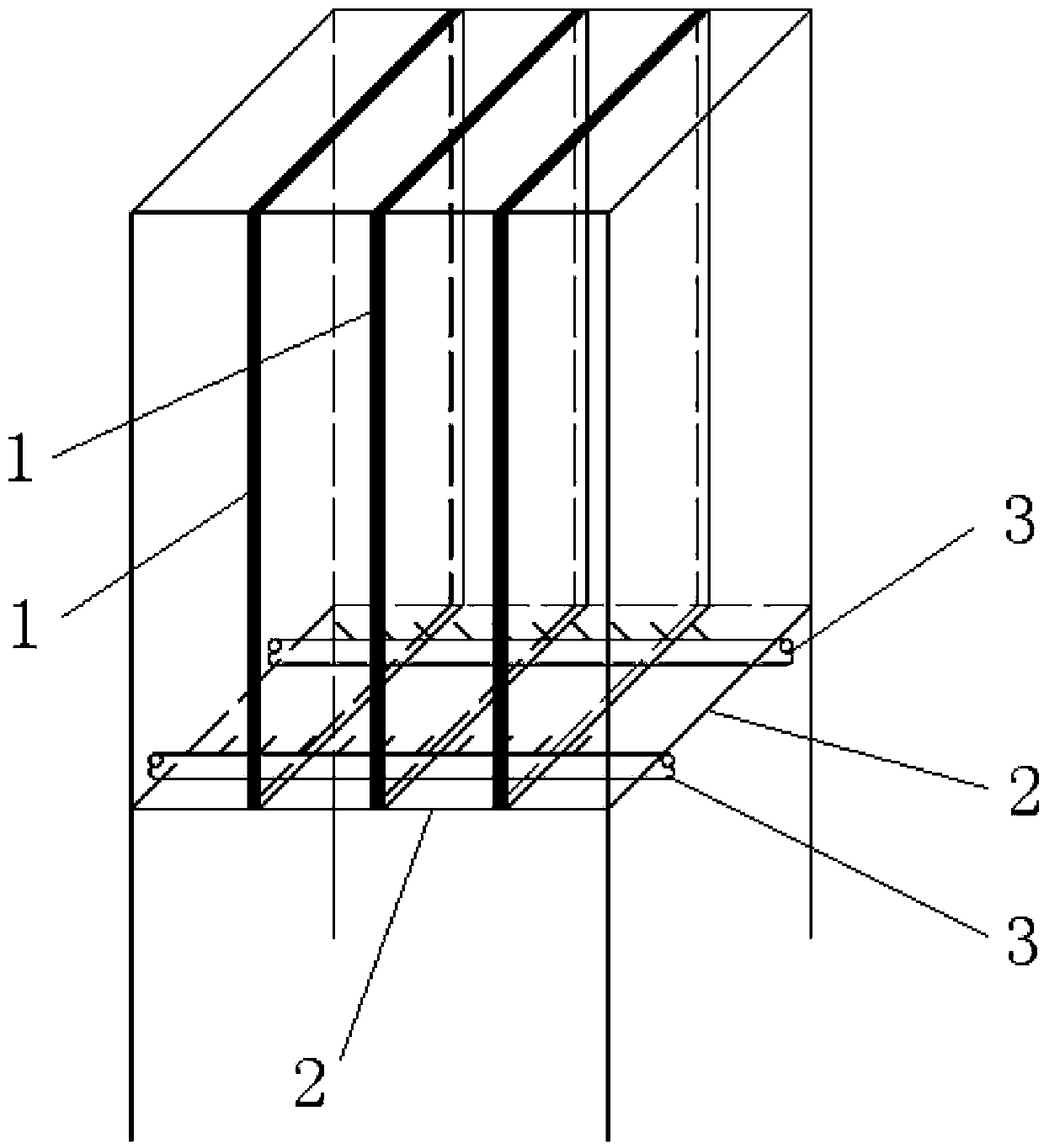

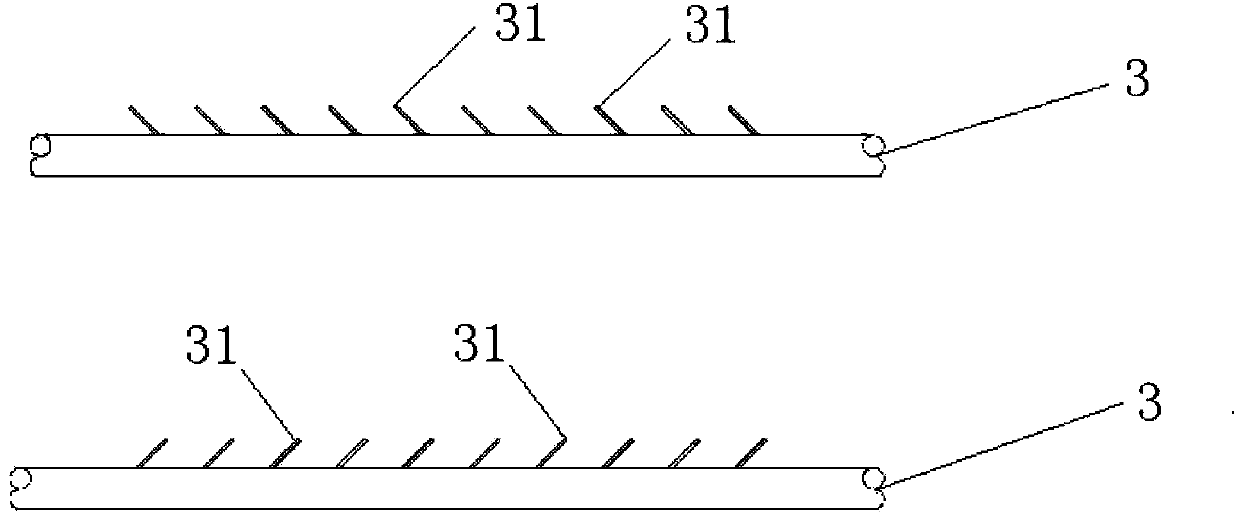

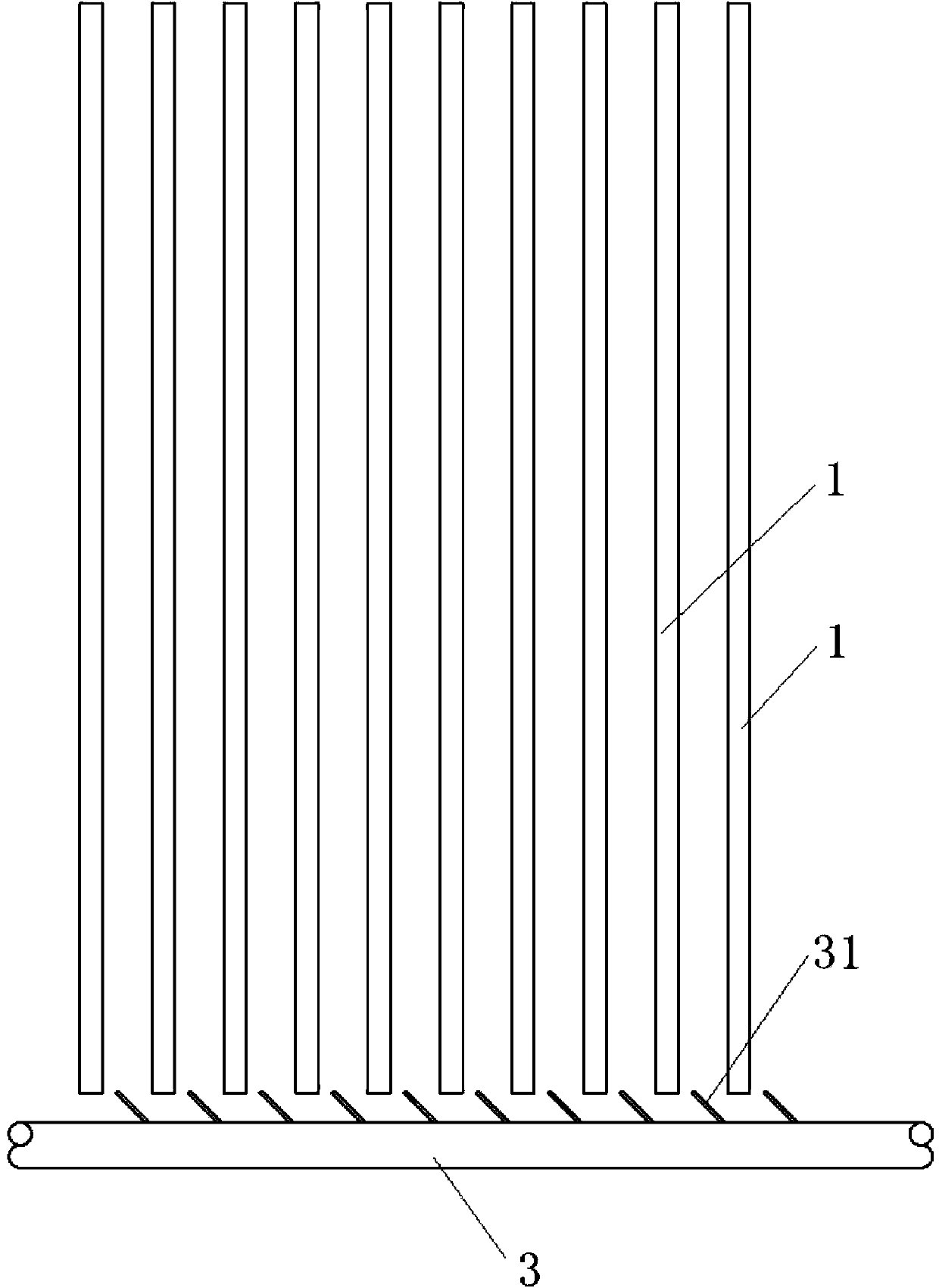

[0030] The self-cleaning MBR flat membrane module of the present invention will be described in detail below with reference to the accompanying drawings. A self-cleaning MBR flat-panel membrane module, comprising a plurality of flat-panel membrane elements 1 stacked at intervals and a frame 2 for fixing the flat-panel membrane elements 1, at least two aeration tubes 3 are arranged on the edge of the flat-panel membrane elements 1 for aeration The tube 3 is provided with a plurality of nozzles 31 for injecting gas towards the flat membrane element 1, such as figure 1 shown.

[0031] Wherein, the spaced stacking arrangement means that there is an interval or gap between two adjacent flat-plate membrane elements 1 . The edge of the flat membrane element 1 is provided with two aeration pipes 3, and the two aeration pipes 3 are arranged on the same side of the flat membrane element 1, such as figure 1 As shown, two aeration pipes 3 are arranged at the lower part of the flat membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com