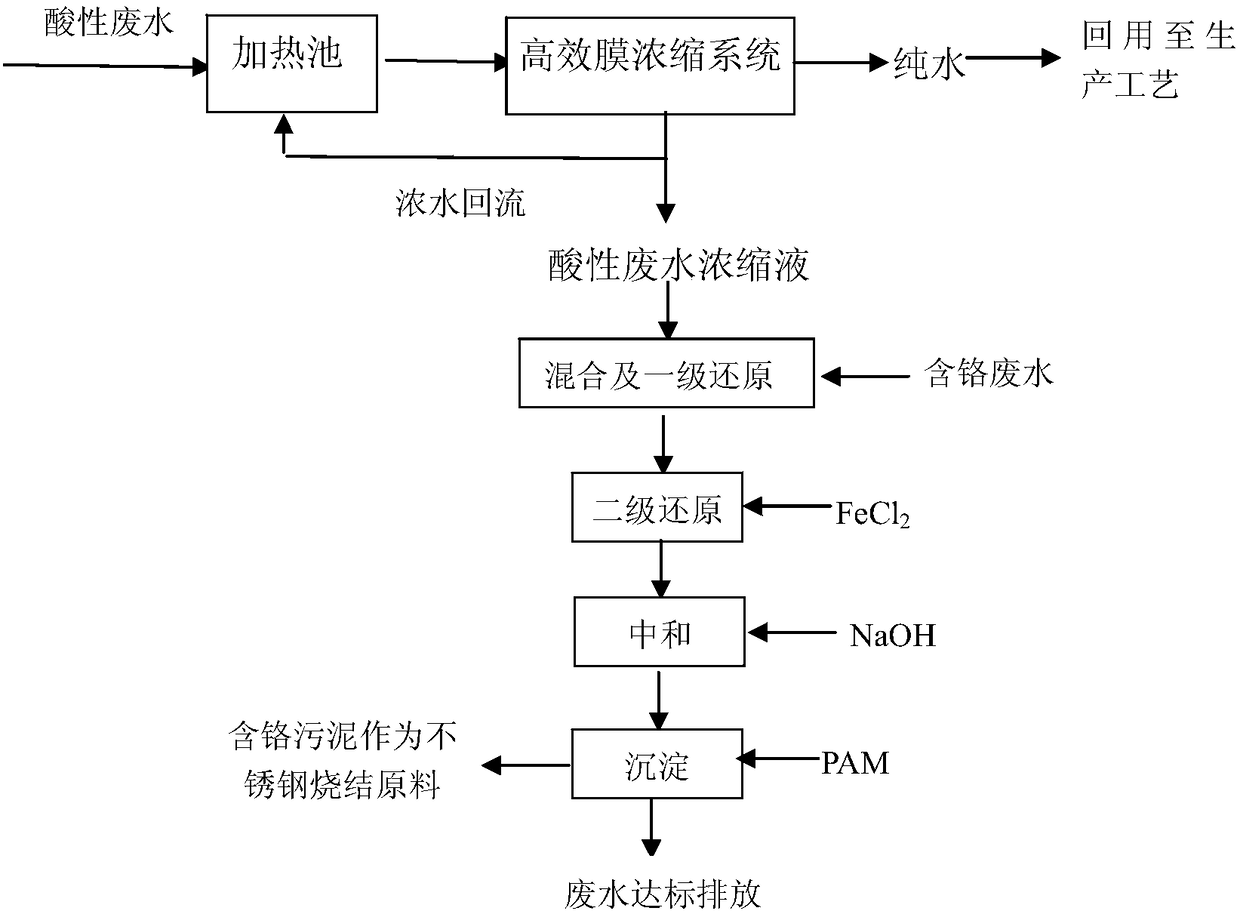

Method for co-treating chromium-containing wastewater and acidic wastewater

A technology of acid wastewater and collaborative treatment, applied in the field of water treatment, can solve the problems of no good outlet for concentrated brine, high cost, high conductivity of wastewater, etc., achieve good social and environmental benefits, save disposal costs, and save operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

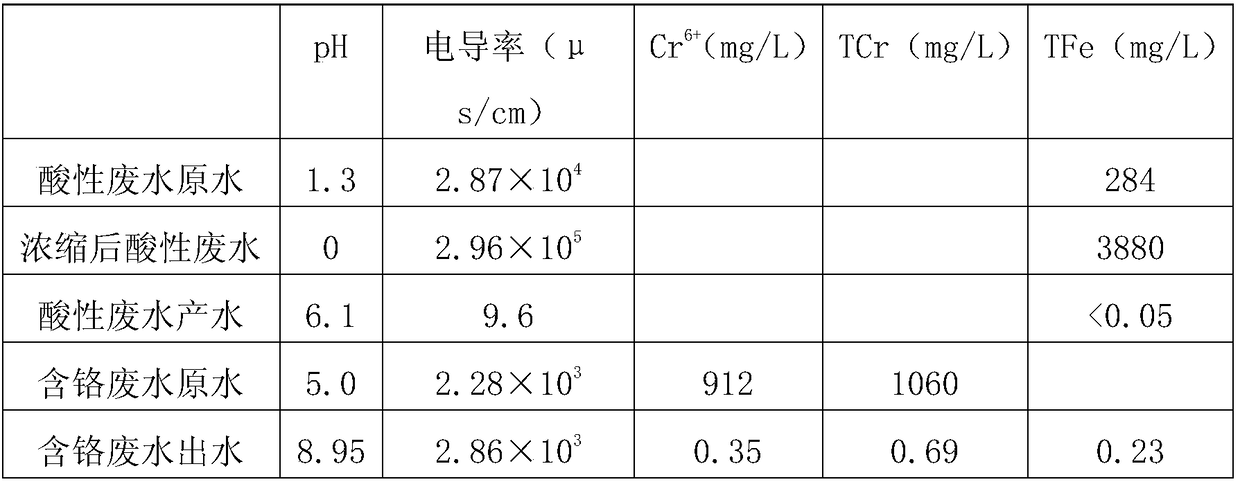

Method used

Image

Examples

Embodiment

[0054] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the invention is not limited to the following examples.

[0055] Cold-rolling pickling wastewater first enters the pretreatment system for filtration to filter out particulate matter above 5-30 μm. The filtration facilities and pipelines used need to be resistant to acid corrosion. Filters with fillers such as quartz sand and anthracite can be used, or inorganic ceramic membrane filtration or sintered organic membrane filtration can be used.

[0056] The backwash water produced by the filter backwash is mixed with dilute alkali wastewater, and the suspended solids in the backwash water are also mixed into the sludge produced by dilute alkali wastewater.

[0057] Firstly, the filtered pickling wastewater is heated at 50-100°C with low-temperature steam on site, enters the water storage tank, and is lif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com