Glass fibre wastewater pretreatment method

A glass fiber and pretreatment technology, applied in water/sewage multi-stage treatment, flotation water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of glass fiber wastewater with large fluctuations in water quality, and achieve savings in chemical costs, The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the content of the patent of the present invention, the technical solutions of the present invention will be further described through specific examples below, but the present invention is not limited to the examples.

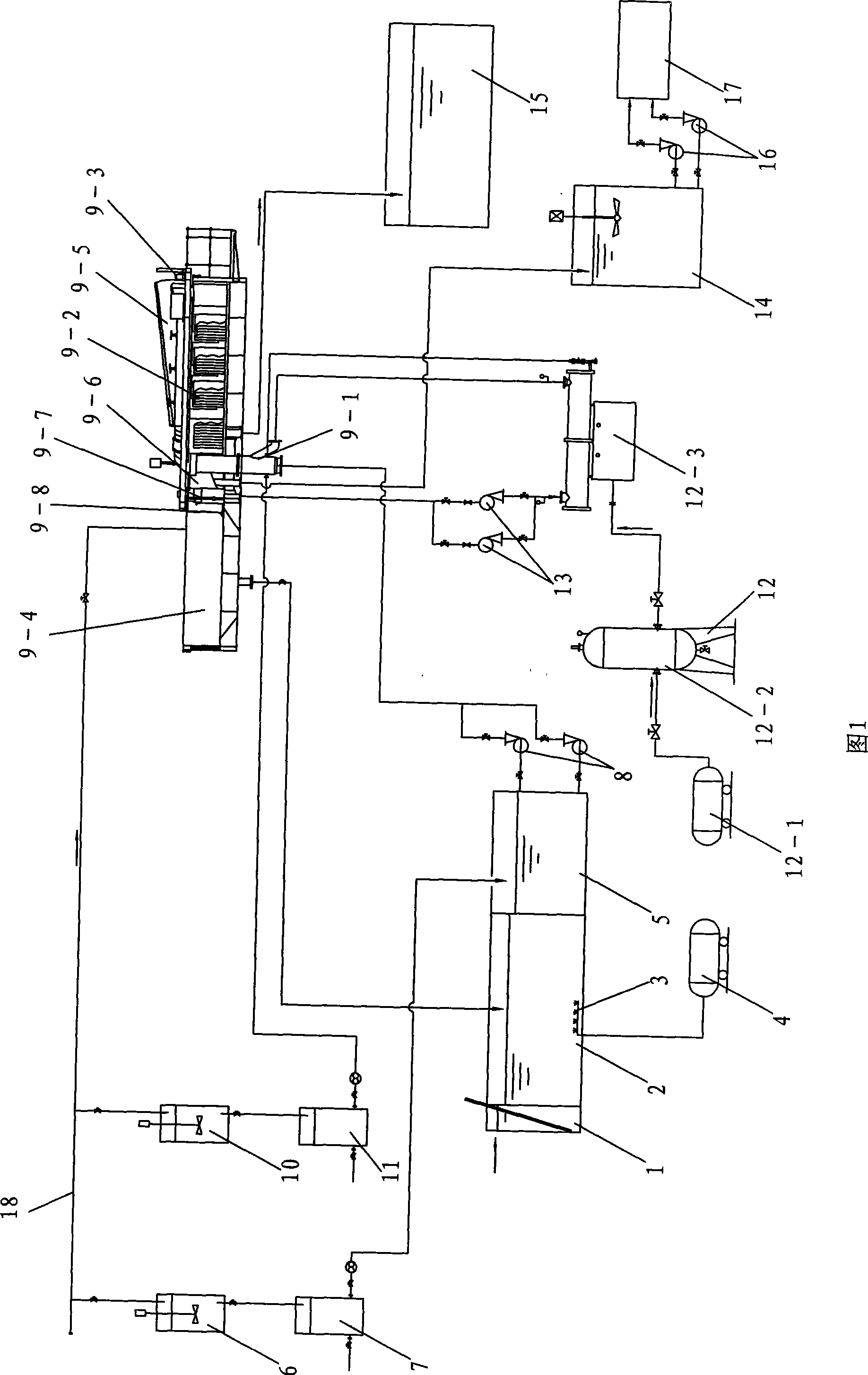

[0017] A. Referring to Fig. 1, the method for pretreatment of glass fiber wastewater in the embodiment of the present invention firstly flows the wastewater from the workshop to the regulating pool 2 through the ditch, and before entering the regulating pool, a mechanical grid 1 is added to intercept the larger impurities and residues in the wastewater, In order to avoid mechanical and equipment failures caused by debris and residues entering the system, the aeration head 3 is installed in the adjustment tank 2, and the blower 4 is used to pre-aerate the wastewater, and at the same time, it has the effect of stirring, mixing and equalizing;

[0018] B. The waste water flows automatically to the coagulation reaction tank 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com