Method for producing impurity-bearing liquid calcium chloride by utilization of converter dedusting wastewater

A converter dedusting wastewater and calcium chloride technology, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problems of long process flow, improve the ecological environment, avoid environmental pollution, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

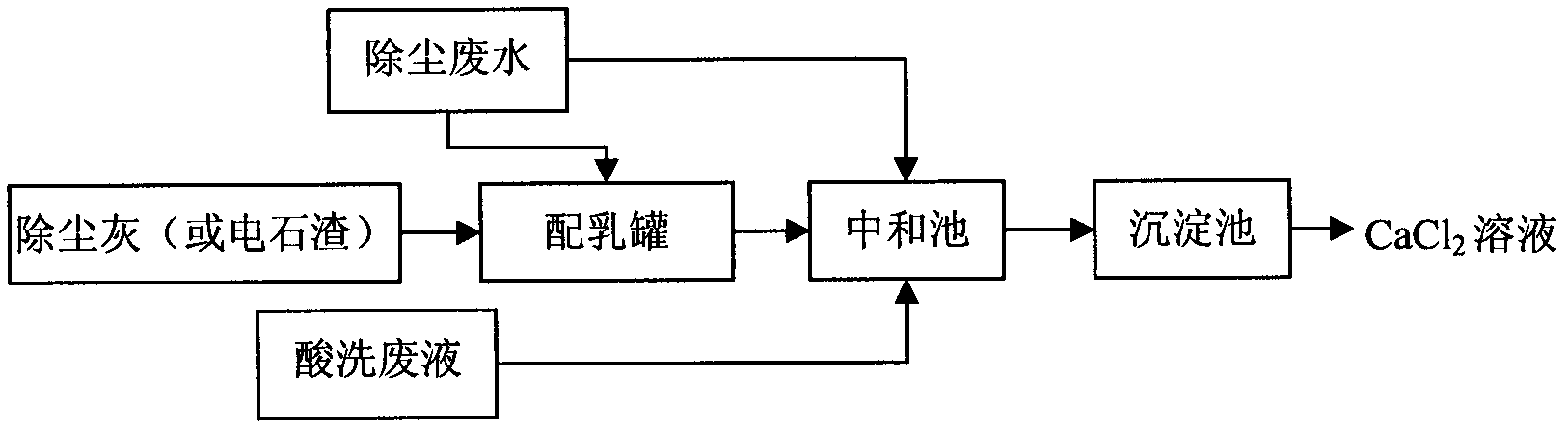

Embodiment 1

[0020] Check that the molar concentration of HCl in the pickling waste liquid is 2.53mol / L, and the mass fraction of CaO in the dust removal dust of the LF furnace is 50.20%; 2 The molar concentration of the wastewater solution is 0.18mol / L. The specific process is as follows: 972.69kg and 10m 3 The cold-rolled acid-containing waste water was added to the milk mixing tank, and after stirring for 1 hour, lime milk was made; then the lime milk and 9.96m 3 The pickling waste liquid is added to the neutralization tank and injected into the 50.04m 3 Converter dedusting wastewater, the neutralized solution flows into the sedimentation tank for static precipitation, and the upper layer is clear as CaCl 2 The impurity-containing liquid calcium chloride solution with a molar concentration of 0.18mol / L.

Embodiment 2

[0022] Check that the molar concentration of HCl in the pickling waste liquid is 2.53mol / L, and the mass fraction of CaO in the carbide slag is 63.00%; determine the required preparation of impurity-containing CaCl 2 The molar concentration of the solution is 0.10mol / L. The specific process is as follows: 417.65kg of calcium carbide dry slag and 5.20m 3 The converter dedusting waste water was added to the milk mixing tank, and after stirring for 1 hour, lime milk was made; then the lime milk and 5.53m 3 The pickling waste liquid is added to the neutralization tank and injected into the 59.27m 3 The converter dedusting wastewater, the neutralized solution flows into the sedimentation tank for static precipitation, and the upper layer is clear as CaCl 2 A liquid calcium chloride solution containing impurities with a molar concentration of 0.10 mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com