Liquid-solid interference fluidized bed separator as well as separating method and application thereof

A technology of sorting machine and fluidized bed, which is applied in the fields of chemical industry and mineral processing. It can solve the problems of uniform and stable density in easily damaged sorting areas, poor control accuracy of bed density, and large fluctuations in average density, so as to maintain fluidization. And sorting performance, improve uniformity and stability, shorten the effect of residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: liquid-solid interference fluidized bed separator

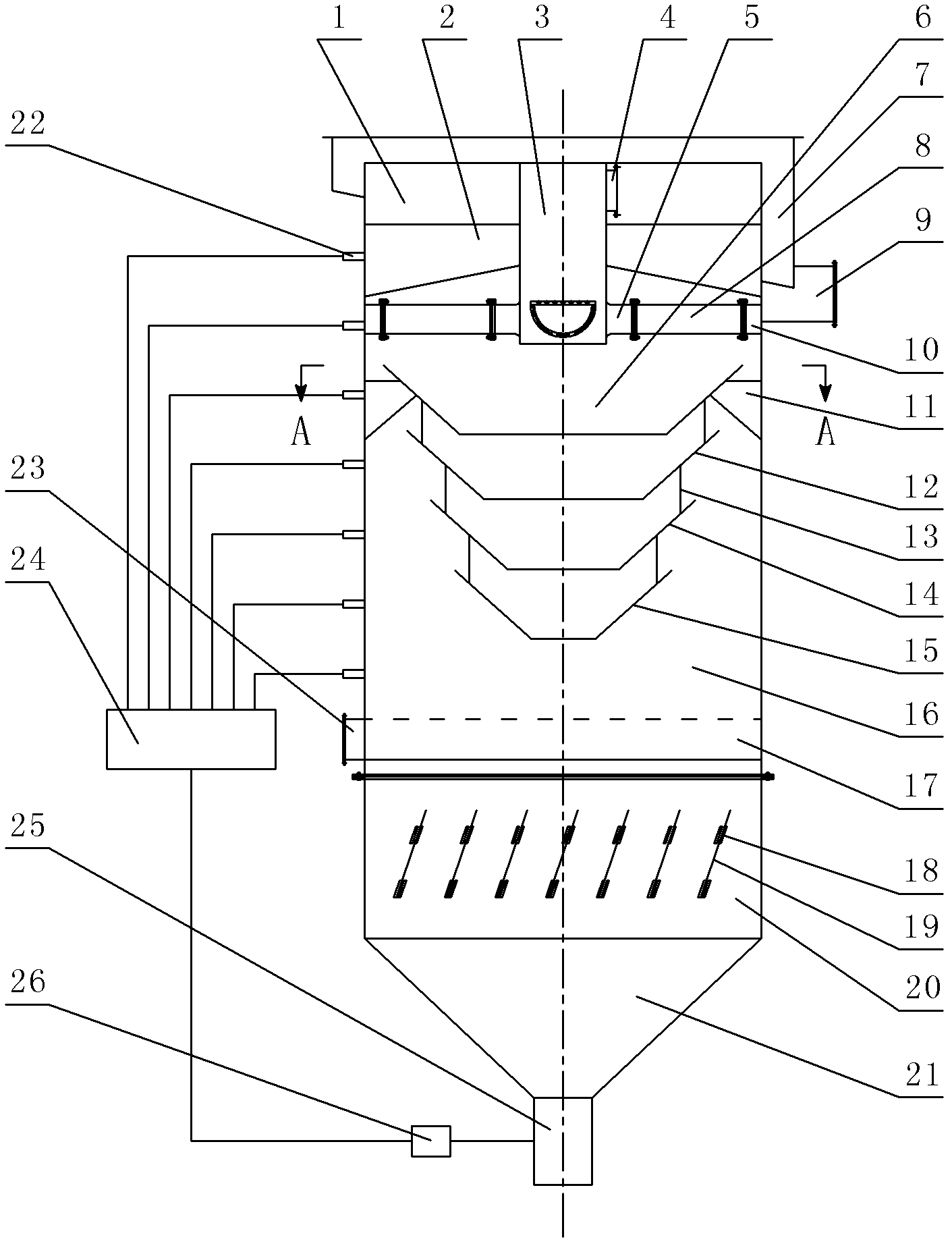

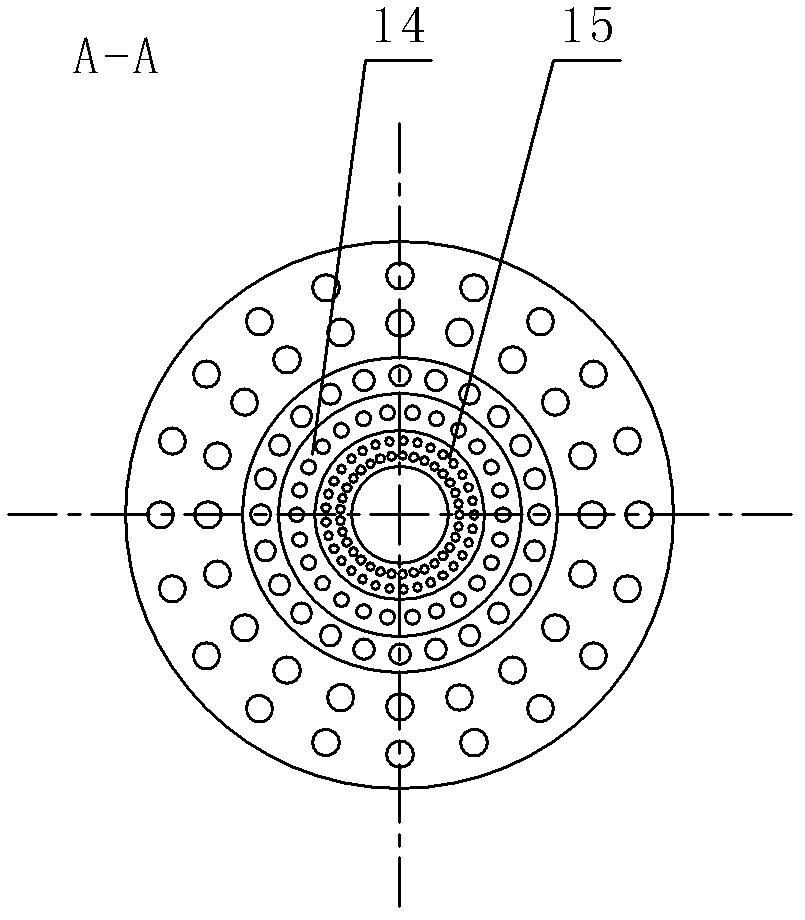

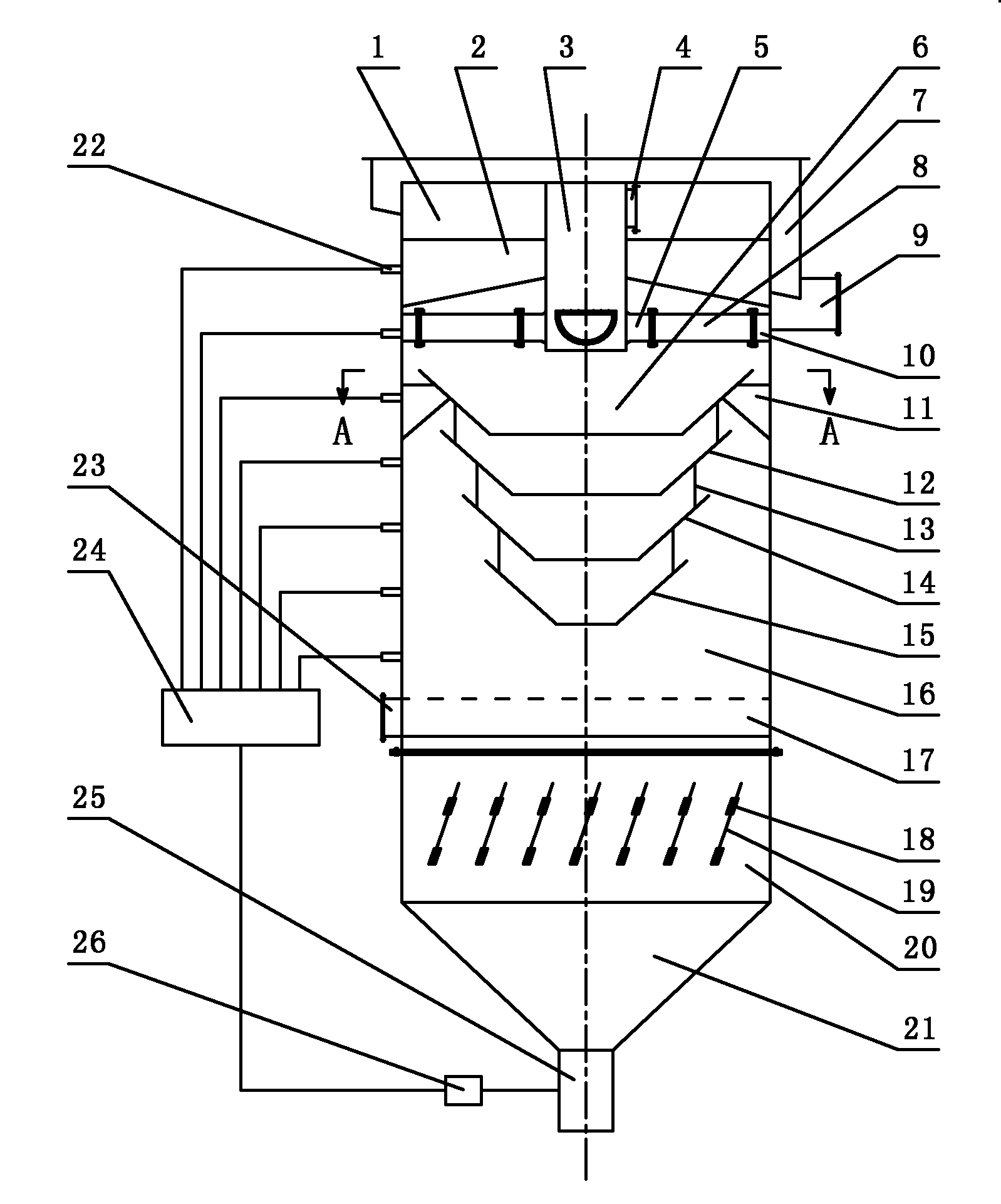

[0035] figure 1 As shown, the liquid-solid interference fluidized bed separator of the present invention mainly includes: a separator housing, a feeding device, a deflector, a fluid distribution device, a floating object collecting device, a sinking object collecting device and a control system.

[0036] The shell of the separator 1 is composed of an upper cylinder 16 , a lower cylinder 20 connected to the upper cylinder 16 and an inverted conical sink 21 arranged at the bottom of the lower cylinder 20 .

[0037] The feeding device is located inside the sorting machine housing 1 and is arranged on the upper part of the upper cylinder 16, wherein the upper center of the upper cylinder 16 is provided with a vertical feed pipe 3, and the vertical feed pipe 3 passes through the support 2 and the upper cylinder. The inner walls of 16 are connected, and the bottom of the vertical feed pipe 3 is evenly arran...

Embodiment 2

[0043] Embodiment 2: the separation method of liquid-solid interference fluidized bed separator

[0044] The liquid-solid interference fluidized bed separator sorting method of the present invention is as follows:

[0045] First, the water flow is fed into the fluid distributor 17 by the water supply port 23 to form a uniform upward flow; the material is sent into the vertical feed pipe 3 through the feed port 4, and after being shunted by the overflow pipe 8, in the upper cylinder 16 A uniform and stable overflow is formed on the cross-section, and the overflow passes downward through the deflector 6 for secondary uniform distribution and step size classification; particles with a sliding velocity equal to the water flow velocity are suspended in the bed to form a uniform and stable density Particles whose slip velocity is smaller than the water flow velocity move upwards, enter the float collection tank 7, and are discharged through the float discharge port 9; particles wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com