Horizontal integrated three phase inner circulation fluidized reactor and its biological reaction process

A technology of three-phase internal circulation and biological reaction, which is applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. Problems such as high equipment manufacturing and installation costs, engineering application limitations, etc., achieve good organic degradation effects, low power consumption, and good biodegradation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiment of the present invention is:

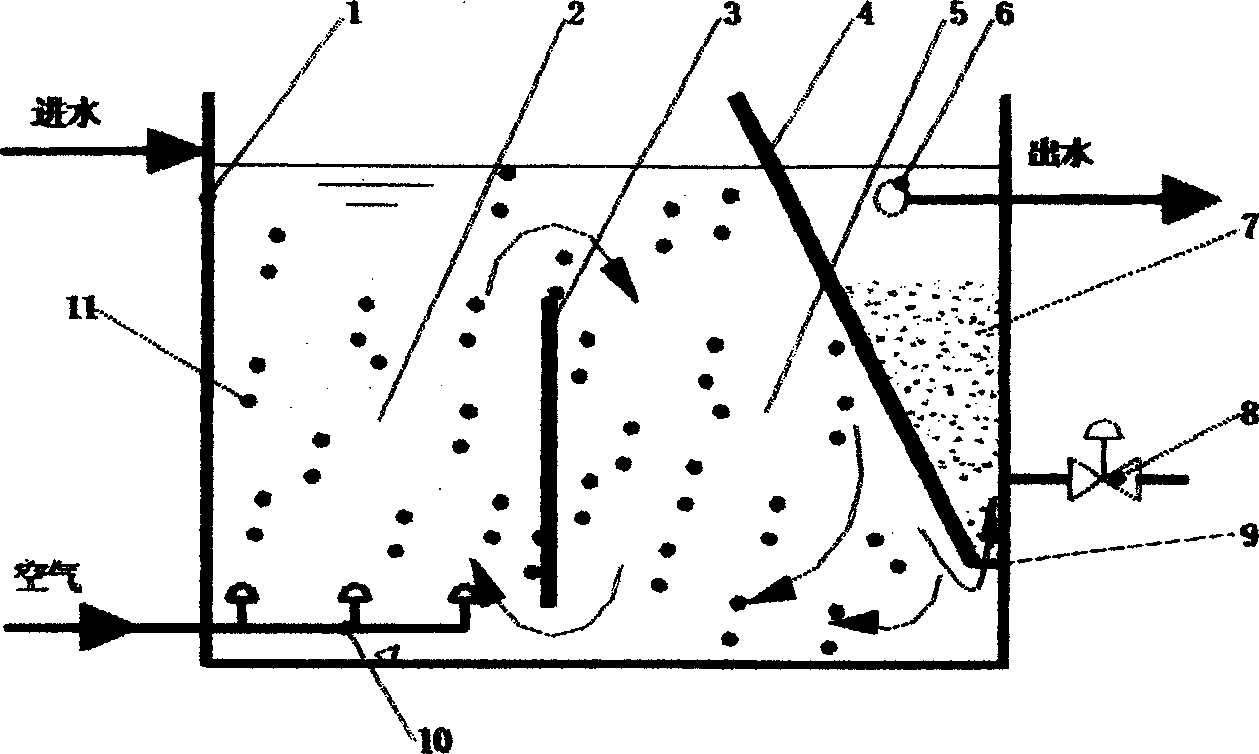

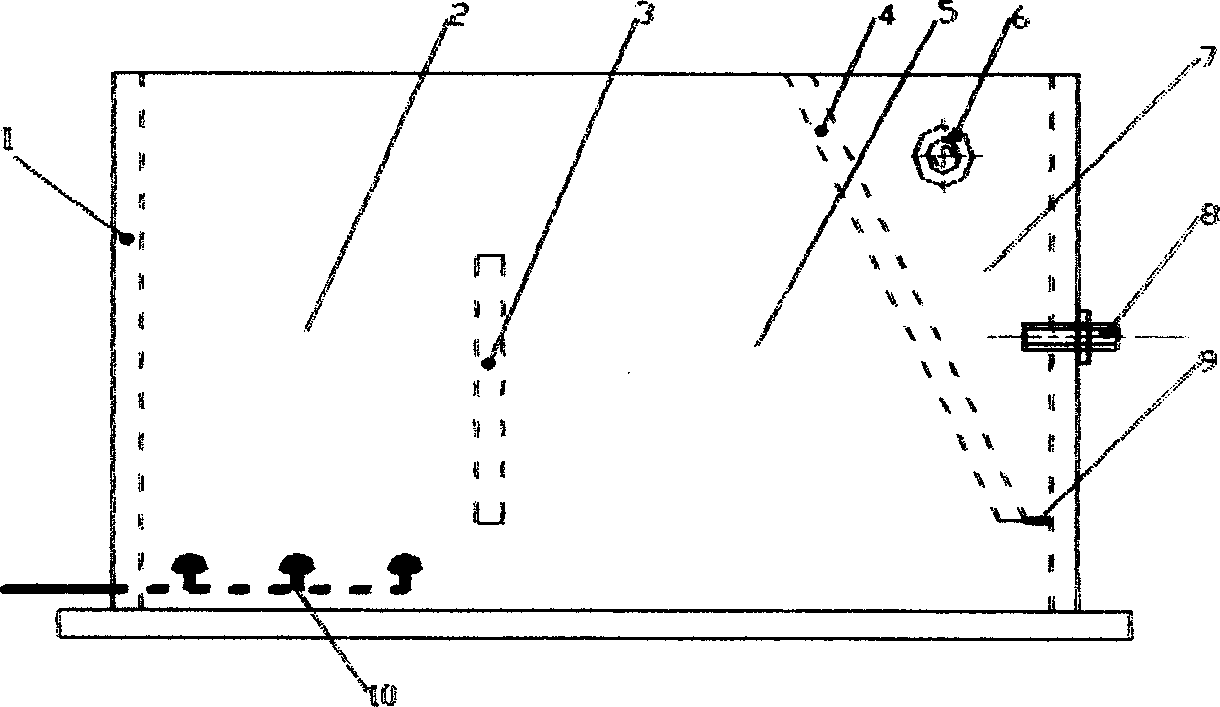

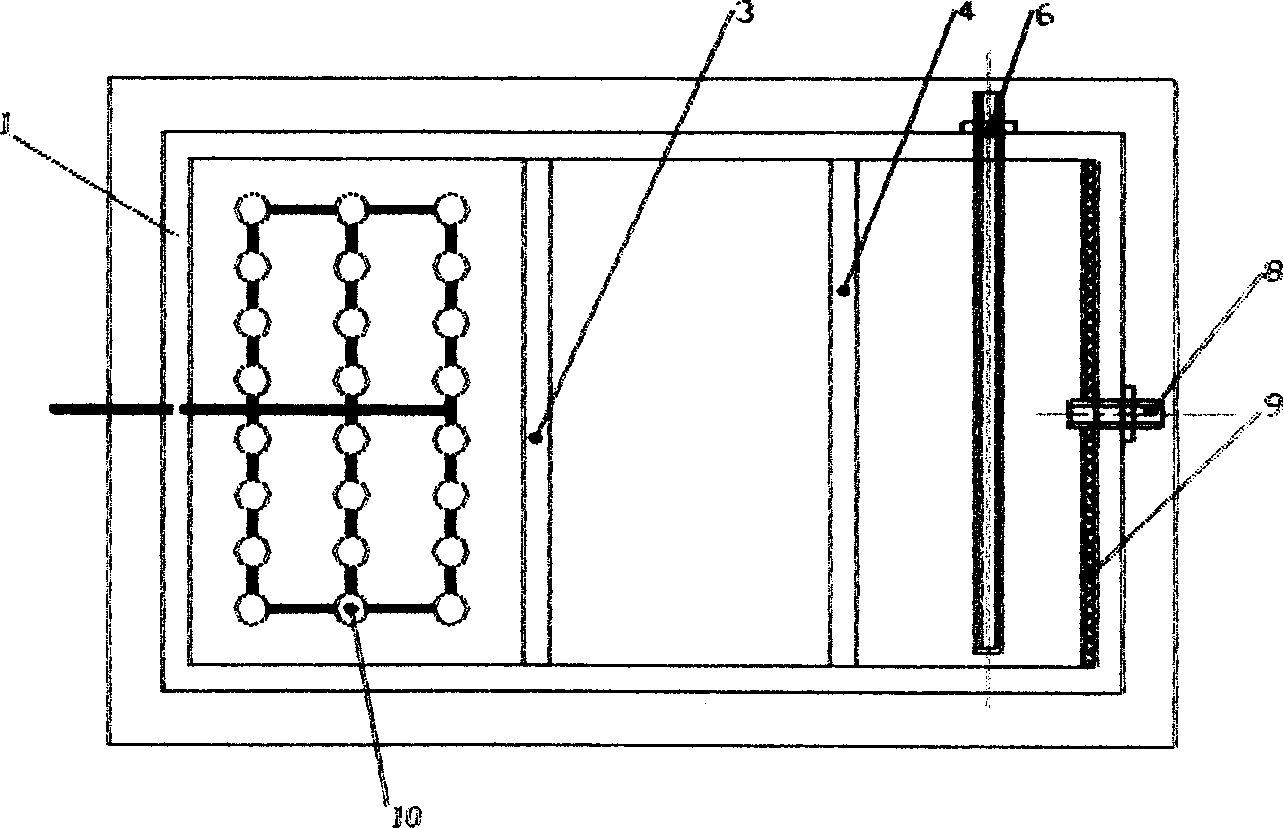

[0027] The reactor is an integrated rectangular horizontal structure. In the reactor box 1, the interior of the reactor box 1 is divided into three areas by the deflector 3 and the settling sloping plate 4, namely the upflow area 2 , the downflow zone 5 and the mud-water separation zone 7, the left and right ends of the deflector 3 are fixed on both sides in the box 1 of the reactor, and the upper and lower ends are respectively separated from the top and bottom of the box 1 of the reactor. distance, the left side of the deflector 3 is the upflow zone 2, and the right side is the downflow zone 5; the sedimentation swash plate 4 is located on one side in the box 1 of the reactor, and its upper part is located on the top of the box 1 of the reactor There is a filter screen 9 at the edge and the lower part, and the other side of the filter screen 9 is connected with the tank 1 of the reactor, and the right side of the sedimenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com