Embedded type cylindrical blast cap with throttling block

An embedded, columnar technology, applied in the direction of chemical/physical processes, chemical instruments and methods, etc., can solve the problems of non-uniform fluidization of bed material, influence of boiler stable operation, inconsistent resistance of wind cap, etc., and achieve simple structure and fixed Simple, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

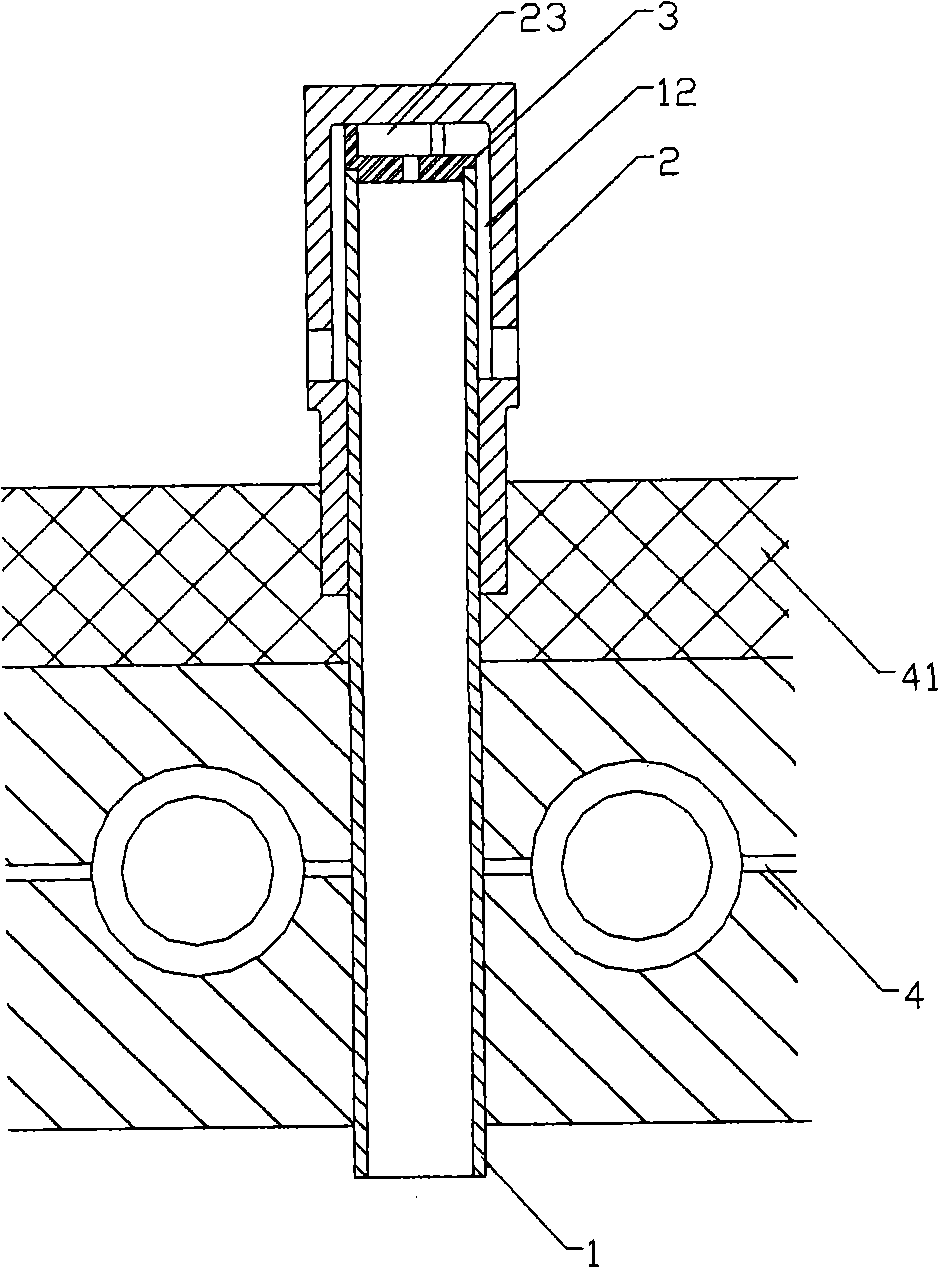

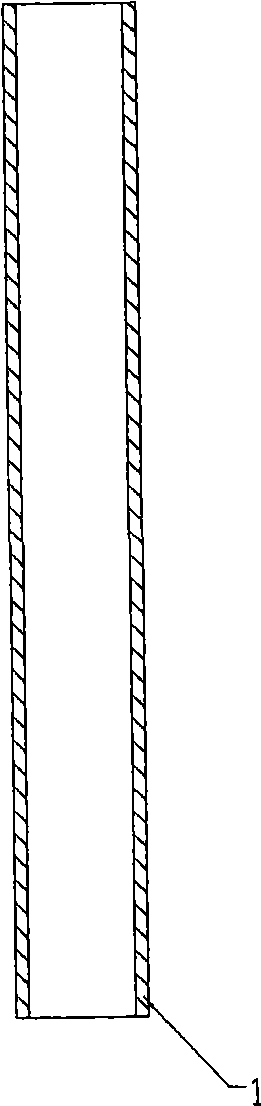

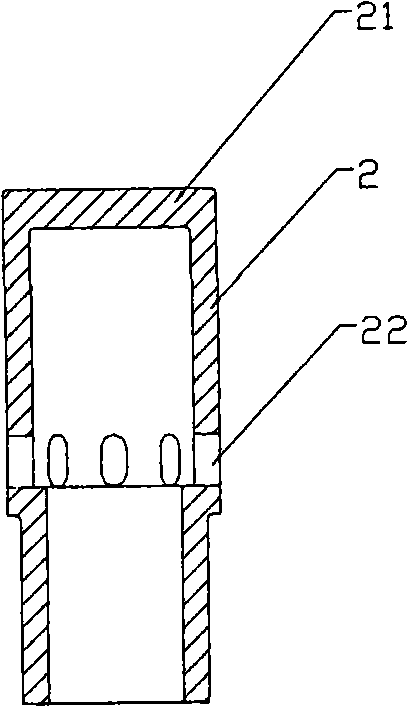

[0048] refer to figure 1 , 2 , 3, 4 and 5, the present invention provides a built-in cylindrical hood with throttle block, which is composed of an embedded tube 1, an outer sleeve 2 and a throttle block 3. The embedded pipe 1 is a straight pipe section with uniform inner diameter, uniform wall thickness, and openings at both ends. The lower end of the outer casing 2 is open. The side wall of the outer casing 2 is provided with a through hole 22. The throttle block 3 is an upper part with three positioning protrusions 31 a circular plate; the throttling block 3 is fully welded to the upper opening of the inner tube 1, and the outer tube 2 is buckled coaxially outside the inner tube 1, and a circular seam 12 is defined between the two; the top surface of the outer tube 21 The inner wall is in close contact with the positioning protrusion 31 on the throttle block 3, so that a baffle area 23 communicating with the annular seam 12 is formed between the outer sleeve top plate 21 an...

Embodiment 2

[0052] refer to Figure 6 , 7 , 8, 9 and 10, the present invention provides a built-in cylindrical hood with throttle block, which is composed of an embedded tube 1, an outer sleeve 2 and a throttle block 3. The inline pipe 1 is a straight pipe section with uniform inner diameter, uniform wall thickness, and openings at both ends. The lower end of the outer casing 2 is open. A circular plate with a protrusion 31; the throttling block 3 is fully welded to the opening of the upper end of the inner tube 1, and the outer tube 2 is buckled coaxially outside the inner tube 1, and a circular seam 12 is defined between the two; the top surface of the outer tube The inner wall of 21 is in close contact with the positioning protrusion 31 on the throttling block 3, so that a baffle area 23 communicating with the annular seam 12 is formed between the outer casing top plate 21 and the throttling block 3; Four throttle holes 32 are processed to make the baffle area 23 communicate with the...

Embodiment 3

[0054] refer to Figure 11 , 12 , 13, 14 and 15, the present invention provides a built-in cylindrical hood with throttle block, which is composed of an embedded tube 1, an outer sleeve 2 and a throttle block 3. The inline pipe 1 is a straight pipe section with uniform inner diameter and openings at both ends. The outer wall is provided with an annular support protrusion 13. The lower end of the outer casing 2 is open. The side wall of the outer casing 2 is provided with a through hole 22. The throttling block 3 is the center. Finishing a circular plate with a throttle hole 32; the throttle block 3 is fully welded to the upper opening of the inner tube 1, the outer tube 2 is buckled coaxially outside the inner tube 1, and a circular seam is defined between the two 12. The bottom end of the outer casing 2 is spot-welded with the support protrusion 13 on the outer wall of the embedded pipe 1. The position of the support protrusion 13 can form a baffle connected with the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com