A high-resolution wide-range micro-mechanical potentiometer lead-out structure and method

A high-resolution, lead-out structure technology, applied in the field of potentiometers, can solve problems such as adjustment accuracy depends on adjustment accuracy, difficult to adjust resistance adjustment accuracy with large resistance range and high resistance, achieve high resistance control accuracy, similar volume, and avoid the effect of manipulator adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

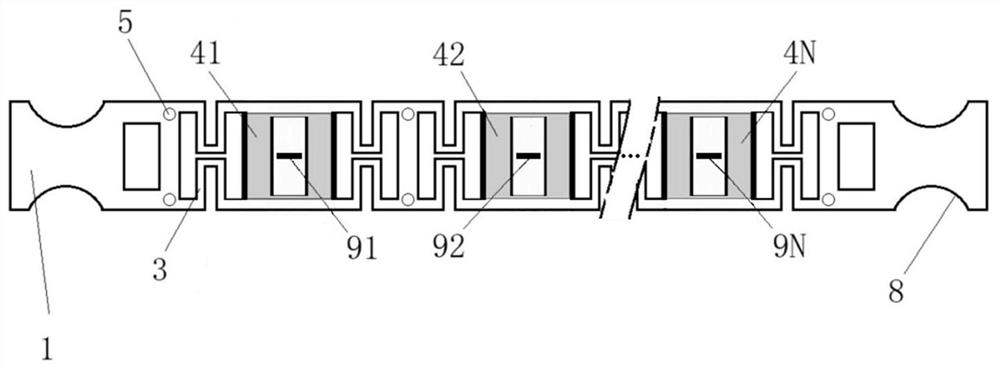

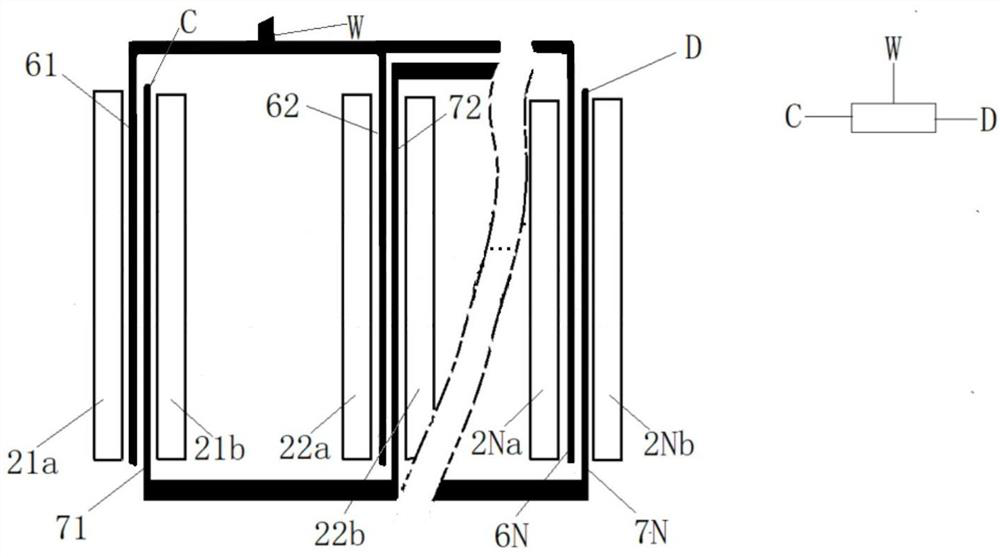

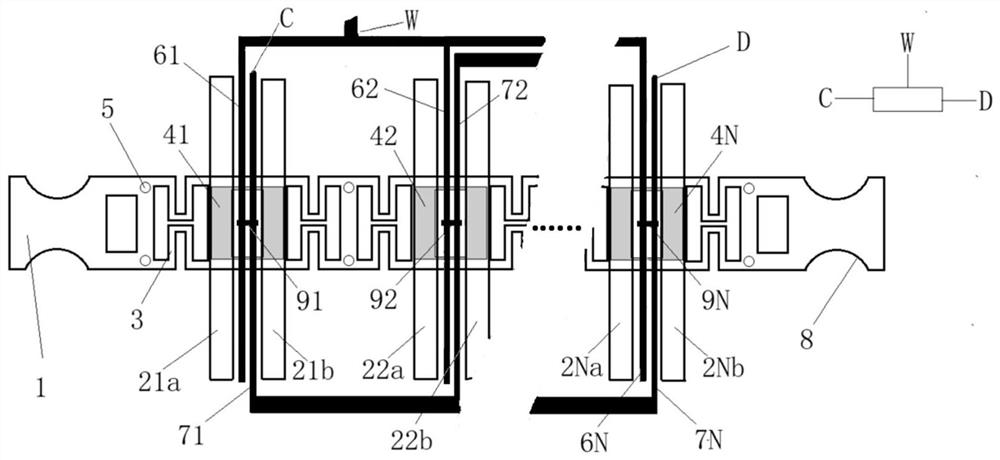

[0022] The invention is a lead-out structure of a micro-mechanical potentiometer with high resolution and wide range. The structure consists of a strip micro-slide 1; control electrodes 21a, 21b, 22a, 22b...2Na, 2Nb of the electrostatic actuator; spring structure 3; induction electrodes 41, 42, 43...4N of the electrostatic actuator; height control Bump 5; metal strips 61, 62, 63...6N; resistance strips 71, 72, 73...7N; positioning groove 8 for linear actuator; contact contacts 91, 92, 93...9N.

[0023] The middle part on the strip-shaped micro-sliding board (1) is composed of N contact units through the transition of the height control unit and the spring structure (3), which are sequentially connected in series and repeated; Electrodes (4) and contact contacts (9); the height control bumps (5) are evenly distributed on the upper and lower ends of the back of the height control unit, and protrude to a certain height from the back of the elongated micro-slide (1);

[0024] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com