Embedded type cylindrical blast cap with throttling block

A built-in, cylindrical technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of uneven fluidization of bed materials, influence of boiler stable operation, deviation of air distribution plate resistance, etc., and achieve simple structure , Easy to fix, large resistance range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

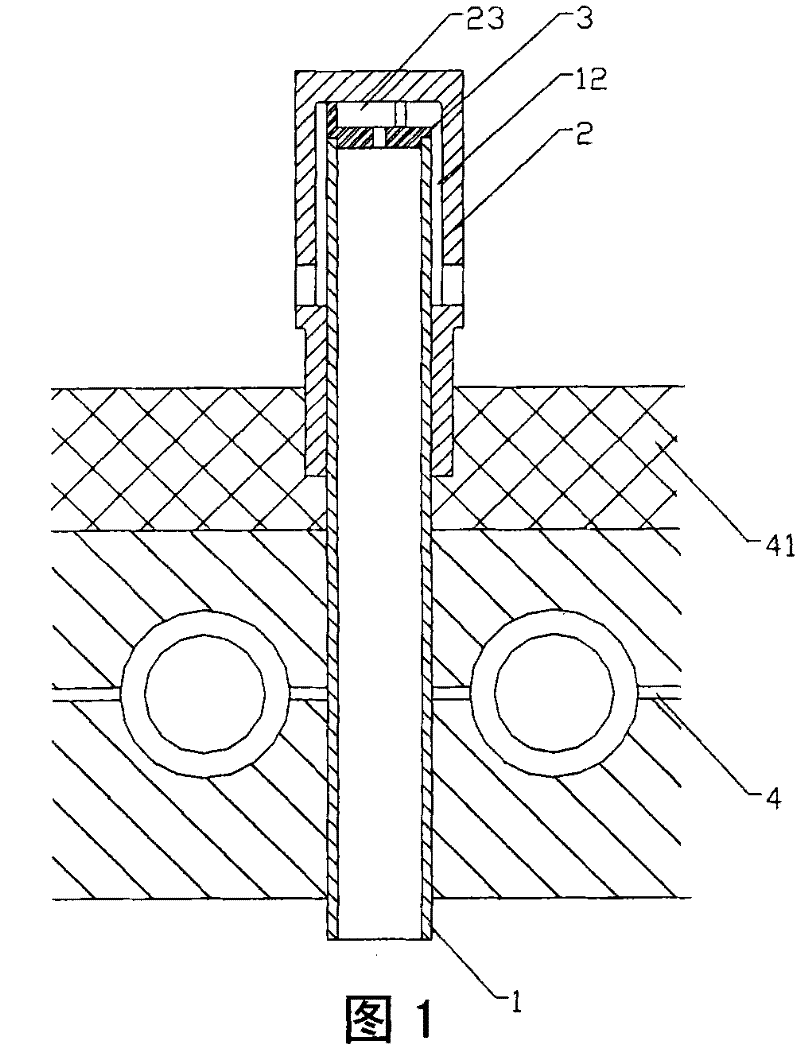

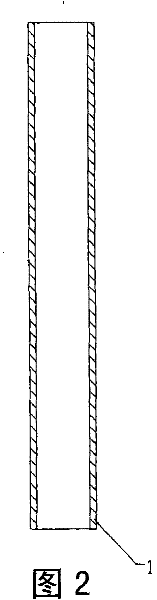

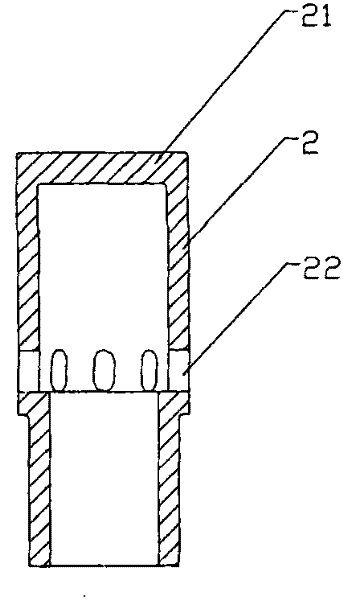

[0048] refer to figure 1 , 2 , 3, 4 and 5, the present invention provides a built-in cylindrical hood with throttle block, which is composed of an embedded tube 1, an outer sleeve 2 and a throttle block 3. The embedded pipe 1 is a straight pipe section with uniform inner diameter, uniform wall thickness, and openings at both ends. The lower end of the outer casing 2 is open. The side wall of the outer casing 2 is provided with a through hole 22. The throttle block 3 is an upper part with three positioning protrusions 31 a circular plate; the throttling block 3 is fully welded to the upper opening of the inner tube 1, and the outer tube 2 is buckled coaxially outside the inner tube 1, and a circular seam 12 is defined between the two; the top surface of the outer tube 21 The inner wall is in close contact with the positioning protrusion 31 on the throttle block 3, so that a baffle area 23 communicating with the annular seam 12 is formed between the outer sleeve top plate 21 an...

Embodiment 2

[0052] refer to Figure 6 , 7 , 8, 9 and 10, the present invention provides a built-in cylindrical hood with throttle block, which is composed of an embedded tube 1, an outer sleeve 2 and a throttle block 3. The inline pipe 1 is a straight pipe section with uniform inner diameter, uniform wall thickness, and openings at both ends. The lower end of the outer casing 2 is open. A circular plate with a protrusion 31; the throttling block 3 is fully welded to the opening of the upper end of the inner tube 1, and the outer tube 2 is buckled coaxially outside the inner tube 1, and a circular seam 12 is defined between the two; the top surface of the outer tube The inner wall of 21 is in close contact with the positioning protrusion 31 on the throttling block 3, so that a baffle area 23 communicating with the annular seam 12 is formed between the outer casing top plate 21 and the throttling block 3; Four throttle holes 32 are processed to make the baffle area 23 communicate with the...

Embodiment 3

[0054] refer to Figure 11 , 12 , 13, 14 and 15, the present invention provides a built-in cylindrical hood with throttle block, which is composed of an embedded tube 1, an outer sleeve 2 and a throttle block 3. The inline pipe 1 is a straight pipe section with uniform inner diameter and openings at both ends. The outer wall is provided with an annular support protrusion 13. The lower end of the outer casing 2 is open. The side wall of the outer casing 2 is provided with a through hole 22. The throttling block 3 is the center. Finishing a circular plate with a throttle hole 32; the throttle block 3 is fully welded to the upper opening of the inner tube 1, the outer tube 2 is buckled coaxially outside the inner tube 1, and a circular seam is defined between the two 12. The bottom end of the outer casing 2 is spot-welded with the support protrusion 13 on the outer wall of the embedded pipe 1. The position of the support protrusion 13 can form a baffle connected with the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com