Dedusting and desulfurizing fluid bed reactor with combined action of sound and magnetism

A technology of fluidized bed reactor and combined action, applied in the direction of energy-applied chemical/physical/physical chemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low desulfurization efficiency and particulate matter pollution, and achieve easy Capture and removal, large surface area, accelerated agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

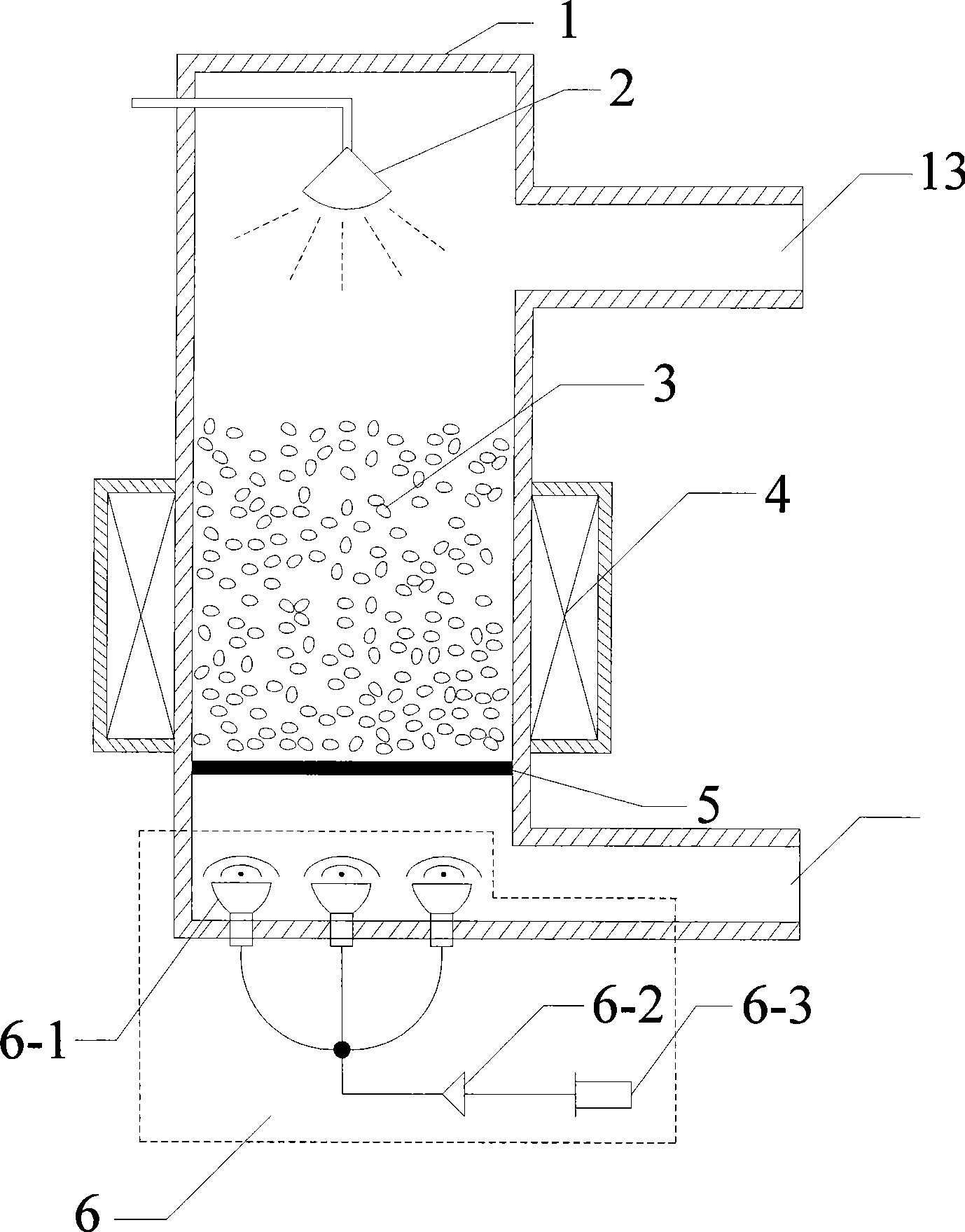

[0010] Specific embodiment one: dust removal and desulfurization fluidized bed reactor with combined action of sound and magnetism, the flue gas desulfurization reactor includes a fluidized bed, an atomizing nozzle 2, a magnetic helical coil 4 and an acoustic wave generating device 6; the flow The chemical bed is composed of a cylinder 1, an air distribution plate 5 and a magnetic bed material 3; the sound wave generating device 6 includes a signal generator 6-3, a signal amplifier 6-2 and a loudspeaker 6-1; There is a flue gas inlet 12, and the upper part of the right side wall of the cylinder body 1 is provided with a flue gas outlet 13, and the air distribution plate 5 is fixed in the horizontal direction inside the cylinder body 1, and the cylinder body 1 is equipped with a magnetic bed material 3, and the magnetic bed material 3 is distributed above the air distribution plate 5, and the outer wall of the cylinder 1 is wound with a magnetic helical coil 4, the position of t...

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and the dedusting and desulfurization fluidized bed reactor with combined acoustic and magnetic effects described in Embodiment 1 is that there are multiple speakers (6-1).

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and the dust removal and desulfurization fluidized bed reactor with combined acoustic and magnetic effects described in Embodiment 1 is that both the cylinder body 1 and the air distribution plate 5 are made of non-magnetic materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com