Gas-solid fluidized bed reactor with high inflation rate, method for realizing high inflation rate of fluidized bed and applications of gas-solid fluidized bed reactor and method

A fluidized bed reactor, aeration rate technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problem that the fluidization performance of the reactor has not made substantial progress, and achieve the effect of increasing the gas-solid reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand a gas-solid fluidized-bed reactor with a high aeration rate of the present invention, the following examples are used for illustration.

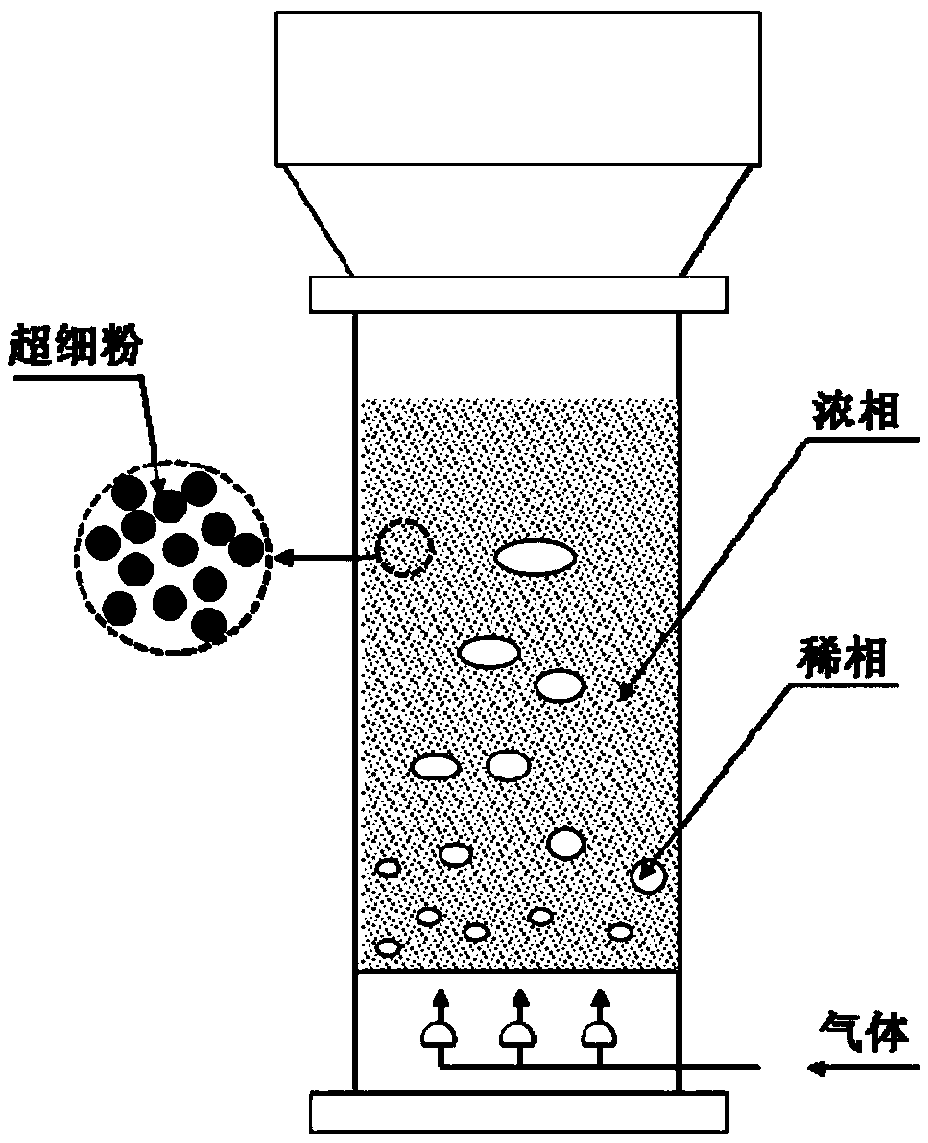

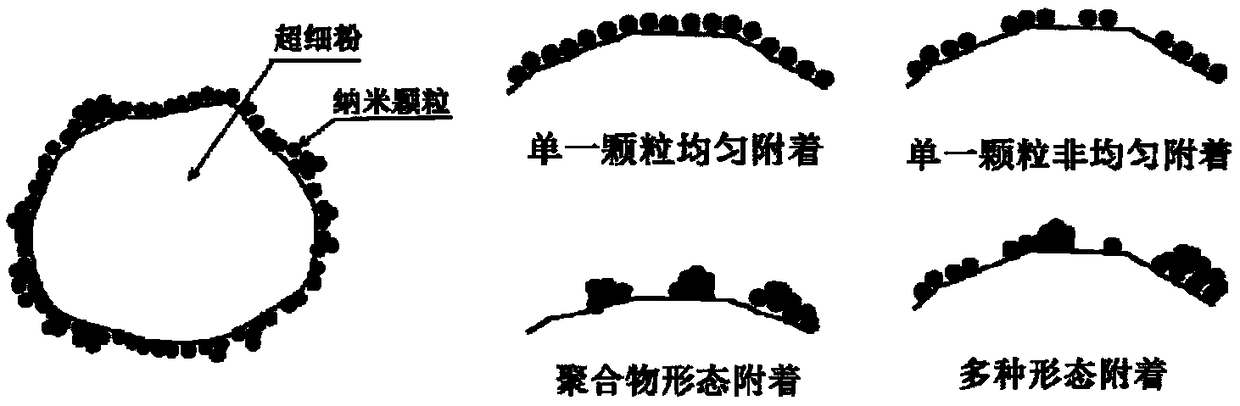

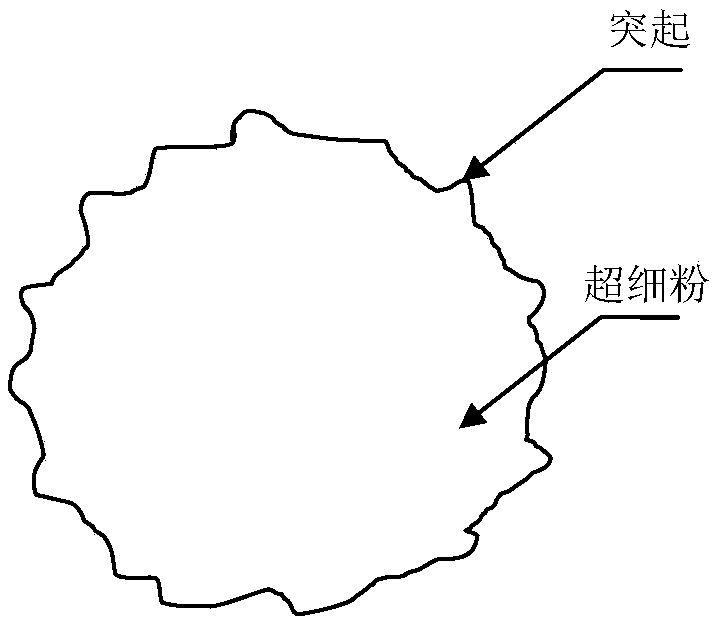

[0027] In one embodiment, the present invention discloses a gas-solid fluidized bed reactor with high gas filling rate, such as figure 1 As shown, it includes a cylindrical reactor shell perpendicular to the ground, a two-phase separator located in the upper part of the shell, and a gas distributor located in the bottom of the shell. The gas distributor can use any structure that can make the gas distribution relatively uniform, such as porous plate type, microporous plate type, blister type, multi-tube type, membrane type, packing, etc. Smaller spreader. In this embodiment, a perforated plate gas distributor is used, air is used as the fluidizing gas, and the particle density is selected to be 2500kg / m 3 , spherical glass beads with a particle diameter of 10 μm are used as ultrafine powder particles, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com