A New Type of Longitudinal Parallel Bed Adsorber

A bed adsorption, vertical technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of particle material wear, adsorber pressure drop, etc., to achieve low wear rate, reduce pressure loss, reduce wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

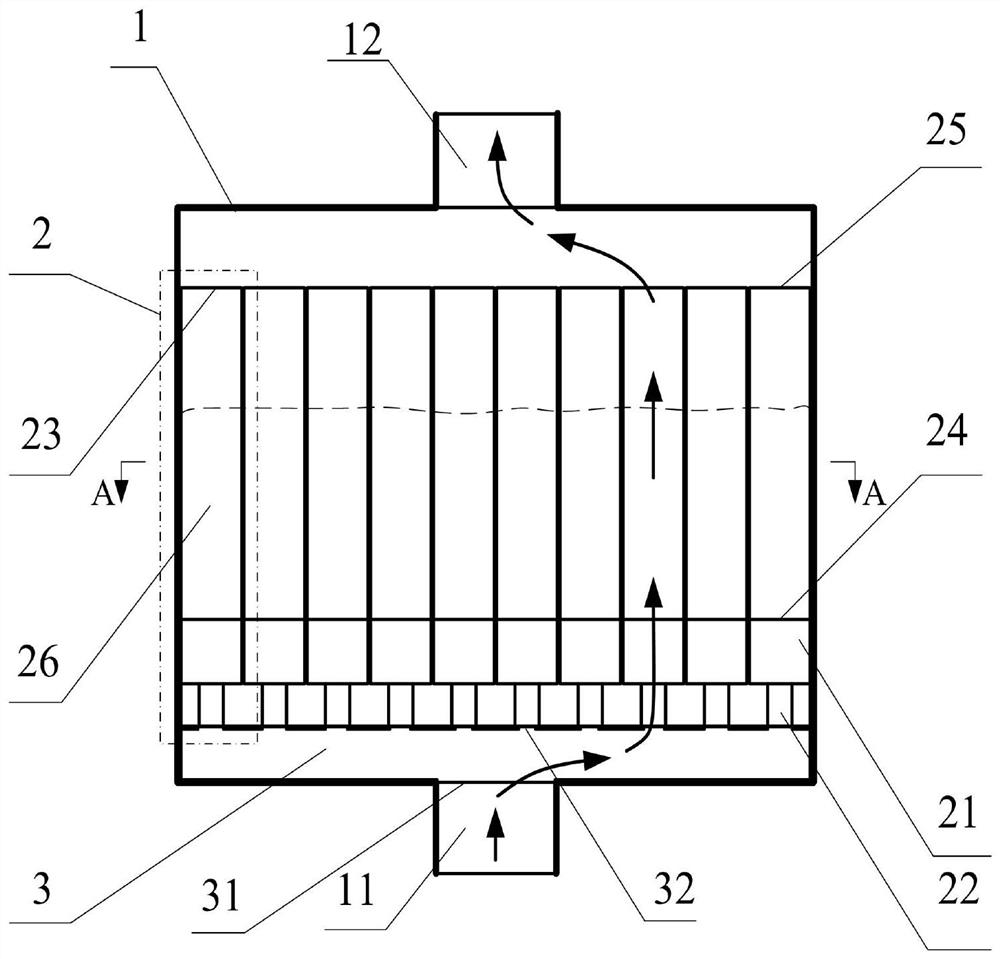

[0031] A new type of longitudinal parallel bed adsorber, such as Figure 1 to Figure 3 As shown, a housing 1, at least two fluidized beds 2 and a gas distributor 3 are included.

[0032] refer to figure 1 , the housing 1 is mainly used for installation and support. The housing 1 is provided with an air inlet 11 and an air outlet 12. The housing 1 can be supported by a bracket to facilitate connection at the air inlet 11. The shape of the housing 1 is not limited. Recommended according to The shape obtained by the arrangement of the fluidized bed 2 is designed.

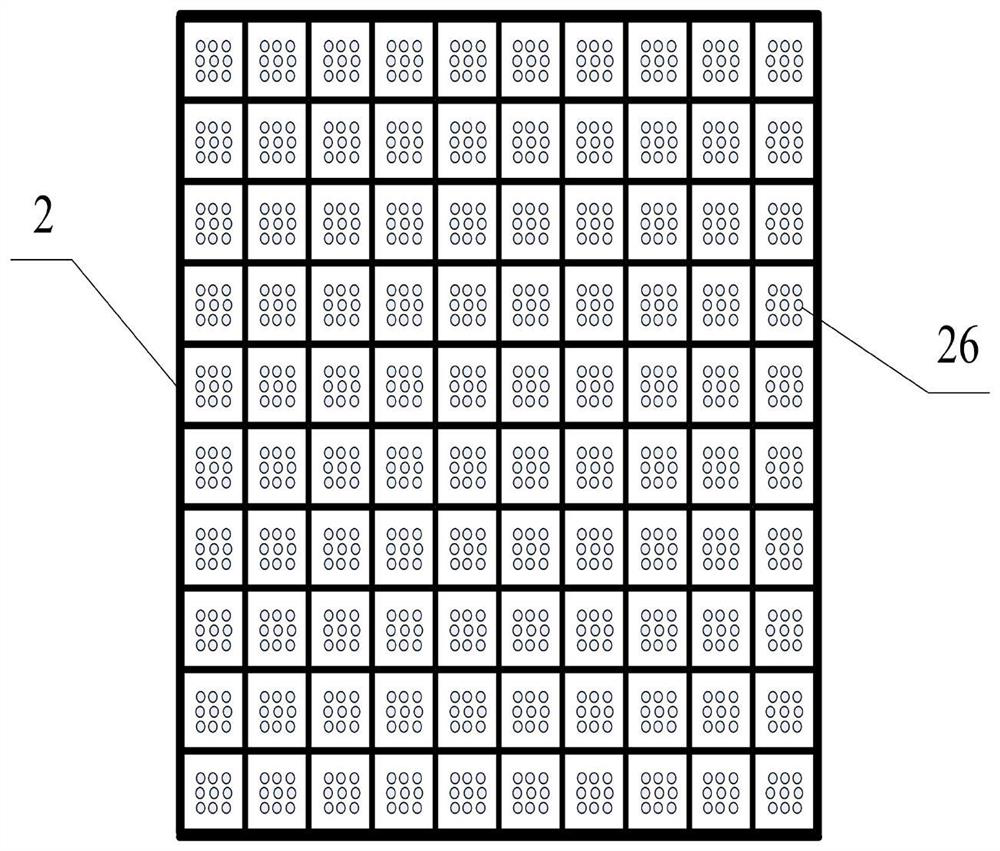

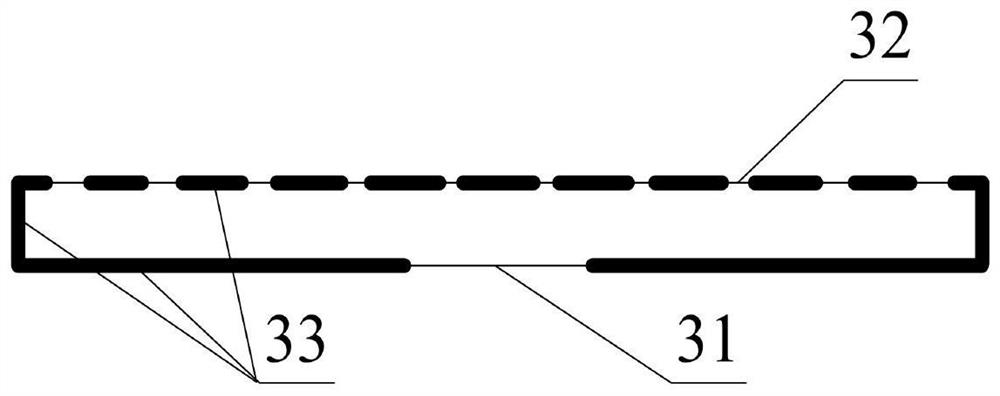

[0033] refer to figure 1 with figure 2 , a plurality of fluidized beds 2 are arranged in the shell 1, the fluidized beds 2 are arranged mutually and the adjacent air chambers 21 are independent from each other, the shapes and volumes of the fluidized beds 2 are the same, and the cross section of the shell 1 is square, The centers of the plurality of fluidized beds 2 are at the same height. The bottom of the fluid...

Embodiment 2

[0037] Different from Example 1, as Figure 4As shown, in this embodiment, the cross-sectional shape of the fluidized bed 2 is a regular hexagon.

Embodiment 3

[0039] Different from Example 1, as Figure 5 As shown, in this embodiment, the cross-sectional shape of the fluidized bed 2 is circular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com