A kind of leaching method of waste lithium ion battery cathode active material

A positive electrode active material and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve problems such as impact rate, high energy consumption, and high setting temperature, and achieve the effects of reducing corrosion, increasing leaching rate, and shortening leaching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

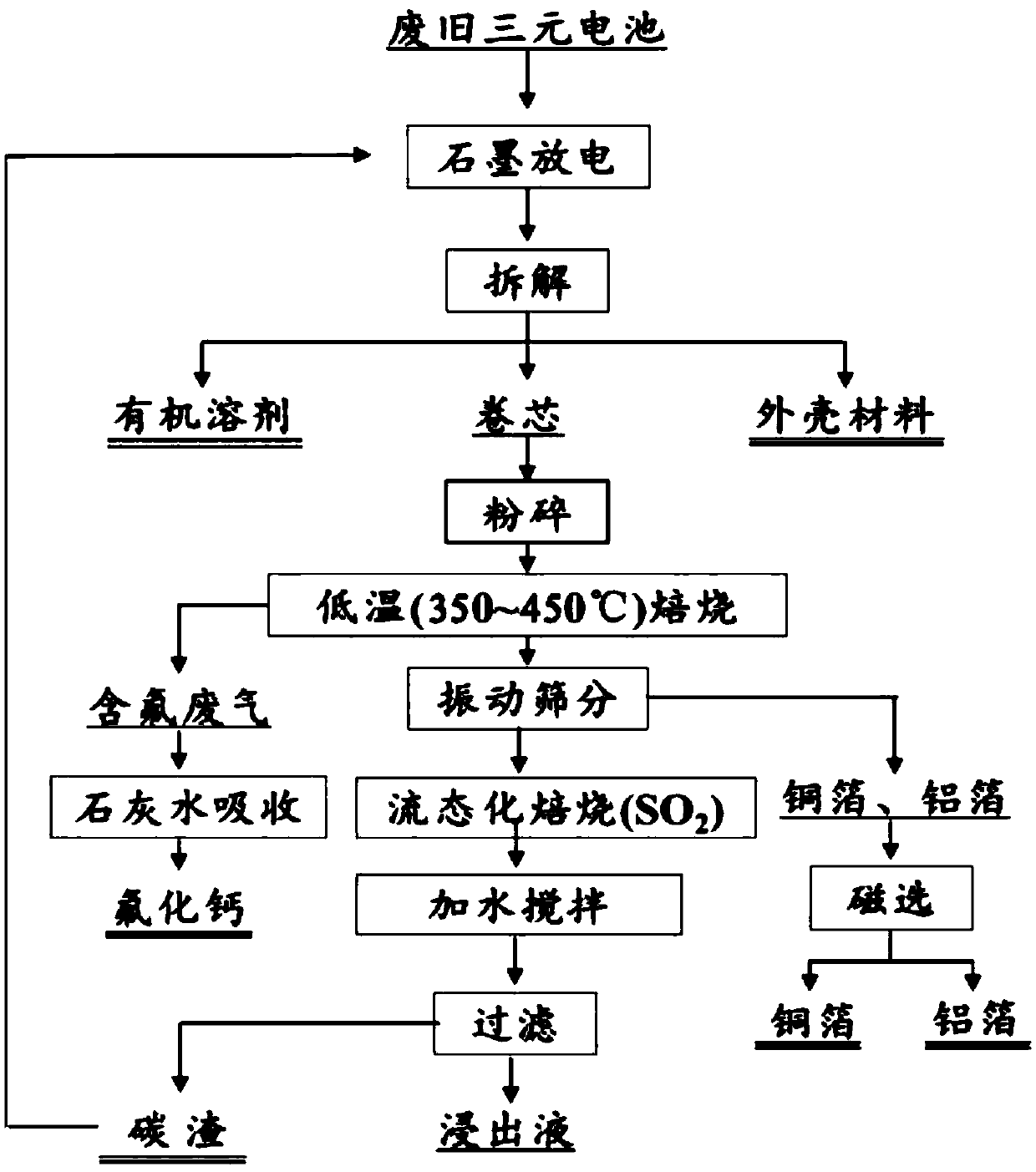

[0038] Take some lithium cobalt oxide batteries for used mobile phones, put them into the powder containing waste carbon slag and discharge them, pick them up when the voltage is lower than 1V, cut off the shell, drain the remaining electrolyte, and take out the winding core. Preliminarily crush the winding core, put it into a roasting furnace and heat it to 400°C, burn off the binder on the electrode piece and most of the negative electrode carbon material in the air atmosphere, and absorb the tail gas with a lime solution. The sintered solid mixture is taken out and sieved, the copper foil and aluminum foil fragments are on the sieve, and the cathode active material containing lithium cobalt oxide is mainly on the under sieve.

Embodiment 2

[0040] Get 20g embodiment 1 gained under-sieve product, pack into fluidized roasting furnace, pass into sulfur dioxide gas with the speed of 30L / h, tail gas uses NaHCO 3 Alkaline absorption. After the atmosphere was stabilized, the temperature was raised to 300°C at a rate of 10°C / min, and the solid particles were suspended in the furnace, and kept for 1.5 hours. After cooling to room temperature, take it out, add an appropriate amount of deionized water, and continue stirring for 20 minutes. The stirred cloudy solution was filtered to obtain a clear filtrate. After sampling and evaporating to dryness, X-ray diffractometer and atomic emission spectrometer detect that the main components of the filtrate are cobalt sulfate and lithium sulfate, and the content of cobalt element accounts for about 87% of the standard Co content of the original waste battery; the main component of the filter residue is carbon 1. Lithium cobaltate, wherein the content of cobalt element accounts fo...

Embodiment 3

[0042] Get 20g embodiment 1 gained under-sieve product, pack into fluidized roasting furnace, pass into sulfur dioxide gas with the speed of 30L / h, tail gas uses NaHCO 3 Alkaline absorption. After the atmosphere was stabilized, the temperature was raised to 350°C at a rate of 10°C / min, and the solid particles were suspended in the furnace, and kept for 1.5 hours. After cooling to room temperature, take it out, add an appropriate amount of deionized water, and continue stirring for 35 minutes. The stirred cloudy solution was filtered to obtain a clear filtrate. After the sample was evaporated to dryness, X-ray diffractometer and atomic emission spectrometer detected that the main components of the filtrate were cobalt sulfate and lithium sulfate, and the content of cobalt element accounted for 98.3% of the standard Co content of the original waste battery; the main component of the filter residue was carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com