Circulating fluid bed flue gas desulfurization tower

A circulating fluidized bed and desulfurization tower technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of uneven distribution of particle flow field, increase the resistance of desulfurization tower, affect the desulfurization efficiency, etc., to increase Arrangement of feed inlet, increasing gas-solid mixing intensity, and improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

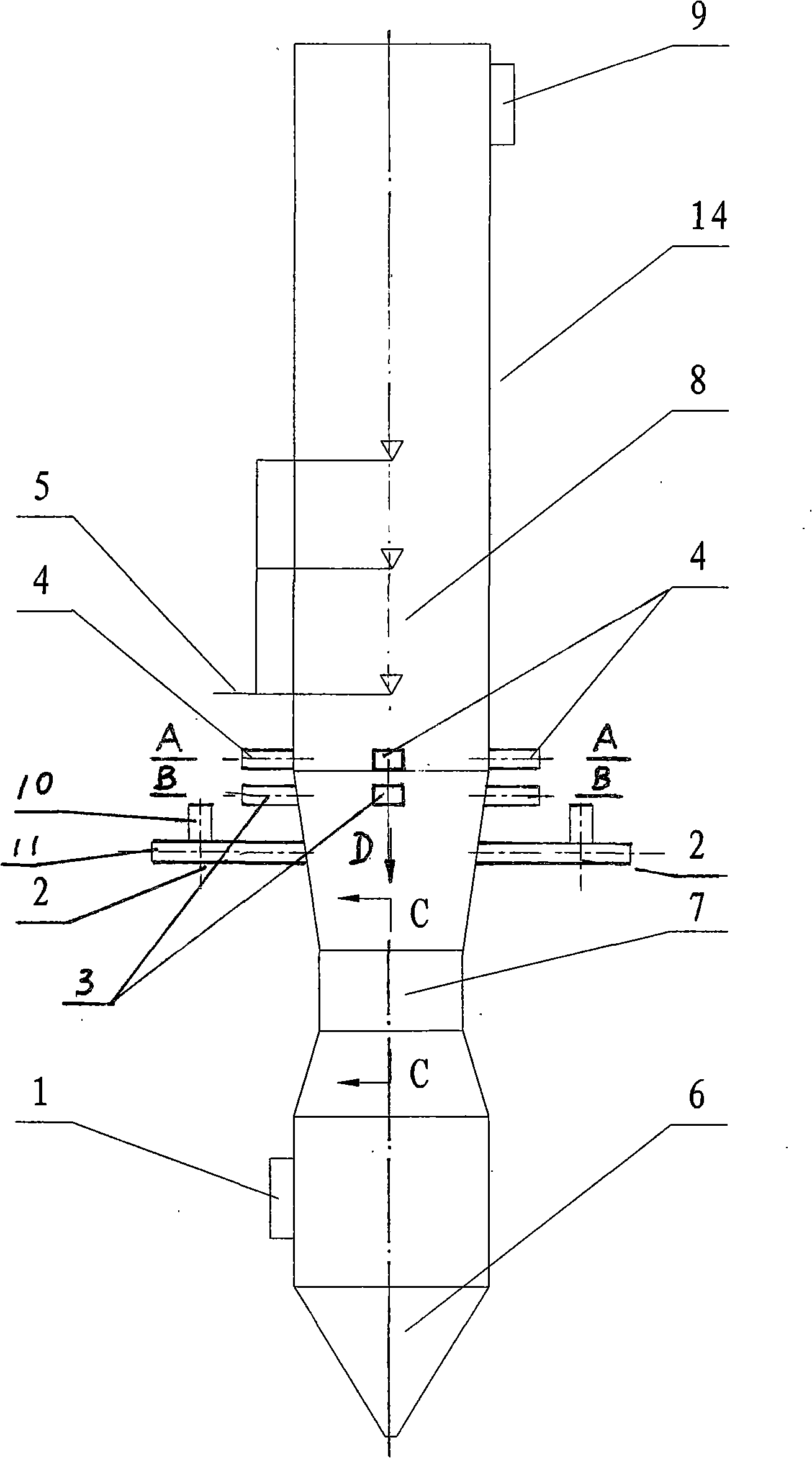

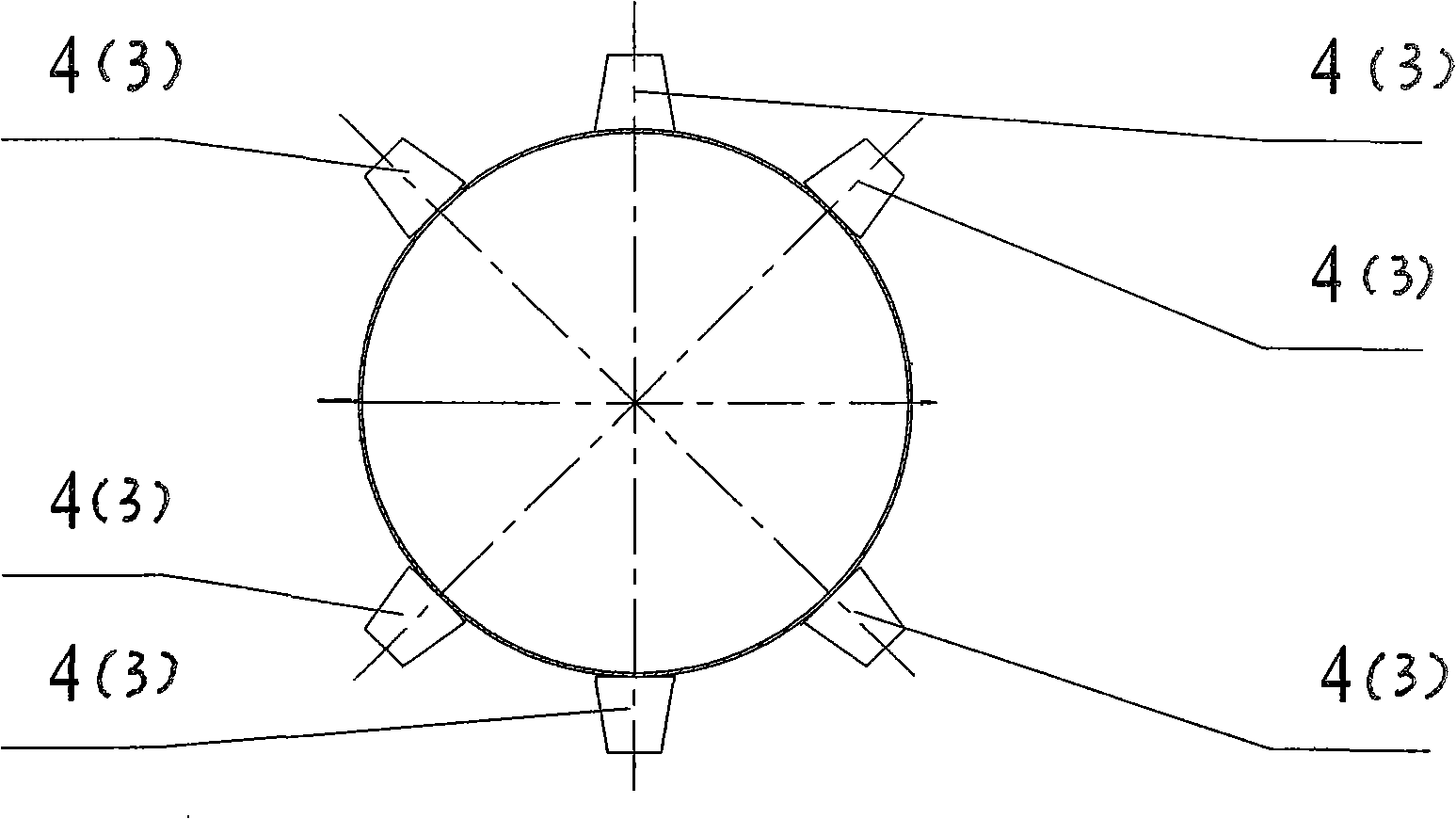

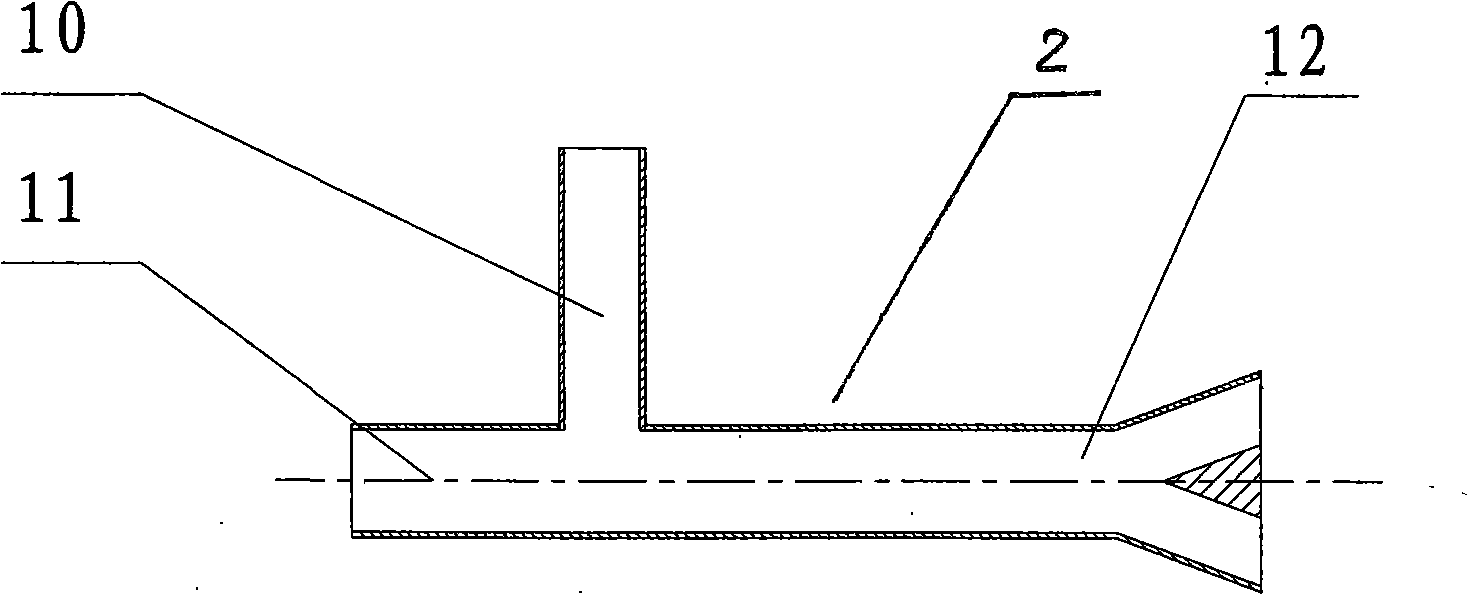

[0021] refer to Figure 1~5 , a circulating fluidized bed flue gas desulfurization tower of the present invention has a straight cylinder 8, a venturi throat cylinder 7 and a conical ash hopper 6 arranged in sequence from top to bottom to form a tower body 14 of an integral structure. On the side wall of the upper end of the straight cylinder 8 of the tower body 14 is provided a purified flue gas outlet 9 . The side wall of the straight cylinder 8 of the tower body 14 is provided with an atomized water injection device 5, and the nozzle of the atomized water injection device adopts a gas-liquid two-phase flow atomizing nozzle, and the atomized water injection device 5 is divided into two parts along the height direction. Three-layer injection, the present invention adopts three-layer structure. Below the atomized water injection device 5, on the side wall of the straight tube 8 of the tower body 14, a recirculation ash nozzle 4 is provided. On the side wall of the straight t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com