Fluidized bed capable of organizing ultrafine particles to be mixed in orderly manner

A technology of ultra-fine particles and fluidized bed, which is applied in the direction of mixing method, gas/steam and solid mixing, chemical instruments and methods, etc. It can solve the problems of particle back-mixing and unfavorable particle mixing in the bed, and achieve the suppression of particle back-mixing , Improve the uniformity, improve the effect of gas-solid contact efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

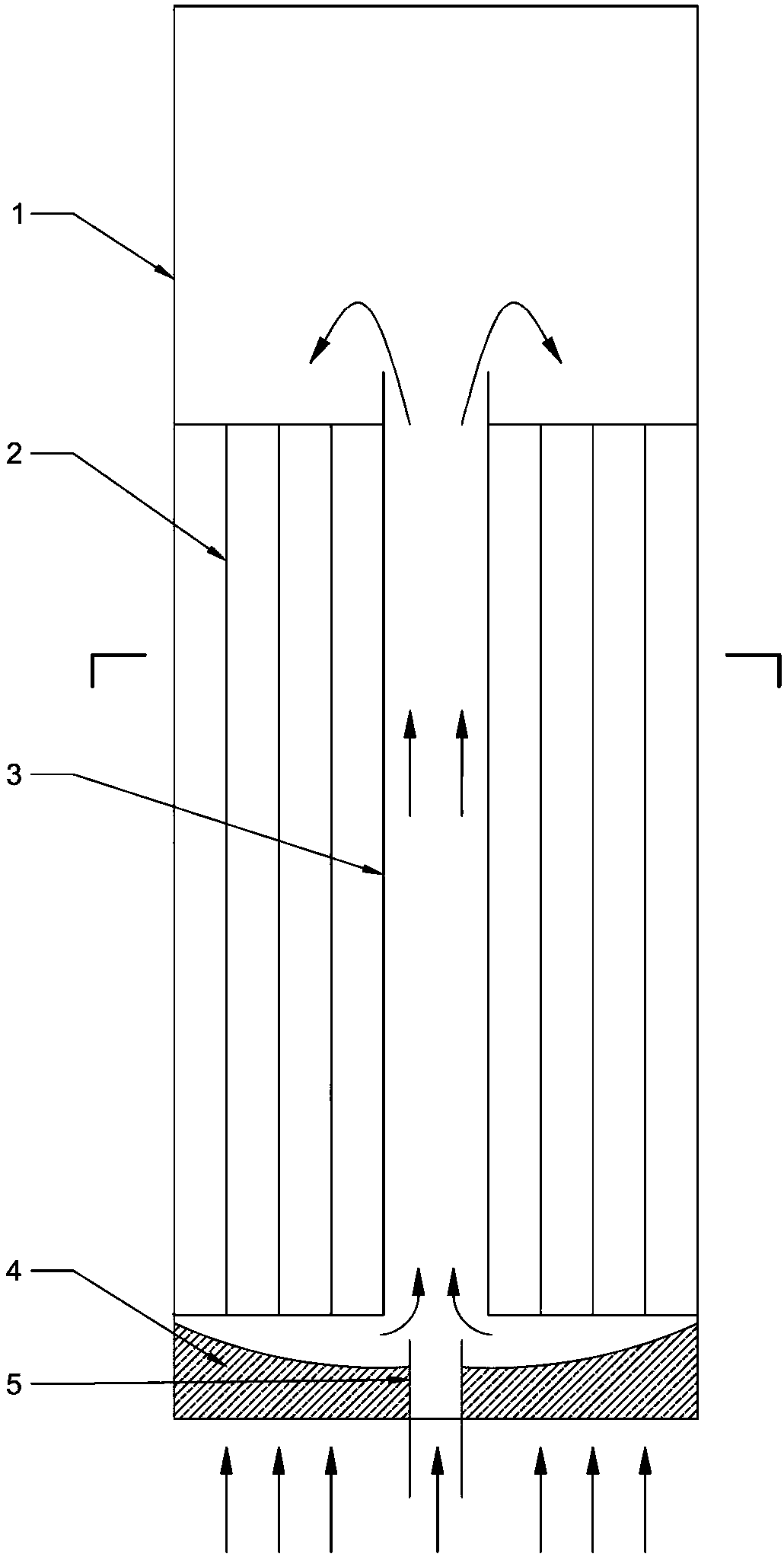

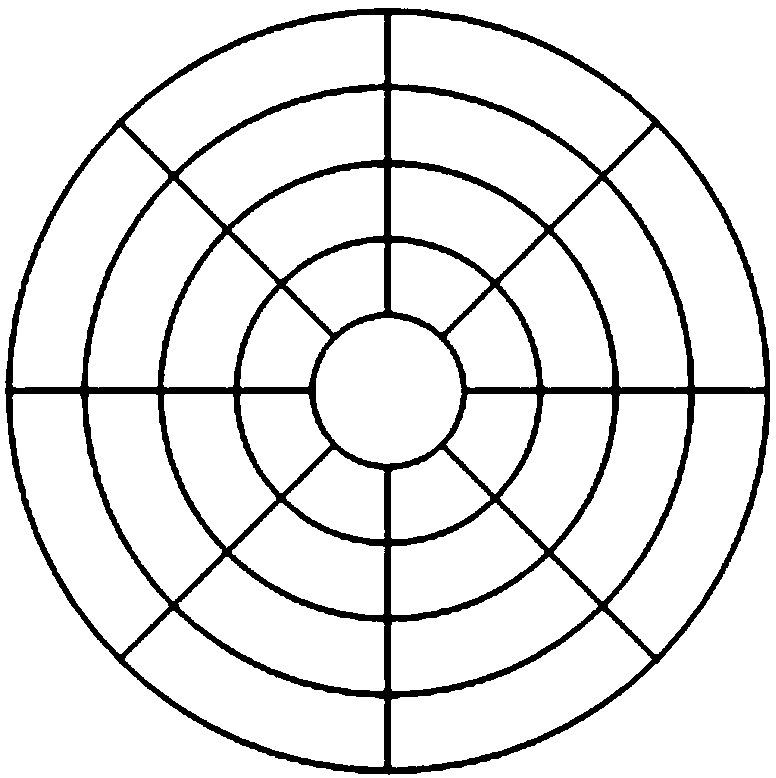

[0023] figure 1 It is a structural schematic diagram of a fluidized bed mixed with ordered ultrafine particles of the present invention, including an outer cylinder 1, a grid baffle plate 2, a guide tube 3, an air distribution plate 4, a central jet tube 5, etc., and a guide tube 3 Arranged in the middle of the outer cylinder 1, the grid baffle 2 is arranged in the annular area 2 between the draft pipe 3 and the outer cylinder 1, and the air distribution plate 4 is arranged on the draft pipe 3 and the grid baffle 2 Below, the central jet tube 5 is arranged in the middle of the air distribution plate 4 and corresponds to the draft tube 3 .

[0024] The basic idea of the present invention is to use a new type of internal member of ultra-fine particle flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com