Two-pore zeolite microsphere and preparation method thereof

A technology of microspheres and zeolites, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of adsorption of organic macromolecules or biomacromolecules, increase of device head loss, Due to problems such as limitations in the application field, it achieves the effects of not easy water loss, high adsorption and exchange capacity, and easy fluidization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Fly ash pretreatment: Take 50g of industrial fly ash in water, remove lumps and suspended slag, wash with water to remove accumulated adsorbate, filter, dry and grind at 105°C, pass through a 200-mesh sieve, get the product A , placed in a desiccator for later use.

[0028] Step 2: Setting of muffle furnace sintering curve: the first section is to heat up from 0-200°C for 5 minutes, the second section is to heat up from 200-550°C for 10 minutes, the third section is to heat up from 550-950°C for 10 minutes, and the fourth section is to heat up from 550-950°C for 10 minutes. The first stage is to heat up from 950-1150°C for 10 minutes, and the fifth stage is to keep warm at 1150°C for 10 minutes.

[0029] Step 3: Pick up the product A 24g, coal powder 8g, Fe 2 o 3 2g, Na 2 CO 3 1g and 24ml of water, mix thoroughly. The mixed sample is hand-made into balls with a diameter of 5-8 mm, placed in a muffle furnace, and roasted into ultra-light fly ash balls ac...

Embodiment 2

[0035] 1. Build the reactor: The reactor is made of plexiglass, with a diameter of 60 mm and a column height of 700 mm. There is a sampling hole. Compressed air enters the reactor from the bottom through the aeration diffuser, and the aeration is adjusted with an air flow meter. Quantity, using downward flow into the water, gas-water reverse contact reaction.

[0036] 2. Configure test water: use artificial water distribution, and the mass concentration of COD in the simulated test water is 126~316 mg / L, NH 4 + The mass concentration of -N is 45-77 mg / L, and the pH is 7.2-8.0.

[0037] 3. Enrichment culture and fixation of nitrifying bacteria liquid: the ultra-slight mesoporous zeolite microspheres in Example 1 are subjected to high-temperature sterilization, according to the literature (Yang Hongyan, Long Xiujuan, Li Qinghua. Nitrifying bacteria enrichment culture and treatment of eutrophication Research on the application of chemical water. Environmental Protection Science...

Embodiment 3

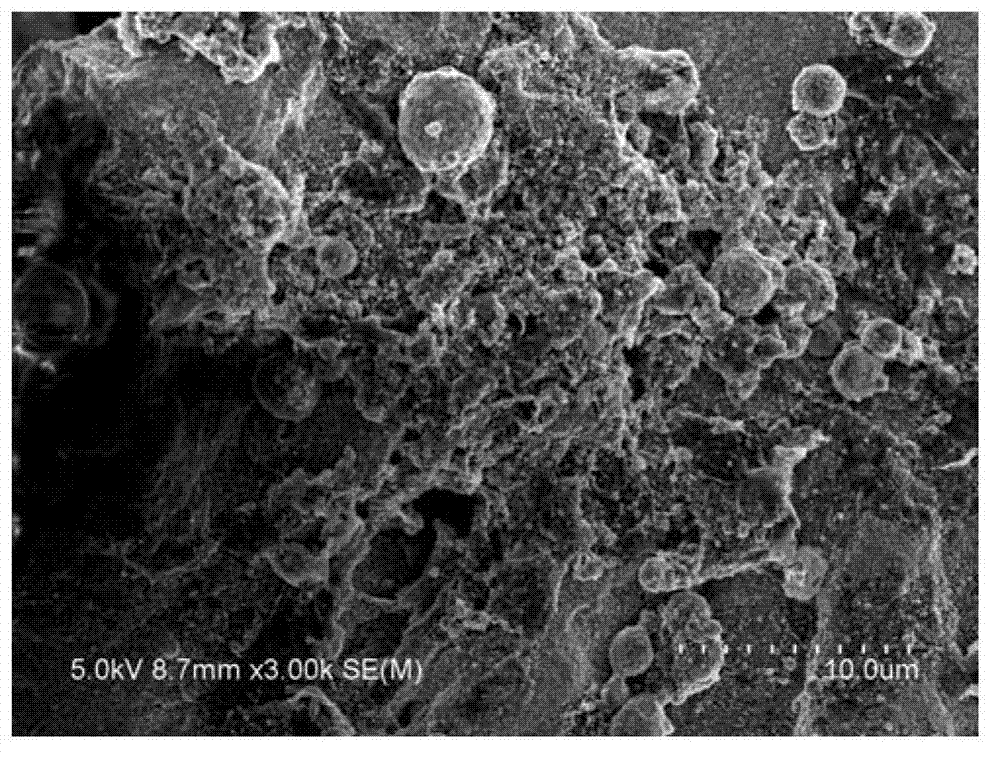

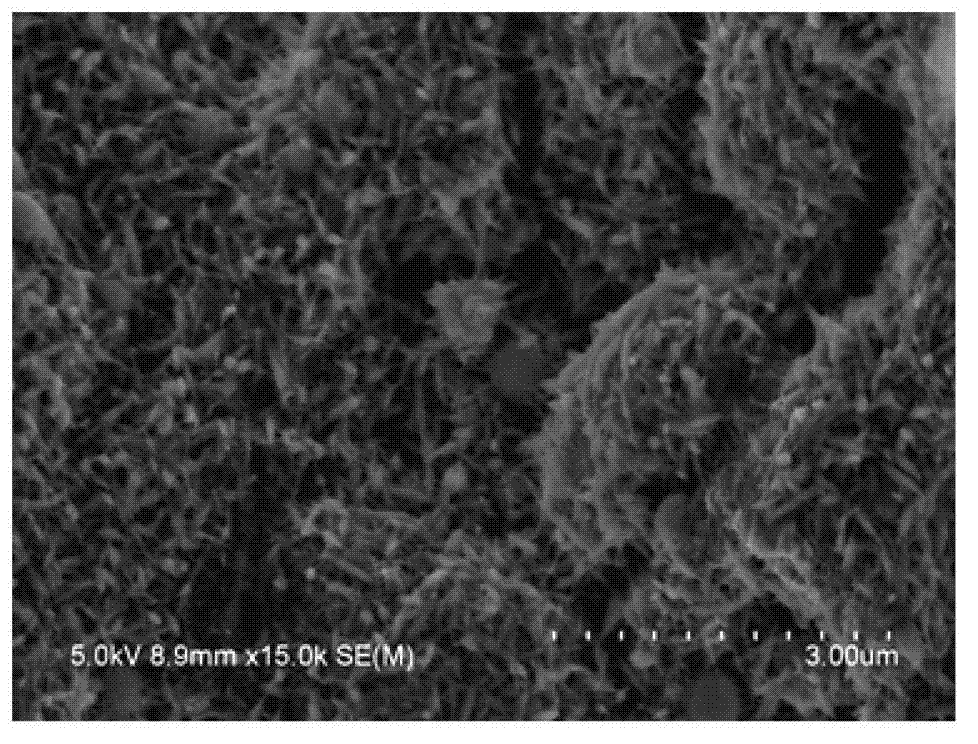

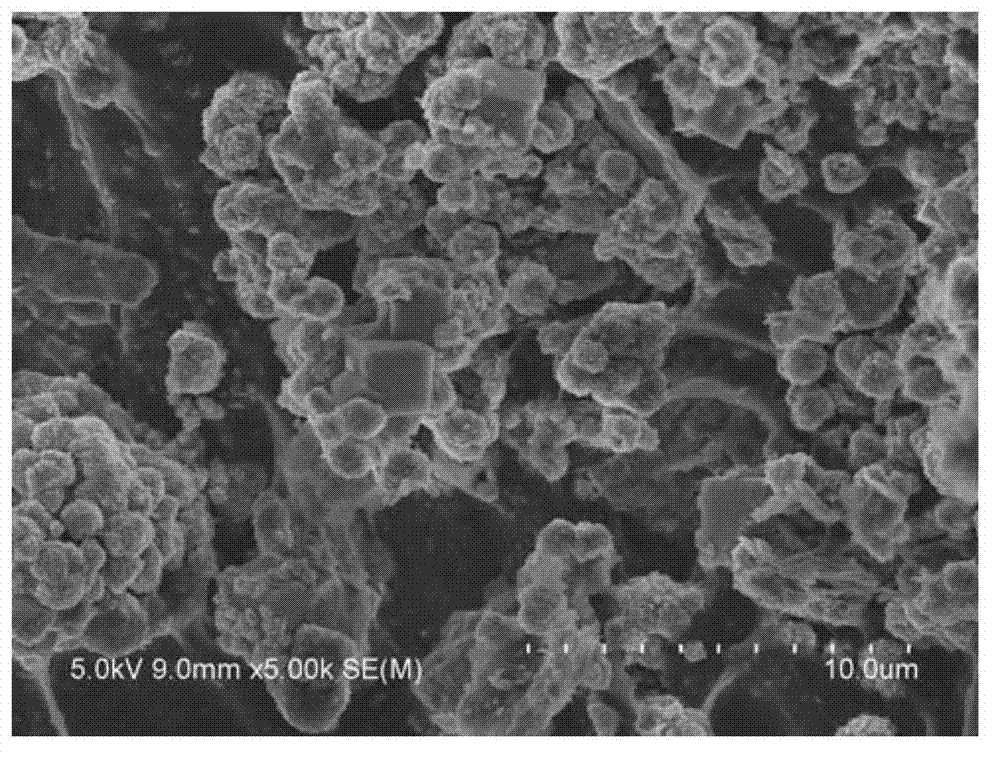

[0040] The performance detection of the material made in embodiment 1 is as follows:

[0041] 1. For the test method of physical properties (bulk density, water absorption) of zeolite balls, please refer to the literature (CJ / T 299-2008 Artificial ceramsite filter material for water treatment [S]), the results show that the water absorption of Example 1 is 18- 24%, the bulk density is 610-630 kg∕m 3 ,

[0042] 2. For the test method of compressive strength of zeolite balls, please refer to the literature (Weng Huanxin, Zhang Jinjun, Cao Yansheng, etc. Performance characteristics and firing process of sludge ceramsite[J].Journal of Zhejiang University (Engineering Science Edition), 2011, 45(10) : 1077-1883.), the results show that: the compressive strength of Example 1 is ≥ 6Mpa,

[0043] 3. Specific surface test:

[0044] The microspheres prepared in Example 1 were pulverized with a pulverizer and then sieved with a 100-mesh sieve, placed in an electric heating constant tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com