Novel aerobiont fluidized bed reactor and technology thereof

A fluidized bed reactor, aerobic biological technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc. Problems such as poor aqueous and biological affinity, poor fluidization performance, etc., achieve the effect of small footprint, low operating cost, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

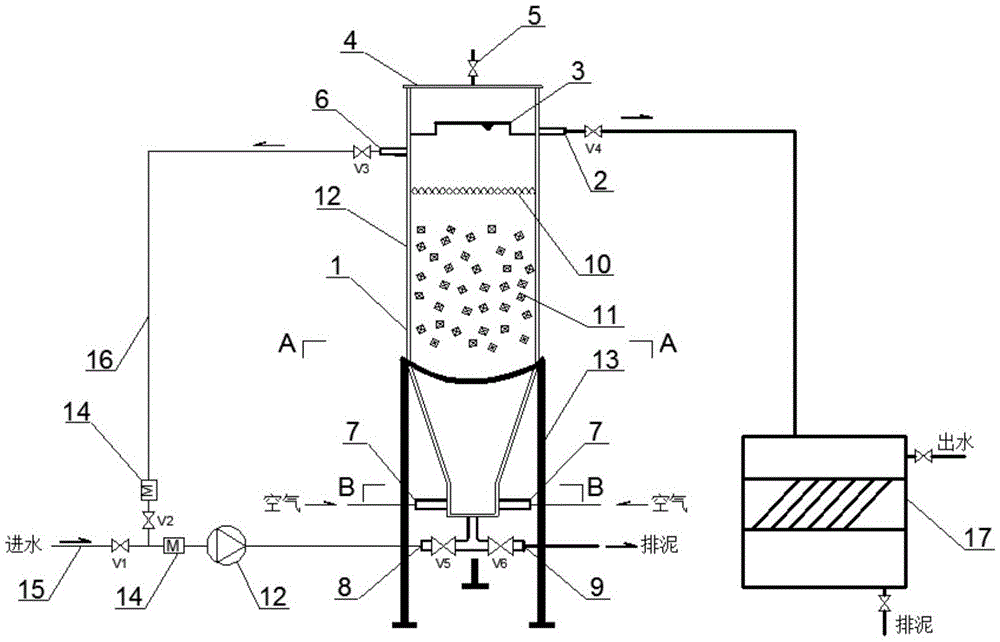

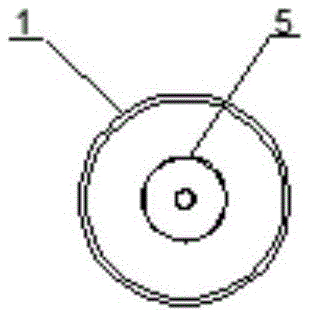

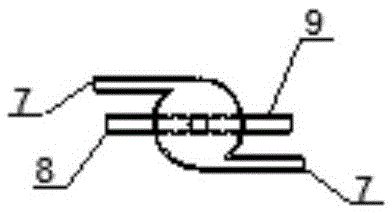

[0049] Such as Figure 1~3 As shown, a new type of aerobic biological fluidized bed reactor includes an outer support 13, a reactor tank 1, an external pump 12 and a slanted plate clarifier 17, the upper part of the reactor tank 1 is a cylinder, and the bottom is a circular platform , the middle and lower part of the reactor tank 1 is welded with the outer support 13,

[0050] The top of the reactor tank 1 is provided with a cover plate 4, and an exhaust valve 5 is provided on the outside of the cover plate 4, and a manhole is provided on the cover plate 4,

[0051] The upper side wall of the reactor tank 1 is provided with a water outlet 2, the upper part of the reactor tank 1 is provided with a water outlet weir 3, and the water outlet 2 is provided with a ball valve V 4 ,

[0052] The opposite side wall of the water outlet 2 of the reactor tank body 1 is provided with a backflow port 6, the height of the backflow port 6 is lower than the water outlet 220cm, and the backfl...

specific Embodiment 2

[0069] Such as Figure 1~3 As shown, a new type of aerobic biological fluidized bed reactor includes an outer support 13, a reactor tank 1, an external pump 12 and a slanted plate clarifier 17, the upper part of the reactor tank 1 is a cylinder, and the bottom is a circular platform , the middle and lower part of the reactor tank 1 is welded with the outer support 13,

[0070] The top of the reactor tank 1 is provided with a cover plate 4, and an exhaust valve 5 is provided on the outside of the cover plate 4, and a manhole is provided on the cover plate 4,

[0071] The upper side wall of the reactor tank 1 is provided with a water outlet 2, the upper part of the reactor tank 1 is provided with a water outlet weir 3, and the water outlet 2 is provided with a ball valve V 4 ,

[0072] The opposite side wall of the water outlet 2 of the reactor tank body 1 is provided with a backflow port 6, the height of the backflow port 6 is lower than the water outlet 250cm, the backflow p...

specific Embodiment 3

[0089] Such as Figure 1~3 As shown, a new type of aerobic biological fluidized bed reactor includes an outer support 13, a reactor tank 1, an external pump 12 and a slanted plate clarifier 17, the upper part of the reactor tank 1 is a cylinder, and the bottom is a circular platform , the middle and lower part of the reactor tank 1 is welded with the outer support 13,

[0090] The top of the reactor tank 1 is provided with a cover plate 4, and an exhaust valve 5 is provided on the outside of the cover plate 4, and a manhole is provided on the cover plate 4,

[0091] The upper side wall of the reactor tank 1 is provided with a water outlet 2, the upper part of the reactor tank 1 is provided with a water outlet weir 3, and the water outlet 2 is provided with a ball valve V 4 ,

[0092] The opposite side wall of the water outlet 2 of the reactor tank body 1 is provided with a return port 6, the height of the return port 6 is lower than the water outlet 235cm, and the return por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com