A kind of preparation method of lithium-sulfur battery cathode material

A positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of graphene edge defects, poor industrial production feasibility, expensive, etc., achieve small discharge capacity attenuation, improve battery life Effects of improving chemical properties and cycle stability

Inactive Publication Date: 2019-10-01

HEBEI UNIV OF TECH

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the above-mentioned existing technologies of graphene-sulfur composite cathode materials have improved the performance of lithium-sulfur batteries to a certain extent, they still have common defects: the effective loading of sulfur in the cathode material is low, and the "shuttle effect" of polysulfides Obviously, the volume expansion effect of lithium-sulfur batteries is significant, the electrochemical performance of the batteries is unstable, the material yield is low, and the feasibility of industrial production is poor

Although this prior art has improved the structural properties of graphene to a certain extent, there are still obvious defects: the materials involved in its preparation process are toxic and expensive, and cannot meet the requirements of environmental protection and industrial production. The graphene prepared by calcination has obvious edge defects, which cannot be applied to the preparation of cathode materials for lithium-sulfur batteries

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Login to View More

Abstract

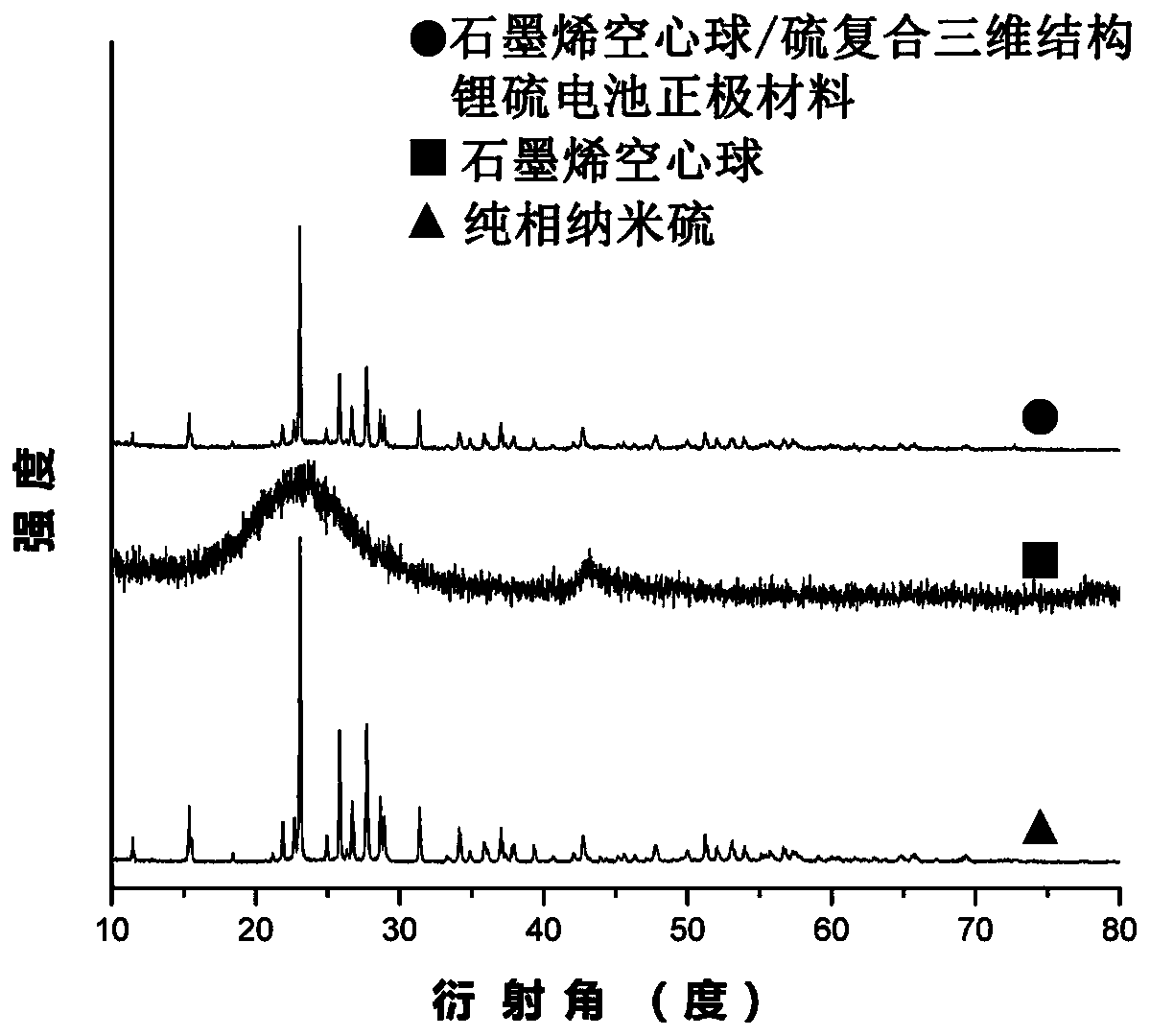

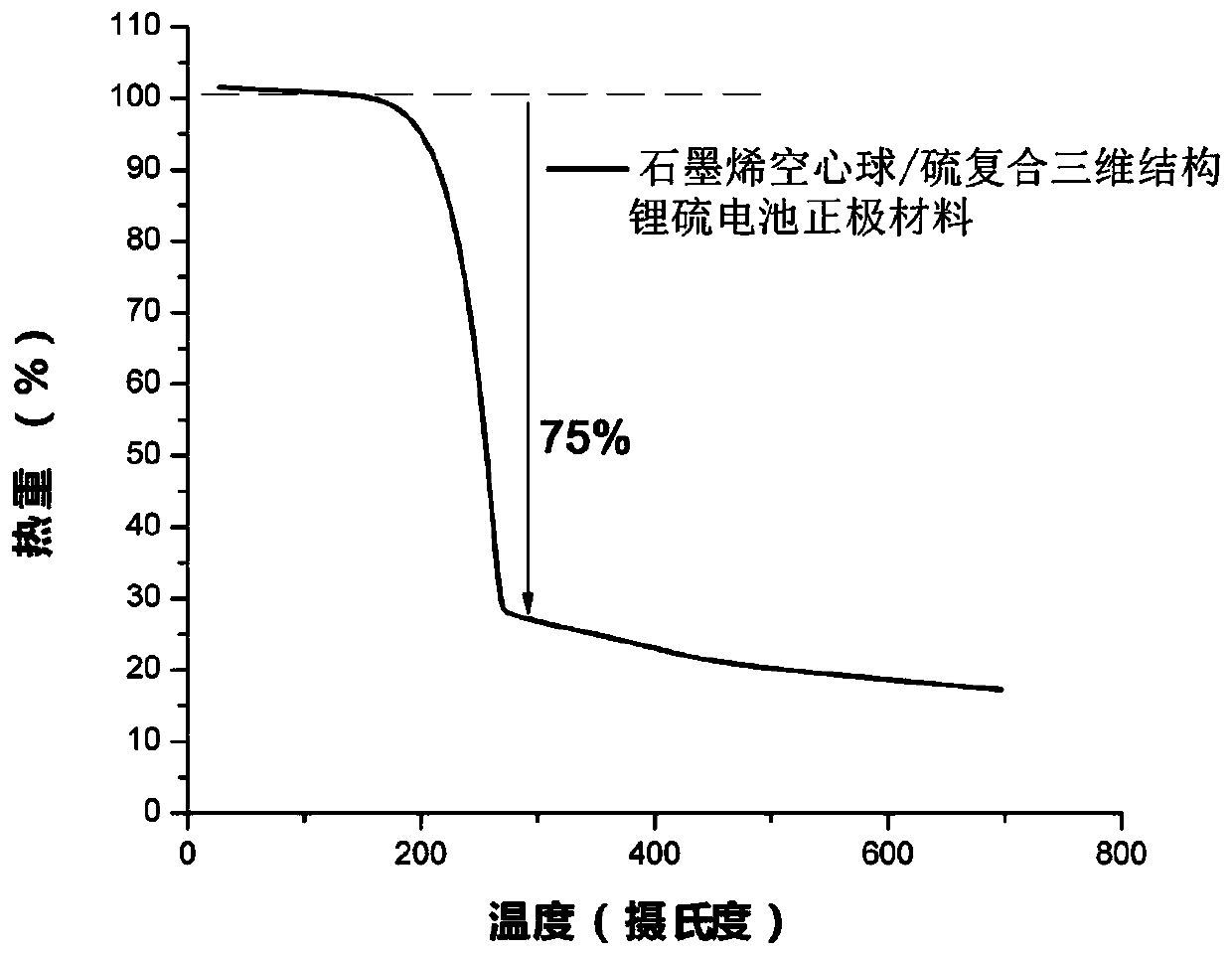

The invention relates to an electrode composed of active materials, in particular to a lithium-sulfur battery anode material preparation method. Graphene is structurally modified for preparing graphene hollow spheres by a template method and spray drying technology combined pore forming technology, and then ball milling and hot-melt sulfur doping processes are adopted for preparing a graphene hollow sphere-sulfur combined three-dimensional lithium-sulfur battery anode material. Defects of low effective sulfur loading quantity, evident polysulfide 'aero effect', evident lithium-sulfur battery volume expansion effect and battery electrochemical performance instability of lithium-sulfur battery anode materials prepared in the prior art are overcome.

Description

technical field The technical solution of the invention relates to an electrode composed of active materials, in particular to a preparation method of a cathode material for a lithium-sulfur battery. Background technique Lithium-ion battery is a new type of battery with environmental protection and high specific energy. Although the development of lithium-ion batteries is very mature, and its specific energy is very close to the theoretical specific energy of its corresponding materials (graphite anode is 300mAh / g), it still cannot satisfy people's growing demand for new batteries with environmentally friendly and high specific energy. The development of next-generation lithium secondary battery cathode materials with high energy density, environmental protection and low cost has become an urgent problem to be solved. As the most promising lithium secondary battery, the theoretical specific energy of the new lithium-sulfur battery is 2600Wh / kg, which is 5 times the theoreti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M4/36H01M4/38H01M4/62H01M10/052

CPCH01M4/362H01M4/38H01M4/62H01M4/625H01M4/628H01M10/052Y02E60/10

Inventor 李海鹏孙连城杨爽王卓刘雯刘斐然曹航畅

Owner HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com