Oscillating type propeller

A thruster and swing-type technology, which is applied in the direction of non-rotating propulsion elements, non-mechanical gear transmissions, ships, etc., can solve the problems that real-time online adjustment of propellers cannot be realized, and achieve intuitive and simple control operations, and improve Controllability, the effect of reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

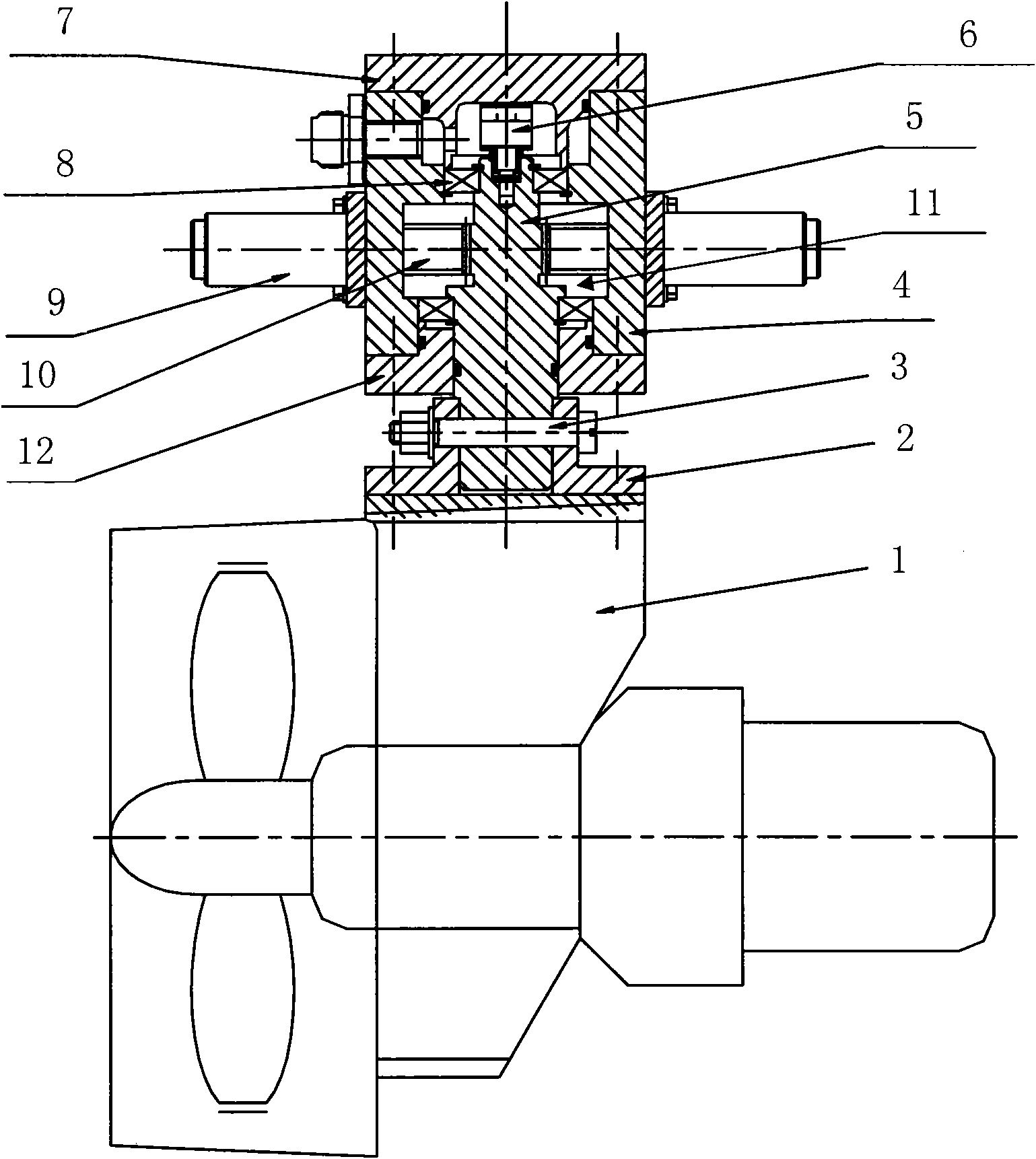

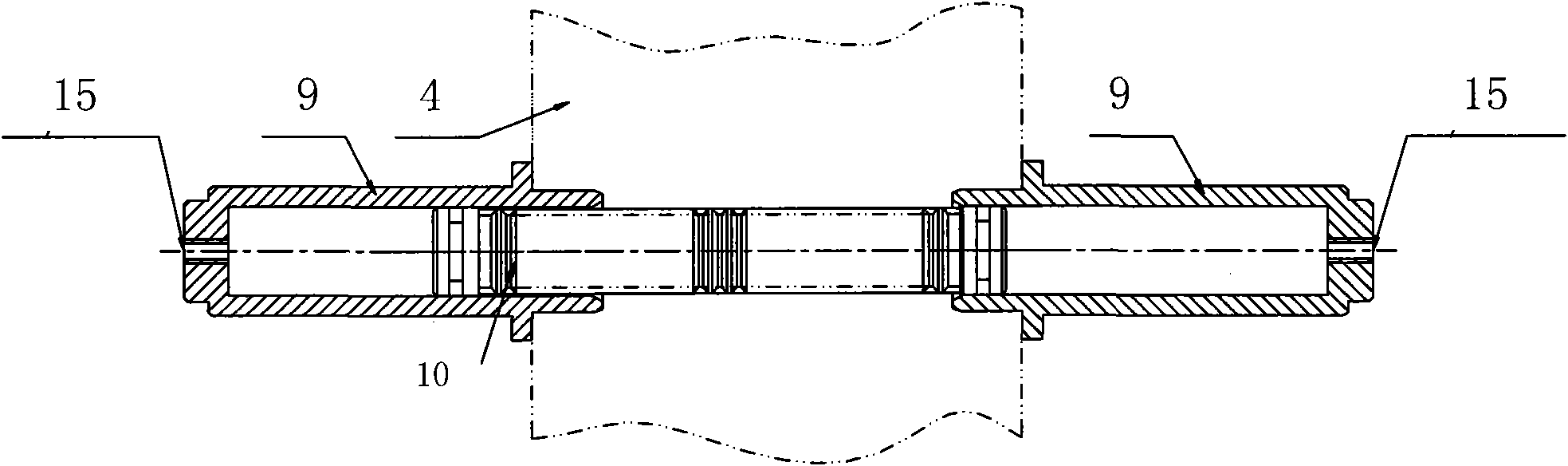

[0017] Embodiment 1: as figure 1 , figure 2 As shown, the present invention comprises propeller 1 and swing mechanism 13, and described swing mechanism 13 is connected with propeller 1 through the swing shaft 5 in it, makes the axis of swing shaft 5 perpendicular to the horizontal axis of propeller 1, and swing shaft The end structure of the propeller 1 connected with 5 matches with the connecting flange 2, and is connected and fixed through the connecting flange 2, and the swing shaft 5 and the connecting flange 2 are connected and fixed through the connecting bolt 3. Described swing mechanism 13 comprises box body 4, swing shaft 5, mounting flange 7, driving mechanism and end cover 12, and box body 4 one end is provided with mounting flange 7, and the other end is equipped with end cover 12, and swing shaft 5 is placed on Inside the box body 4 and extend out the end cover 12, the swing shaft 5 and the box body 4 are installed through the support bearing 8, the installation...

Embodiment 2

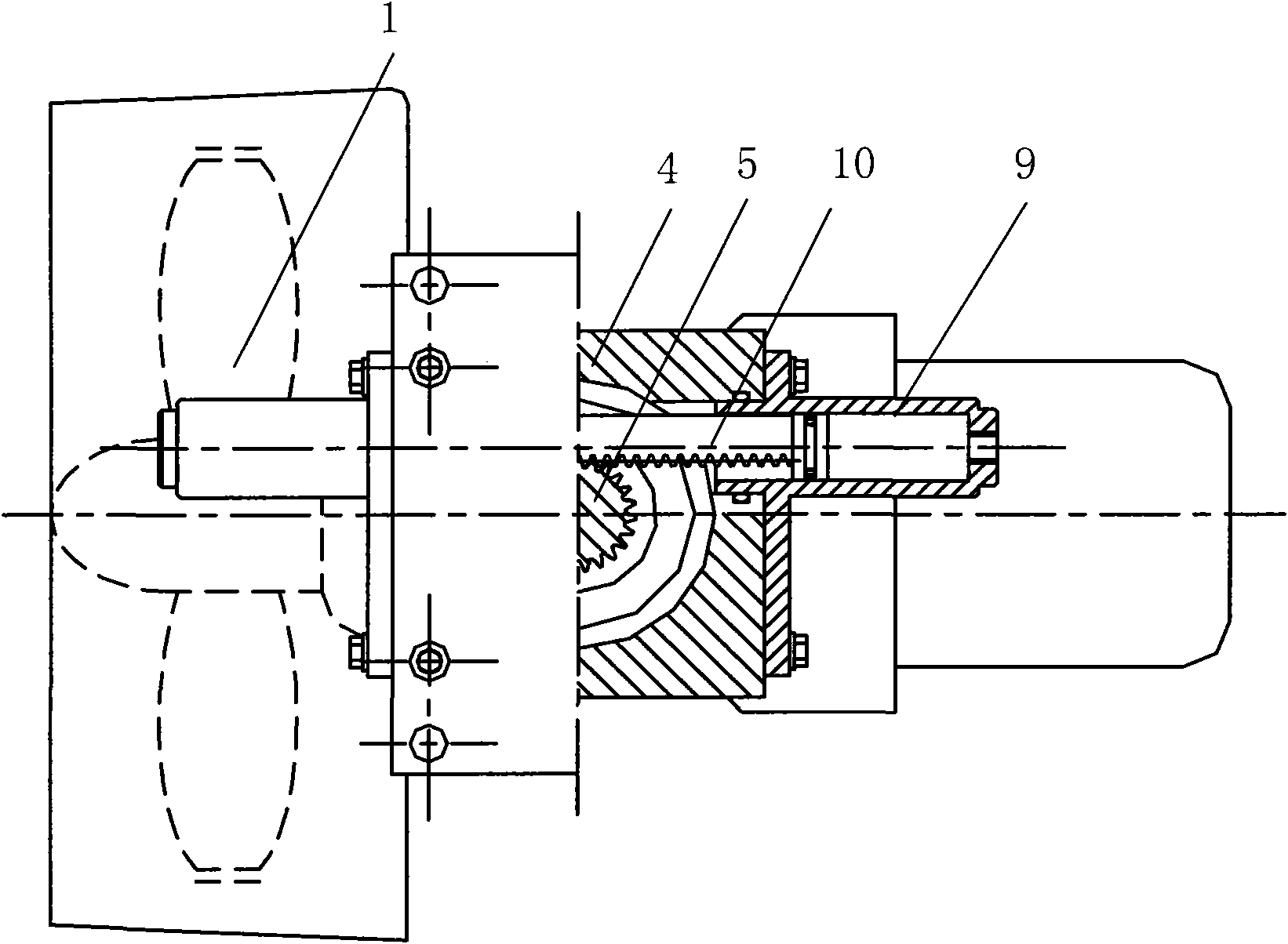

[0020] Embodiment 2: The overall structure of this example is the same as that of Embodiment 1, the difference is that: this example installs a gear 14 that matches the driving rack 10 on the swing shaft 5 . The drive rack 10 moves linearly under the push of the hydraulic oil, driving the swing shaft 5 and the propeller 1 to rotate to realize various working states, such as Figure 4 As shown, (a) is a schematic diagram of the front view of the forward and backward state; (b) is a schematic diagram of the front view of the side shift state after (a) is rotated 90 degrees; (c) is a schematic diagram of the top view of the forward and backward state; (d) is ( c) The top view schematic diagram of the heave state after rotating 90 degrees; (e) is the schematic diagram of the propeller rotating an angle A.

[0021] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com