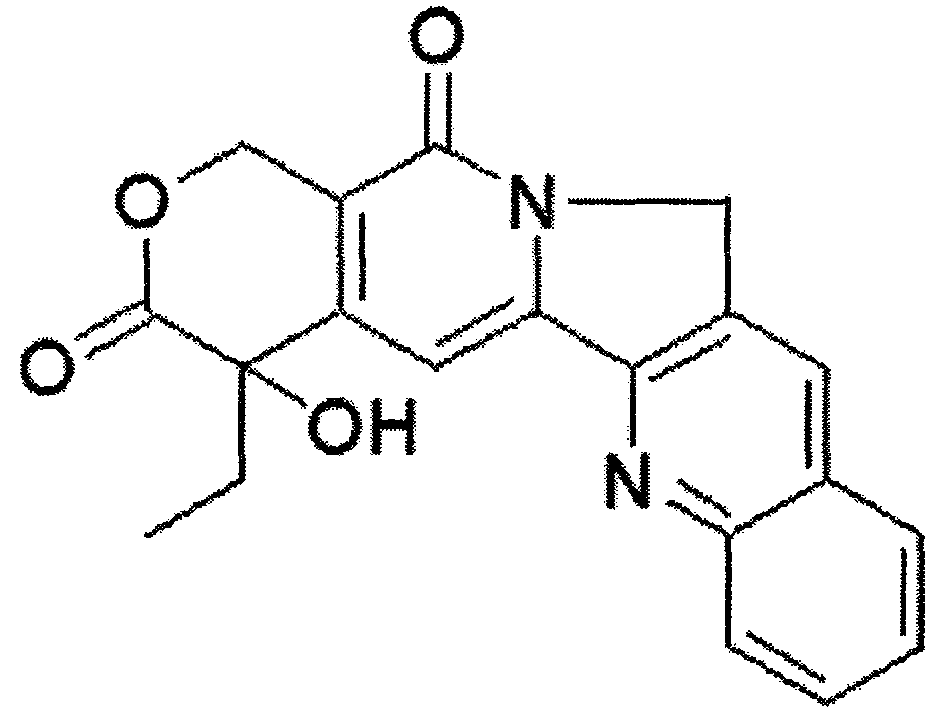

Camptothecin separation and purification method

A technology for separation, purification and camptothecin, applied in the direction of organic chemistry, can solve the problems of large consumption of organic solvents, poor economy, low selectivity, etc., and achieve the effect of reducing the content of impurities, increasing the service life, and reducing the number of crystallization times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for separating and purifying camptothecin, characterized in that it consists of the following steps:

[0034] 1) The camptothecin solution is passed through diatomaceous earth to remove impurities

[0035] 1.1) 500 g of commercially available camptothecin extract (containing 10% camptothecin) is cut into small pieces, placed in a 5L beaker, the ratio of solid to liquid is 1: 6 (g: mL), and 3 L of 65% ethanol was stirred and dissolved for 5 hours;

[0036] 1.2) spread diatomaceous earth evenly in the Buchner funnel, its thickness is 2cm;

[0037] 1.3) Filter the dissolved camptothecin solution with a Buchner funnel, remove solid impurities therein, etc., to obtain filtrate A for subsequent use; collect the filter residue and mix and dissolve the next batch of camptothecin extract for filtration;

[0038] 2) Membrane separator removes impurities from camptothecin solution

[0039] The filtrate A obtained in step 1) is passed through a membrane separator, and a...

Embodiment 2

[0053] A method for separating and purifying camptothecin, characterized in that it consists of the following steps:

[0054] 1) The camptothecin solution is passed through diatomaceous earth to remove impurities

[0055] 1.1) 300g of commercially available camptothecin extract (containing 10% camptothecin) is cut into small pieces, placed in a 5L beaker, the ratio of solid to liquid is 1: 10 (g: mL), and 3 L of 95% ethanol was stirred and dissolved for 5 hours;

[0056] 1.2) spread diatomaceous earth evenly in the Buchner funnel, its thickness is 2cm;

[0057] 1.3) Filter the dissolved camptothecin solution with a Buchner funnel, remove solid impurities therein, etc., to obtain filtrate A for subsequent use; collect the filter residue and mix and dissolve the next batch of camptothecin extract for filtration;

[0058] 2) Membrane separator removes impurities from camptothecin solution

[0059] The filtrate A obtained in step 1) is passed through a membrane separator, and a...

Embodiment 3

[0073] A method for separating and purifying camptothecin, characterized in that it consists of the following steps:

[0074] 1) The camptothecin solution is passed through diatomaceous earth to remove impurities

[0075] 1.1) 300g of commercially available camptothecin extract (containing 10% camptothecin) is cut into small pieces, placed in a 5L beaker, the ratio of solid to liquid is 1: 10 (g: mL), and 3 L of 90% ethanol was stirred and dissolved for 5 hours;

[0076] 1.2) spread diatomaceous earth evenly in the Buchner funnel, its thickness is 2cm;

[0077] 1.3) Filter the dissolved camptothecin solution with a Buchner funnel, remove solid impurities therein, etc., to obtain filtrate A for subsequent use; collect the filter residue and mix and dissolve the next batch of camptothecin extract for filtration;

[0078] 2) Membrane separator removes impurities from camptothecin solution

[0079] The filtrate A obtained in step 1) is passed through a membrane separator, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com