A kind of cleaning agent and using method thereof

A pore agent and cleaning technology, applied in chemical instruments and methods, detergent compositions, detergent compounding agents, etc., can solve the problems of high cost of electroless copper plating, improve effective adsorption, improve backlight, reduce The effect of holes without copper problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

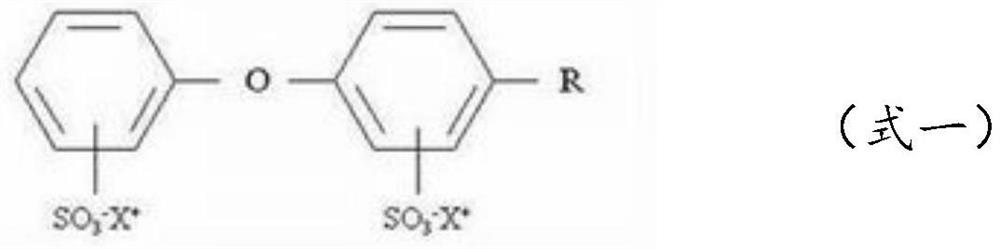

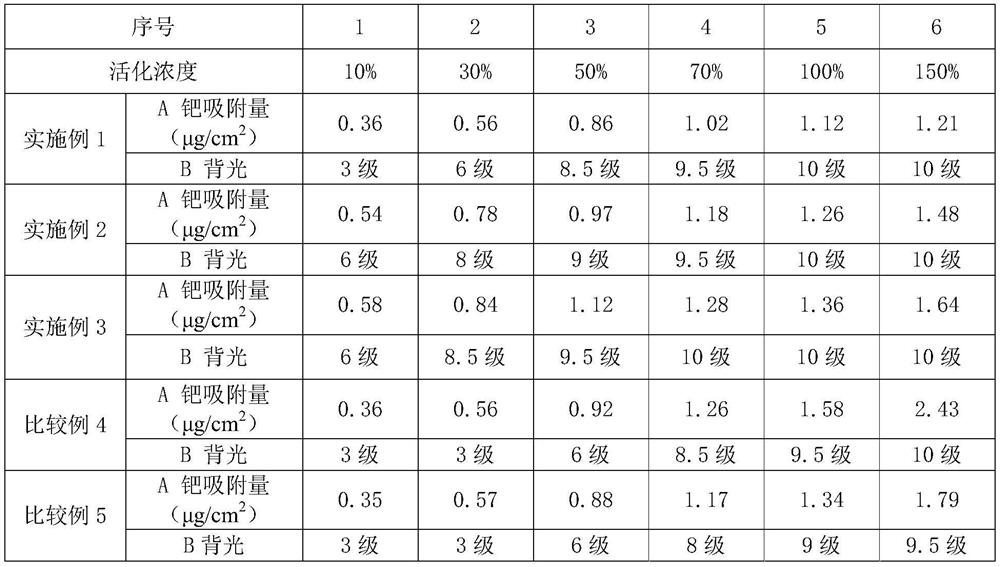

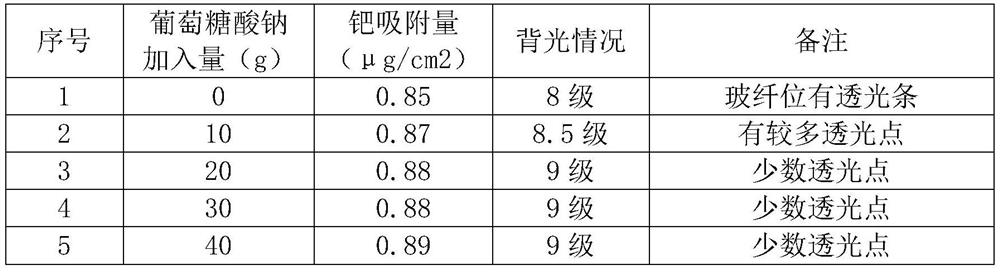

[0041] 1.1. The formula of the cleaning agent is: sodium gluconate 25g / L, ammonium chloride 4g / L, diethylenetriamine 25g / L, isopropanol 20g / L, non-ionic surfactant TRITON X-100 Be the anionic surfactant 0.2g / L of the alkyl diphenyl ether sulfonate group of 0.4g / L, formula one structure, wherein R is C 12 h 25 ; The rest are deionized water, as shown in Table 1.

[0042]1.2. Take 6 pieces of 5×3cm Shengyi Tg170 substrate boards, remove the copper foil on the board surface with etching solution, then soak in the cleaning agent obtained in 1.1, soak at 50°C for 5 minutes, wash with water, and soak them separately In the ionic palladium activation tank with a standard concentration of 10%, 30%, 50%, 70%, 100%, and 150% at a constant temperature of 45°C (the ionic palladium activation standard solution is: 3 pyridinemethanol 1g / L, palladium chloride 0.15 g / L, adjust PH=9.5), take it out after 5 minutes, wash it with water, soak it in a reducing agent solution (dimethylamine boran...

Embodiment 2

[0046] 2.1. The formula of the cleaning agent is: sodium gluconate 25g / L, ammonium chloride 4g / L, diethylenetriamine 25g / L, isopropanol 20g / L, non-ionic surfactant TRITON X-100 Be the anionic surfactant 0.6g / L of the alkyl diphenyl ether sulfonate group of 0.4g / L, formula one structure, wherein R is C 12 h 25 ; The rest are deionized water, as shown in Table 1.

[0047] 2.2. Take 6 pieces of 5×3cm Shengyi Tg170 substrate boards, remove the copper foil on the board surface with etching solution, then soak in the cleaning agent obtained in 2.1, soak at 50°C for 5min, wash with water, and soak them separately In the ionic palladium activation tank with a standard concentration of 10%, 30%, 50%, 70%, 100%, and 150% at a constant temperature of 45°C (the ionic palladium activation standard solution is: 3 pyridinemethanol 1g / L, palladium chloride 0.15 g / L, adjust PH=9.5), take it out after 5 minutes, wash it with water, soak it in a reducing agent solution (dimethylamine borane 0....

Embodiment 3

[0051] 3.1. The formula of the cleaning agent is: sodium gluconate 25g / L, ammonium chloride 4g / L, diethylenetriamine 25g / L, isopropanol 20g / L, non-ionic surfactant TRITON X-100 Be the anionic surfactant 1.0g / L of the alkyl diphenyl ether sulfonate group of 0.4g / L, formula one structure, wherein R is C 12 h 25 ; The rest are deionized water, as shown in Table 1.

[0052] 3.2. Take 6 pieces of 5×3cm Shengyi Tg170 substrate boards, remove the copper foil on the board surface with etching solution, then soak in the cleaning agent obtained in 2.1, soak for 5 minutes at 50°C, wash with water, and soak them separately In the ionic palladium activation tank with a standard concentration of 10%, 30%, 50%, 70%, 100%, and 150% at a constant temperature of 45°C (the ionic palladium activation standard solution is: 3 pyridinemethanol 1g / L, palladium chloride 0.15 g / L, adjust PH=9.5), take it out after 5 minutes, wash it with water, soak it in a reducing agent solution (dimethylamine bora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com