Adsorption and absorption coupling refrigerating appts.

A refrigeration device and adsorber technology, used in refrigerators, refrigeration and liquefaction, adsorption machines, etc., can solve the problems of small refrigeration capacity, low refrigeration efficiency, small adsorption capacity, etc., and achieve increased refrigeration evaporation and refrigeration efficiency. , the effect of increasing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

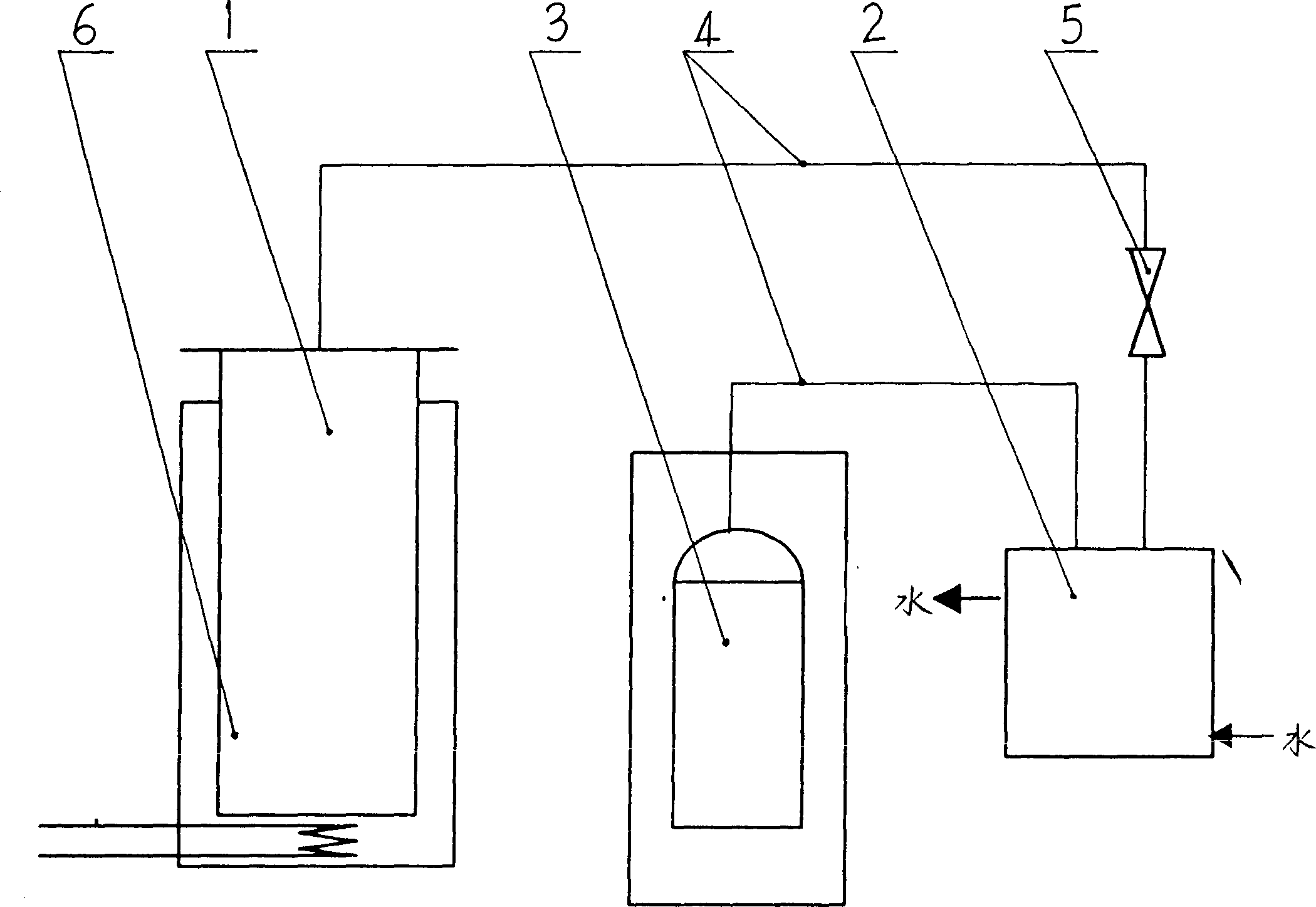

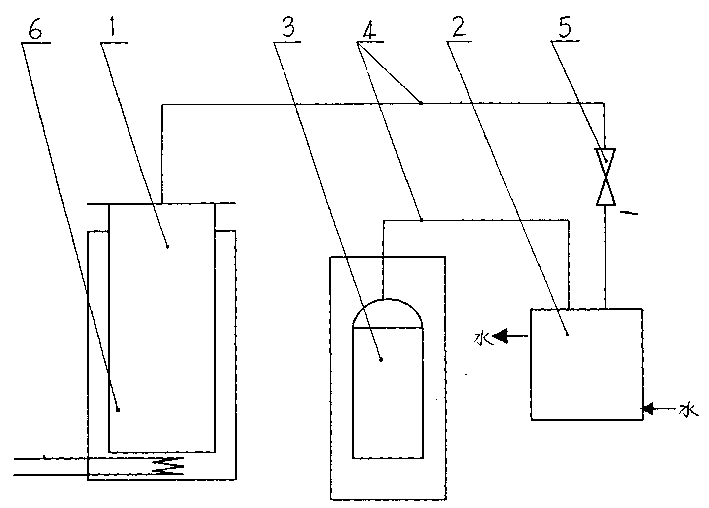

[0016] Such as figure 1 As shown, the adsorption coupling refrigeration device of the present invention is composed of an adsorber 1, a condenser 2, and an evaporator 3 connected in series with a pipeline 4 in sequence, and a valve 5 is installed on the pipeline 4 between the adsorber 1 and the condenser 2, and the adsorber 1 and evaporator 3 are jacketed devices with a sleeve structure. A heating device 6 is installed in the jacket of adsorber 1. The heating medium is heat transfer oil to provide desorption heat. The jacket of evaporator 3 is equipped with medium-cooled coal water to take away Evaporating cooling capacity for refrigeration.

[0017] The mixed working medium in this example is ammonia water, wherein water is the absorbent, ammonia is the refrigerant, and the adsorbent is 13X molecular sieve.

[0018] When working, the ammonia solution is put into the evaporator 3, along with the continuous evaporation and adsorption, the cooling capacity is taken out by the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com