Process for preparing fumaric acid by spraying acid water to benzene anhydride oxidized tail gas

A technology for oxidizing tail gas and fumaric acid, which is applied in the preparation of carboxylate, the preparation of organic compounds, the separation/purification of carboxylic acid compounds, etc., can solve problems such as waste of resources and environmental pollution, reduce labor intensity and eliminate environmental Pollution, the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

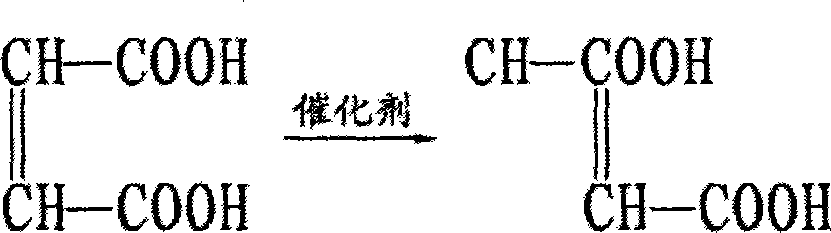

Method used

Image

Examples

Embodiment 1

[0024] The acid water sprayed from the phthalic anhydride plant is filtered through the first stage to remove the undissolved phthalic acid in the acid water, and then enters the first-stage acid pool. Most of the phthalic acid is precipitated here, and the acid water after the phthalic acid is precipitated is filtered through the second stage to remove the precipitated phthalic acid, and the filtrate enters the secondary acid pool. The purpose of acid water cooling and filtration is to remove phthalic acid in acid water and improve the purity of fumaric acid. The recovered phthalic acid is sold as a by-product after drying.

[0025] The acid water after removal of phthalic acid is pumped into the decolorization kettle, and the acid water can be pumped in while steaming, when the pumping volume is 25m 3 When the temperature rises, stop pumping, continue heating and start stirring. When the temperature rises to 65°C, add 60kg of activated carbon and 10-60Kg of diatomaceous eart...

Embodiment 2-8

[0026] Embodiment 2-8: basically the same as the embodiment, except that the process parameters are in accordance with Table 1.

[0027] The processing parameter of table 1 embodiment 2-8

[0028] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com